Anti-ultraviolet treatment method for rubber gloves

A kind of rubber gloves, anti-ultraviolet technology, applied in the direction of radiation-absorbing coatings, coatings, thixotropic coatings, etc., can solve the problems of easy dissolution, poor compatibility, limited long-lasting anti-ultraviolet aging, etc., to improve absorption and reduce aging speed. , Increase the effect of anti-ultraviolet ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

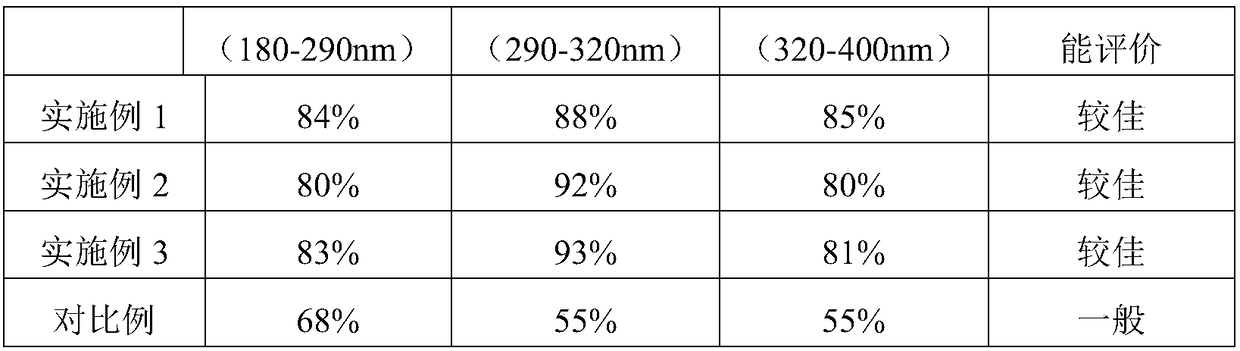

Embodiment 1

[0020] An anti-ultraviolet treatment method for rubber gloves, comprising the following steps:

[0021] (1) Preparation of microlatex of anti-ultraviolet composite coating: first, mix mica powder and polyester copolymer containing hindered amine side groups at a mass ratio of 10:1, add to 30 times the volume of deionized water, and add solvent volume at the same time One-third of 3,3,4,4-tetrafluoropyrrolidine, co-emulsifier, dispersant, ultrasonic device at 400W for 160s to obtain a dispersion liquid; first cool to room temperature for 2 hours and then heat up to 65°C for heat preservation After 20 minutes, carry out 1500r / min high-speed stirring for 6 minutes; add emulsifier while stirring, continue to place it in an ultrasonic device for 300W ultrasonic treatment for 100s, add the initiator and then copolymerize at 120°C overnight to obtain an anti-ultraviolet composite coating microlatex; the co-emulsifier It is a mixture of sodium alginate and sodium acrylate with a mass ...

Embodiment 2

[0026] An anti-ultraviolet treatment method for rubber gloves, comprising the following steps:

[0027] (1) Preparation of microlatex of anti-ultraviolet composite coating: firstly, mica powder and polyester copolymer containing hindered amine side groups are mixed in a mass ratio of 10:1, added to 50 times the volume of deionized water, and the volume of solvent is added at the same time One-third of 3,3,4,4-tetrafluoropyrrolidine, co-emulsifier, dispersant, ultrasonic device at 400W for 160s to obtain a dispersion liquid; first cool to room temperature for 2-3 hours and then heat up to 65°C After heating and heat preservation for 20 minutes, carry out 1500r / min high-speed stirring for 6 minutes; add emulsifier while stirring, continue to place in an ultrasonic device for 300W ultrasonic treatment for 100s, and after adding initiator, 120°C copolymerization reaction overnight to obtain an anti-ultraviolet composite coating microlatex; The emulsifier is a mixture of sodium alg...

Embodiment 3

[0032] An anti-ultraviolet treatment method for rubber gloves, comprising the following steps:

[0033] (1) Preparation of microlatex of anti-ultraviolet composite coating: firstly, mica powder and polyester copolymer containing hindered amine side groups are mixed in a mass ratio of 10:1, added to 40 times the volume of deionized water, and the volume of solvent is added at the same time One-third of 3,3,4,4-tetrafluoropyrrolidine, co-emulsifier, dispersant, ultrasonic device at 400W for 160s to obtain a dispersion liquid; first cool to room temperature for 2.5h and then heat up to 65°C for heating After heat preservation for 20 minutes, carry out 1500r / min high-speed stirring for 6 minutes; add emulsifier while stirring, continue to place in an ultrasonic device for 300W ultrasonic treatment for 100s, add the initiator and copolymerize at 120°C overnight to obtain an anti-ultraviolet composite coating microlatex; the emulsification aid The agent is a mixture of sodium algina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com