Silver and indium oxide composite nanorod array formaldehyde air-sensitive material and preparation method thereof

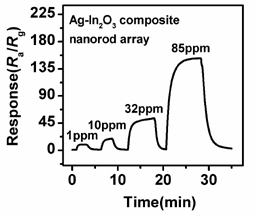

A technology of nanorod array and indium oxide, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., to achieve the effects of reducing sintering, enhancing thermal stability, and accelerating response and recovery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

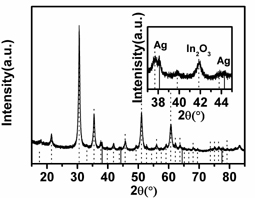

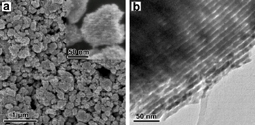

[0027] Example 1: A silver-indium oxide composite nanorod array formaldehyde gas-sensitive material, the formaldehyde gas-sensitive material is formed by a hexagonal periodic arrangement of silver-indium oxide composite nanorods, and the length between the nanorods is 2-5nm connection, the diameter of the nanorod is 9 nm, the length is 20-500 nm, and the mass percentage of the silver in the composite is 9.4%.

[0028] The preparation method of the silver-indium oxide composite nanorod array formaldehyde gas-sensitive material is as follows:

[0029] Mix 8.0g of surfactant P123, 60g of water and 240g of 2 M hydrochloric acid at 35°C, stir for 12 hours until all the surfactants are dissolved and dispersed evenly, then add 16.72g of ethyl orthosilicate TEOS, stir for 5 minutes After that, it was transferred to a polytetrafluoroethylene bottle and left to stand in an oven at 35°C for 20 hours, followed by hydrothermal reaction at 130°C for 5 days, after natural cooling, suction fi...

Embodiment 2

[0033] Example 2: A silver-indium oxide composite nanorod array formaldehyde gas-sensitive material, the formaldehyde gas-sensitive material is formed by a hexagonal periodic arrangement of silver-indium oxide composite nanorods, and the length between the nanorods is 2-5nm connection, the diameter of the nanorod is 9nm, the length is 20-500nm, and the mass percentage of the silver in the composite is 0.2%.

[0034] The preparation method of the silver-indium oxide composite nanorod array formaldehyde gas-sensitive material is as follows:

[0035] Mix 8.0g of surfactant P123, 60g of water and 240g of 2 M hydrochloric acid at 35°C, stir for 12 hours until all the surfactants are dissolved and dispersed evenly, then add 16.72g of ethyl orthosilicate TEOS, stir for 5 minutes Afterwards, it was transferred to a polytetrafluoroethylene bottle and left to stand in an oven at 35°C for 20 hours, followed by hydrothermal reaction at 130°C for 5 days, after natural cooling, suction filt...

Embodiment 3

[0037] Embodiment 3: A formaldehyde gas-sensing material of a silver-indium oxide composite nanorod array, the formaldehyde gas-sensing material is formed by a hexagonal periodic arrangement of silver-indium oxide composite nanorods, and the length between the nanorods is 2-5nm connection, the diameter of the nanorod is 9nm, the length is 20-500nm, and the mass percentage of the silver in the composite is 20%.

[0038] The preparation method of the silver-indium oxide composite nanorod array formaldehyde gas-sensitive material is as follows:

[0039] Mix 8.0g of surfactant P123, 60g of water and 240g of 2 M hydrochloric acid at 35°C, stir for 12 hours until all the surfactants are dissolved and dispersed evenly, then add 16.72g of ethyl orthosilicate TEOS, stir for 5 minutes After that, it was transferred to a polytetrafluoroethylene bottle and left to stand in an oven at 35°C for 20 hours, followed by hydrothermal reaction at 130°C for 5 days, after natural cooling, suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com