Whole station plug-and-play secondary equipment component structure of intelligent substation

A technology for smart substations and secondary equipment, applied in distribution substations, substation/distribution device casings, coatings, etc. The effect of improving construction efficiency and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

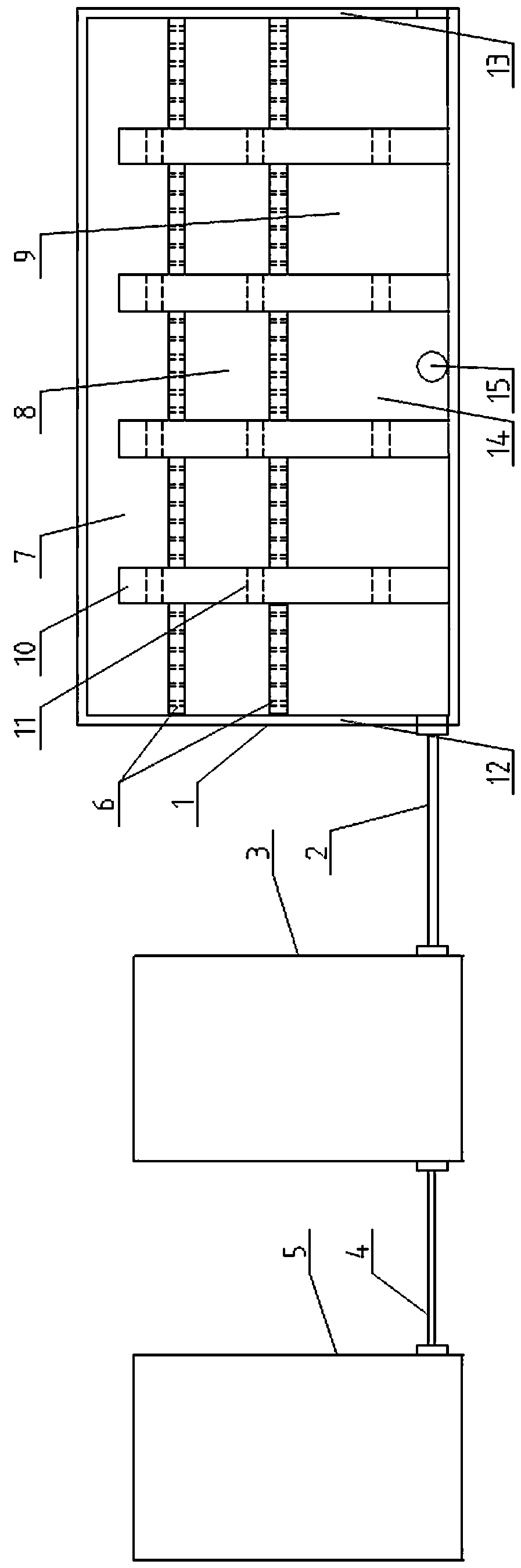

[0032] Such as figure 1 As shown, the integrated plug-and-play secondary equipment component structure of the intelligent substation includes a secondary equipment prefabricated cabin 1, a prefabricated optical cable 2, an on-site control cabinet 3, and a prefabricated cable 4. A plug-and-play connection between the local control cabinets 3 is achieved through the prefabricated optical cable 2, and the prefabricated cable 4 is used for the plug-and-play connection between the local control cabinet 3 and the primary equipment 5 of the substation.

[0033] The internal chamber of the secondary equipment prefabricated cabin 1 is divided from top to bottom by two transverse load-bearing plates 6 into a secondary equipment area 7 at the station control layer, a secondary equipment area 8 at the partition layer, and a wiring area 9 The lateral bearing plate 6 and the inner wall of the secondary equipment prefabricated cabin 1 are supported and fixed by a plurality of vertical support p...

Embodiment 2

[0041] The difference from Example 1 is that: the outer surfaces of the prefabricated secondary equipment cabin and the on-site control cabinet are both coated with a dense coating with paint, which is prepared by the following parts by weight: the suspension agent includes Kaolin and vermiculite powder, the weight ratio of kaolin: vermiculite powder is 6:1, and the particle size of kaolin and vermiculite powder is 200 mesh. The binder is polyvinyl alcohol resin. The additives include nonylphenol polyoxyethylene ether, p-toluenesulfonic acid, and polyimide, and the weight ratio of nonylphenol polyoxyethylene ether: p-toluenesulfonic acid: polyimide is 1:2.5:3.5.

[0042] The preparation method of the coating includes the following steps:

[0043] S1: After mixing the binder and 10 parts by weight of water, place it in a reaction kettle at a temperature of 85°C, a speed of 200r / min, and stirring for 20 minutes;

[0044] S2: After the temperature in the reactor in step S1 drops to 20...

Embodiment 3

[0048] The difference from Example 2 is that the outer surfaces of the prefabricated secondary equipment cabin and the on-site control cabinet are both coated with a dense coating with paint, which is prepared from the following components by weight: Kaolin and vermiculite powder, the weight ratio of kaolin: vermiculite powder is 7:1, and the particle size of kaolin and vermiculite powder is 250 mesh. The binder is polyvinyl alcohol resin. The additives include nonylphenol polyoxyethylene ether, p-toluenesulfonic acid, and polyimide, and the weight ratio of nonylphenol polyoxyethylene ether: p-toluenesulfonic acid: polyimide is 1:2.5:3.5.

[0049] The preparation method of the coating is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com