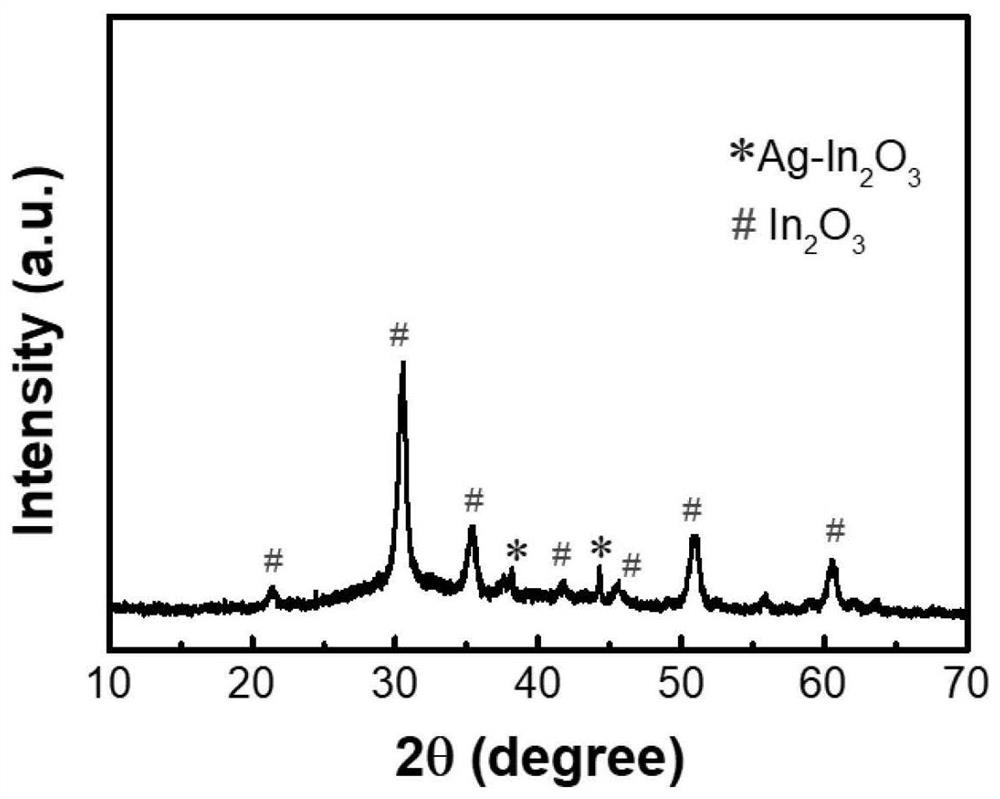

Silver-modified micron tubular indium oxide nitrogen dioxide gas-sensitive material and preparation method thereof

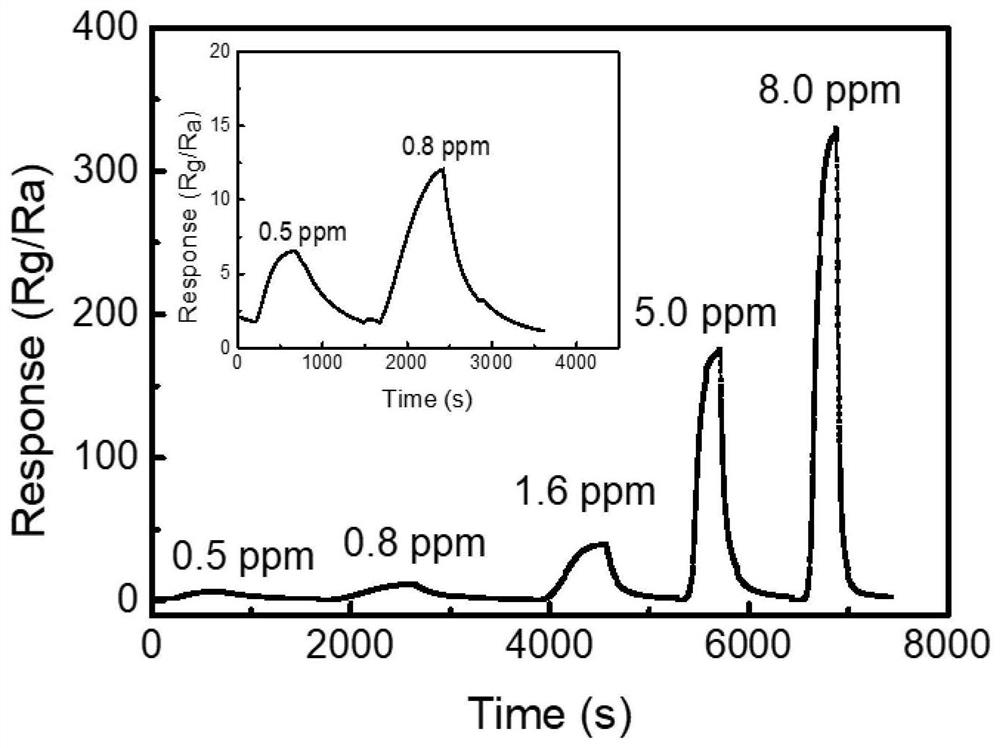

A nitrogen dioxide, indium oxide technology, applied in the direction of analyzing materials, material analysis by electromagnetic means, measuring devices, etc., can solve problems such as reducing the working temperature of gas-sensitive materials, and achieve faster response recovery speed, enhanced sensitivity, and improved electronic The effect of the exchange reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

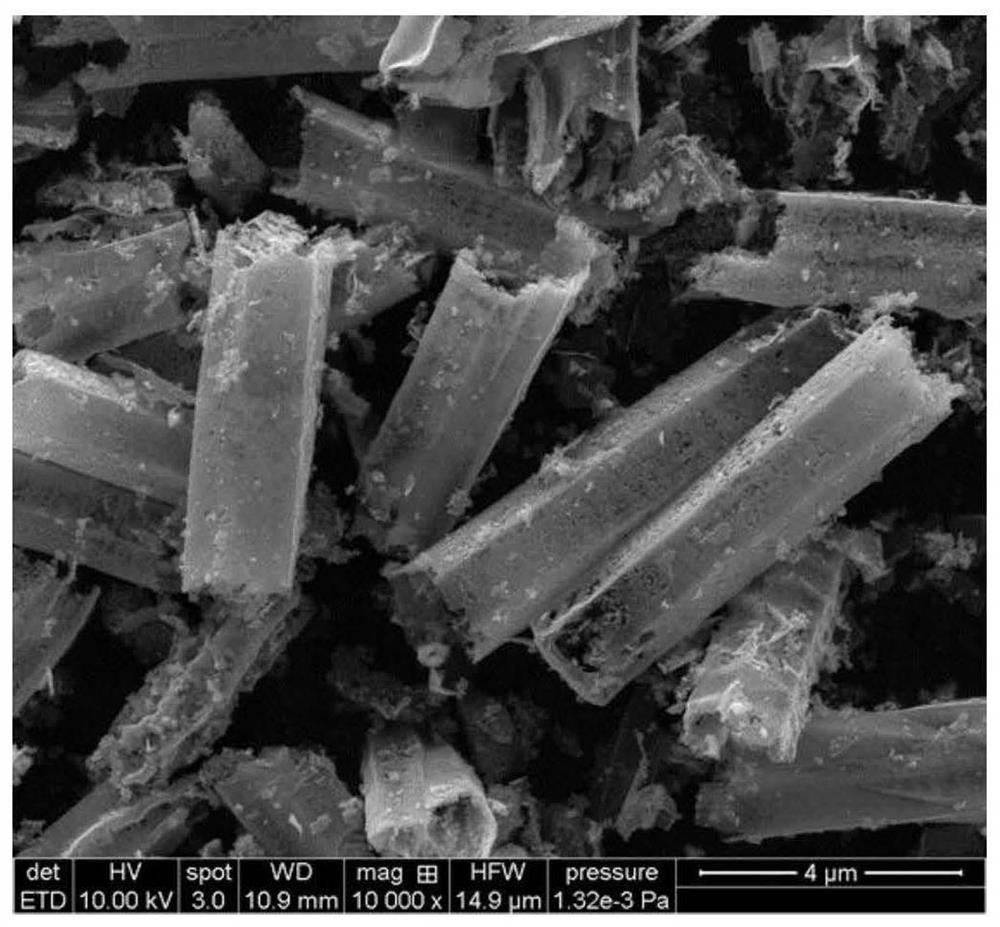

[0028] A method for preparing a silver-modified micron tubular indium oxide nitrogen dioxide gas-sensitive material:

[0029] (1) Dissolve 0.179g of 1,4-terephthalic acid in 60mL of N,N-dimethylformamide (DMF), stir until it becomes a transparent solution, then add 0.383g of indium nitrate hydrate (In(NO 3 ) 3 ·3H 2O) Disperse, sonicate until dissolved. The above solution was moved into a reactor, and the reactor was placed in an oven at 100°C for reaction heat synthesis for 4 hours, centrifuged, washed and dried at 80°C for 24 hours to obtain a precursor of micron tubular indium oxide.

[0030] (2) The precursor of micron tubular indium oxide prepared in step (1) was heated to 450° C. at a heating rate of 5° C. / min, and calcined for 4 hours to obtain micron tubular indium oxide.

[0031] (3) Weigh 80 mg (0.288 mmol) of the micron tubular indium oxide prepared in step (2) and disperse it in 100 mL of silver nitrate (concentration of silver nitrate is 0.5 mmol / L) and 1.5 mL ...

Embodiment 2

[0036] (1) Dissolve 0.45g of 1,4-terephthalic acid in 80mL of N,N-dimethylformamide (DMF), stir until it becomes a transparent solution, then add 0.96g of indium nitrate hydrate (In(NO 3 ) 3 ·3H 2 O) Disperse, sonicate until dissolved. The above solution was moved into a reactor, and the reactor was placed in an oven at 100°C for thermal synthesis for 14 hours, centrifuged, washed and dried at 80°C for 24 hours to obtain a precursor of micron tubular indium oxide.

[0037] (2) The precursor of micron tubular indium oxide prepared in step (1) was heated up to 475° C. at a heating rate of 2° C. / min, and calcined for 5 hours to obtain micron tubular indium oxide.

[0038] (3) Weigh 80 mg of micron tubular indium oxide prepared in step (2) and disperse it in 90 mL of silver nitrate (concentration of silver nitrate is 0.5 mmol / L) and 2 mL of sodium citrate (concentration of sodium citrate is 30 mmol / L) In the mixed solution, stir for 30min until fully dissolved to obtain solutio...

Embodiment 3

[0040] (1) Dissolve 0.21g of 1,4-terephthalic acid in 70mL of N,N-dimethylformamide (DMF), stir until it becomes a transparent solution, then add 0.45g of indium nitrate hydrate (In(NO 3 ) 3 ·3H 2 O) Disperse, sonicate until dissolved. The above solution was moved into a reaction kettle, and the reaction kettle was placed in an oven at 90°C for 24 hours of thermal synthesis, centrifuged, washed and dried at 80°C for 24 hours to obtain a precursor of micron tubular indium oxide.

[0041] (2) The precursor of the micron tubular indium oxide prepared in step (1) was heated up to 500° C. at a heating rate of 4° C. / min, and calcined for 4 hours to obtain the micron tubular indium oxide.

[0042] (3) Weigh 80 mg of micron tubular indium oxide prepared in step (2) and disperse them in 70 mL of silver nitrate (concentration of silver nitrate is 0.5 mmol / L) and 1.5 mL of sodium citrate (concentration of sodium citrate is 30 mmol / L) ) in the mixed solution, stirred for 30min until fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com