Catalyst for CO2 synthesized acetylenic acid and preparation method and application thereof

A catalyst and alkyne technology, which is applied in the direction of carboxylate preparation, organic compound preparation, organic compound/hydride/coordination complex catalyst, etc., can solve the problems of large amount of catalyst, reduced catalyst practicability, sensitivity, etc. Achieving high application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

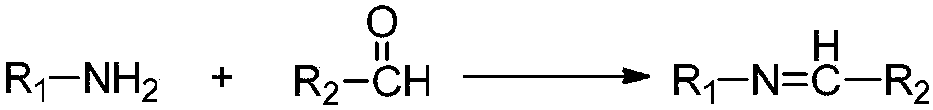

Problems solved by technology

Method used

Image

Examples

Embodiment 1

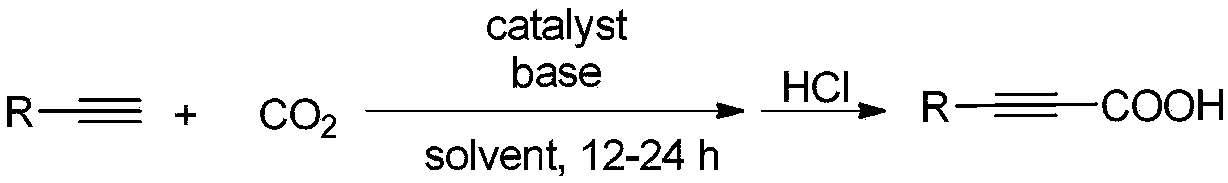

[0026] Ag(1.17wt%) / SiO 2 - Preparation of Schiff catalyst:

[0027] First, measure 1 mL of 3-aminopropyltriethoxysilane and dissolve it in 450 mL of deionized water, and add 2.5 mL of formaldehyde solution with a mass fraction of 37% at 25° C., and continue stirring for 12 h. The resulting white precipitate was filtered, washed with deionized water, and dried at 120 °C for 2 h to obtain the carrier SiO 2 -Schiff. Weigh 200mg SiO 2 -Schiff support, added to 40mL of methanol, and ultrasonically dispersed at room temperature. Then 2 mL of silver nitrate (10 mg) solution was added and sonication was continued for 5 min. After the suspension was separated and washed, the solid product was dried in an oven to obtain the Ag(1.17wt%) / SiO modified by Schiff base. 2 -Schiff catalyst.

Embodiment 2

[0029] Ag(1.36wt%) / SiO 2 - Preparation of Schiff catalyst

[0030] First, measure 1 mL of 3-aminopropyltriethoxysilane and dissolve it in 450 mL of deionized water, and add 2.5 mL of formaldehyde solution with a mass fraction of 37% at 25° C., and continue stirring for 12 h. The resulting white precipitate was filtered, washed with deionized water, and dried at 120 °C for 2 h to obtain the carrier SiO 2 -Schiff. Weigh 200mg SiO 2 -Schiff support, added to 40mL of methanol, and ultrasonically dispersed at room temperature. Then 2 mL of silver nitrate (15 mg) solution was added and sonication was continued for 5 min. After the above-mentioned suspension is separated and washed, the solid product is placed in an oven and dried to obtain the Schiff base-modified Ag (1.36wt%) / SiO 2 -Schiff catalyst.

Embodiment 3

[0032] Ag(1.45wt%) / SiO 2 - Preparation of Schiff catalyst:

[0033] First, measure 1 mL of 3-aminopropyltriethoxysilane and dissolve it in 450 mL of deionized water, and add 2.5 mL of formaldehyde solution with a mass fraction of 37% at 25° C., and continue stirring for 12 h. The resulting white precipitate was filtered, washed with deionized water, and dried at 120 °C for 2 h to obtain the carrier SiO 2 -Schiff. Weigh 200mg SiO 2 -Schiff support, added to 40mL of methanol, and ultrasonically dispersed at room temperature. Then 2 mL of silver nitrate (20 mg) solution was added and sonication was continued for 5 min. After the above-mentioned suspension is separated and washed, the solid product is placed in an oven and dried to obtain the Schiff base-modified Ag (1.45wt%) / SiO 2 -Schiff catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com