High-elasticity modified epoxy seam sealing adhesive

An epoxy-sealing, high-elasticity technology, applied in the field of epoxy adhesives, can solve the problems of viscosity drop, restricted use conditions, use occasions, storage and use inconvenience, etc., to increase the surface adsorption force and improve the overall adhesive ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

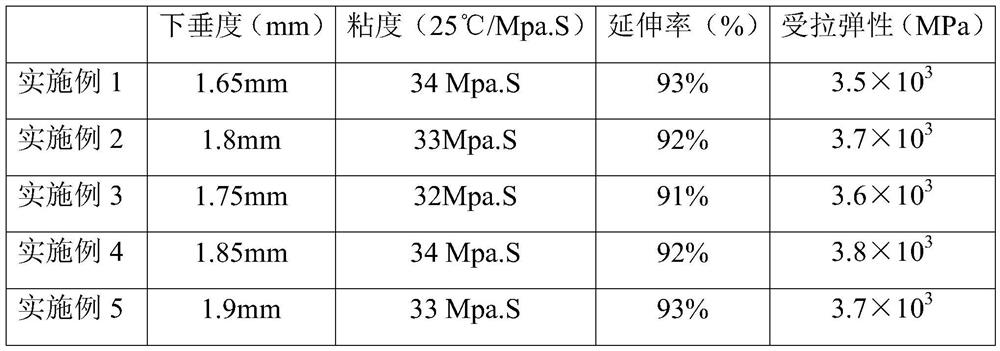

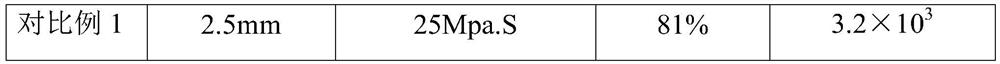

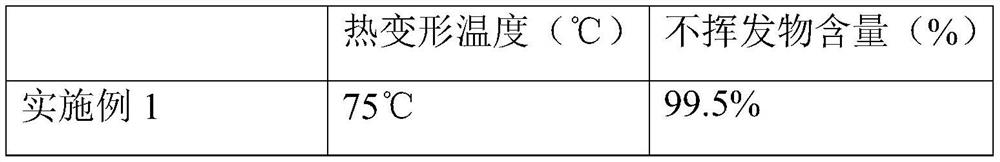

Examples

Embodiment 1

[0021] A highly elastic modified epoxy sealant, comprising component A and component B with a volume ratio of 2:1;

[0022] In parts by mass, component A includes 80 parts of bisphenol A type epoxy resin, 15 parts of dodecyl to myristyl glycidyl ether, 40 parts of epoxy-terminated polyurethane, 50 parts of 800 mesh silicon powder, 60 parts 2000 mesh silica powder, 5 parts of gas-phase hydrophobic silica;

[0023] In terms of parts by mass, component B includes 20 parts of polyetheramine D230, 20 parts of polyetheramine D400, 2 parts of accelerator, 20 parts of nonylphenol modified hexamethylenediamine, 2 parts of γ-glycidyl propyl trimethyl Oxysilane, 20 parts of 800-mesh silicon micropowder, 40 parts of 2000-mesh silicon micropowder, and 5 parts of gas-phase hydrophobic silica.

[0024] The preparation method of this highly elastic modified epoxy sealant is as follows:

[0025] S1. Preparation of component A: Pour the substances of component A into the stirring and dispersi...

Embodiment 2

[0029] A highly elastic modified epoxy sealant, comprising component A and component B with a volume ratio of 3:1;

[0030] In terms of parts by mass, component A includes 120 parts of bisphenol A epoxy resin, 20 parts of dodecyl to myristyl glycidyl ether, 40 parts of epoxy-terminated polyurethane, 60 parts of 800-mesh silicon micropowder, 70 parts 2000 mesh silica powder, 2 parts gas-phase hydrophobic silica;

[0031] In terms of parts by mass, component B includes 15 parts of polyetheramine D230, 15 parts of polyetheramine D400, 2 parts of accelerator, 20 parts of nonylphenol modified hexamethylenediamine, 2 parts of γ-glycidyl propyl trimethyl Oxysilane, 20 parts of 800-mesh silicon micropowder, 30 parts of 2000-mesh silicon micropowder, and 2 parts of gas-phase hydrophobic silica.

Embodiment 3

[0033] A highly elastic modified epoxy sealant, comprising component A and component B with a volume ratio of 3:1;

[0034] In terms of parts by mass, component A includes 100 parts of bisphenol A type epoxy resin, 15 parts of dodecyl to myristyl glycidyl ether, 40 parts of epoxy-terminated polyurethane, 70 parts of 800-mesh silicon micropowder, 60 parts 2000 mesh silica powder, 5 parts of gas-phase hydrophobic silica;

[0035] In parts by mass, component B includes 20 parts of polyetheramine D230, 20 parts of polyetheramine D400, 2 parts of accelerator, 20 parts of nonylphenol modified ethylenediamine, 2 parts of γ-glycidyl propyl trimethyl Oxysilane, 20 parts of 800-mesh silicon micropowder, 40 parts of 2000-mesh silicon micropowder, and 5 parts of gas-phase hydrophobic silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com