Hierarchical structure ZnO@ZnO nano-composite gas-sensitive material and preparation method thereof

A hierarchical structure and nano-composite technology, which is applied in the direction of analyzing materials, material resistance, and material analysis through electromagnetic means, can solve the problems of easy growth and immature application, achieve low detection limit and increase space active sites , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 61.5mg of 2-methylimidazole in a mixed solution of 60mL N,N-dimethylformamide (DMF) and water, where DMF: H 2 O=3:1, sonicate for 5 minutes to prepare the precursor solution; weigh 132 mg of zinc oxide nanopowder, add it to the prepared precursor solution, put all the solutions into a 100mL reactor, and heat The reactant was reacted for 24 hours, and then the reactant was taken out, filtered, washed with ethanol for several times, and then dried to obtain a hierarchical structure ZnO@ZnO precursor material; the obtained precursor material was placed in a tube furnace and heated at 500 ℃ calcination, the heating rate is 2 ℃ / min, the temperature is maintained for 1h, and the temperature is naturally lowered to room temperature to obtain a ZnO@ZnO nanocomposite gas-sensing material with a hierarchical structure.

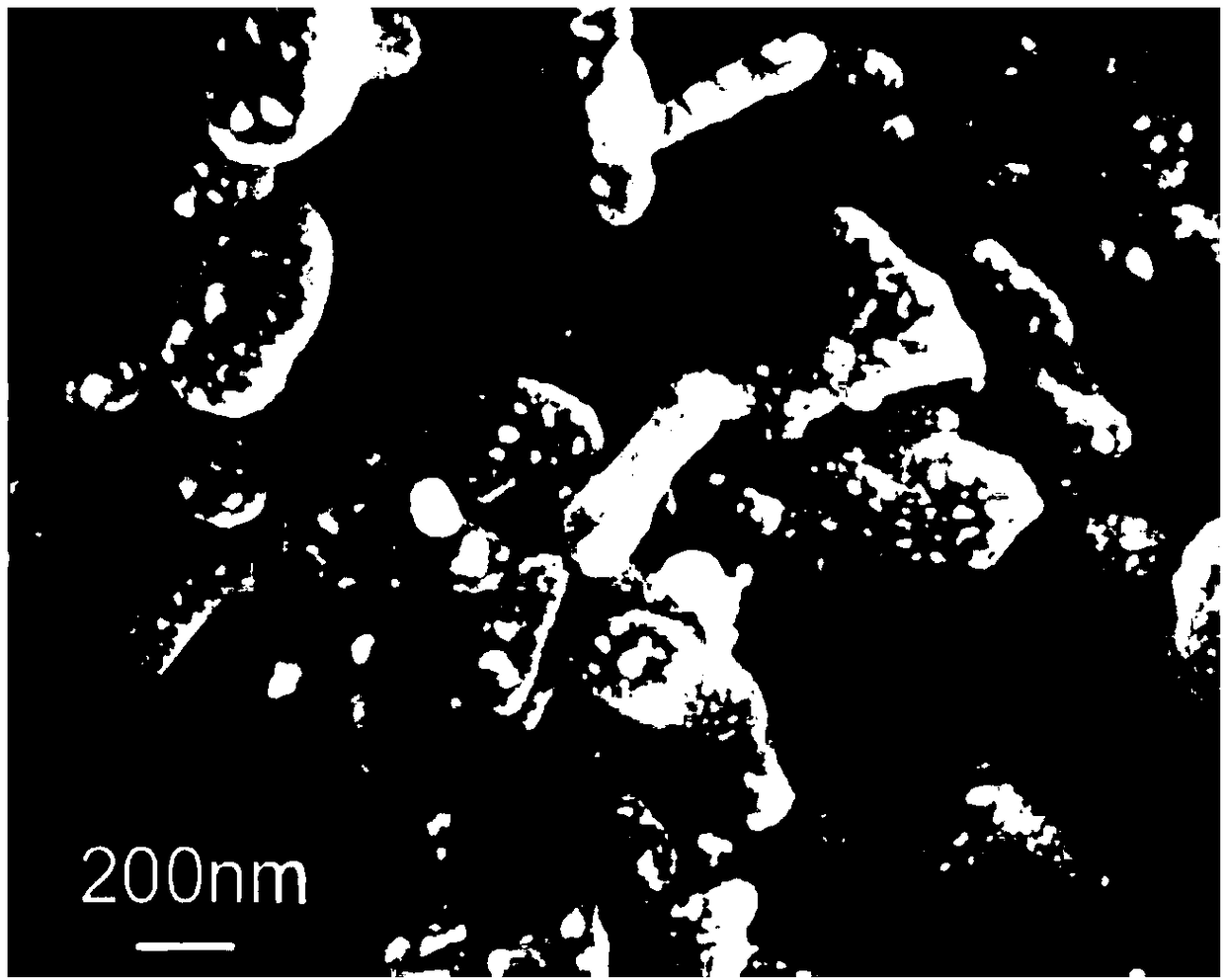

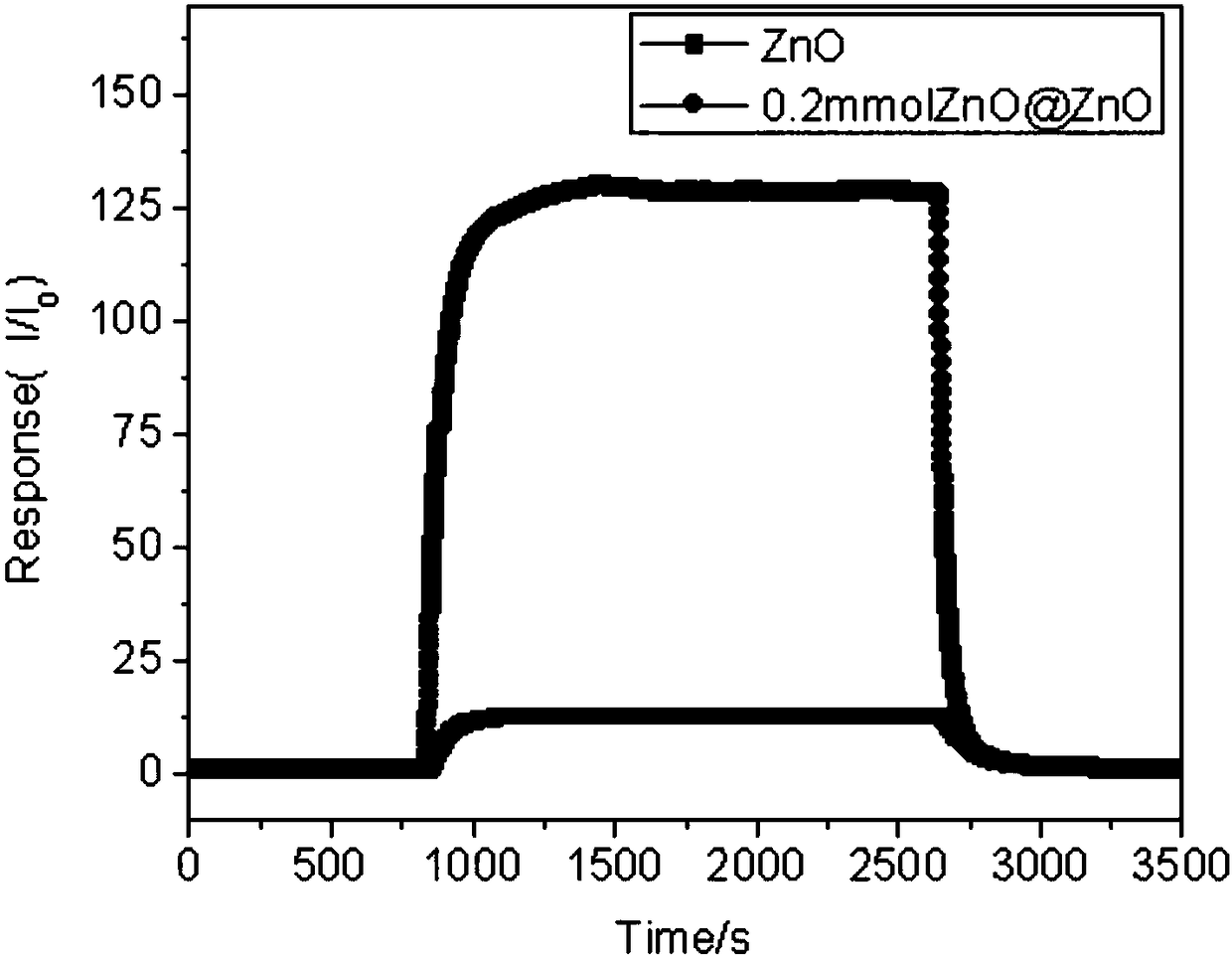

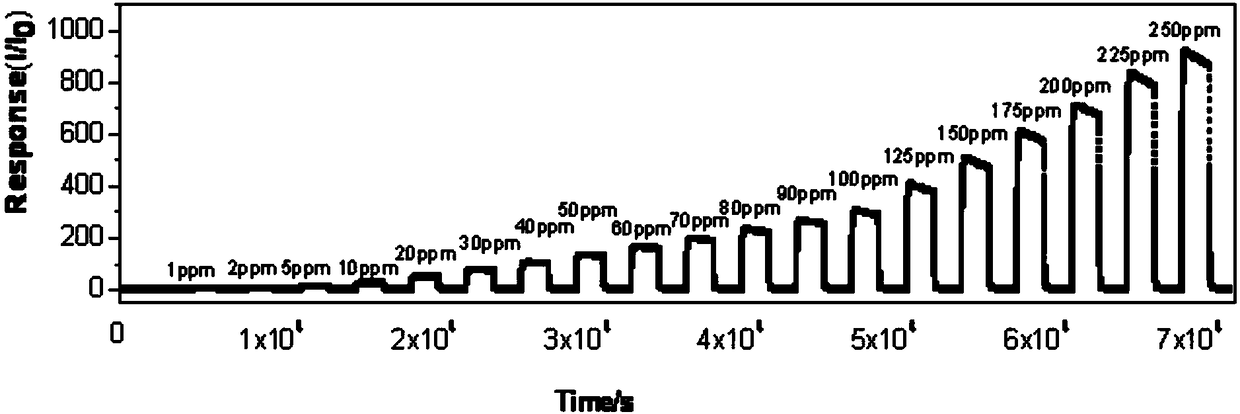

[0029] The SEM image of the prepared hierarchical structure ZnO@ZnO nanocomposite gas-sensing material is shown in the attached figure 1 shown by figu...

Embodiment 2

[0031] Dissolve 61.5mg of 2-methylimidazole in a mixed solution of 60mL N,N-dimethylformamide (DMF) and water, where DMF: H 2 O=3:1, sonicate for 5 minutes to prepare the precursor solution; weigh 132 mg of zinc oxide nanopowder, add it to the prepared precursor solution, put all the solutions into a 100mL reactor, and heat The reactant was reacted for 24 hours, and then the reactant was taken out, filtered, washed with ethanol for several times, and then dried to obtain a hierarchical structure ZnO@ZnO precursor material; ℃ calcination, the heating rate was 2 ℃ / min, the temperature was maintained for 1h, and the temperature was naturally cooled to room temperature to obtain a ZnO@ZnO nanocomposite gas-sensing material with a hierarchical structure. At 375 ℃, the resistance response rate to ethanol with a concentration of 50ppm was 36.8.

Embodiment 3

[0033] Dissolve 30.75mg of 2-methylimidazole in a mixed solution of 60mL N,N-dimethylformamide (DMF) and water, where DMF: H 2 O=3:1, sonicate for 5 minutes to prepare the precursor solution; weigh 132 mg of zinc oxide nanopowder, add it to the prepared precursor solution, put all the solutions into a 100mL reactor, and heat After reacting for 24 hours, the reactant was taken out, filtered, washed with ethanol for several times, and then dried to obtain the ZnO@ZnO precursor material with hierarchical structure; the obtained precursor material was placed in a tube furnace and heated at 600 ℃ calcination, the heating rate was 2 ℃ / min, the temperature was maintained for 1 h, and the temperature was naturally cooled to room temperature to obtain a ZnO@ZnO nanocomposite gas-sensing material with a hierarchical structure. At 375 ℃, the resistance response rate to ethanol with a concentration of 50 ppm was 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com