Composite nanoscale semiconductor material AZO/Nb2O5/Pt gas-sensitive element and preparation method thereof

A nano-semiconductor and gas sensor technology, applied in nanotechnology, nanotechnology, analytical materials, etc., can solve the problem of high detection limit of gas sensors, meet the requirements of trace concentration detection, fast response recovery, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

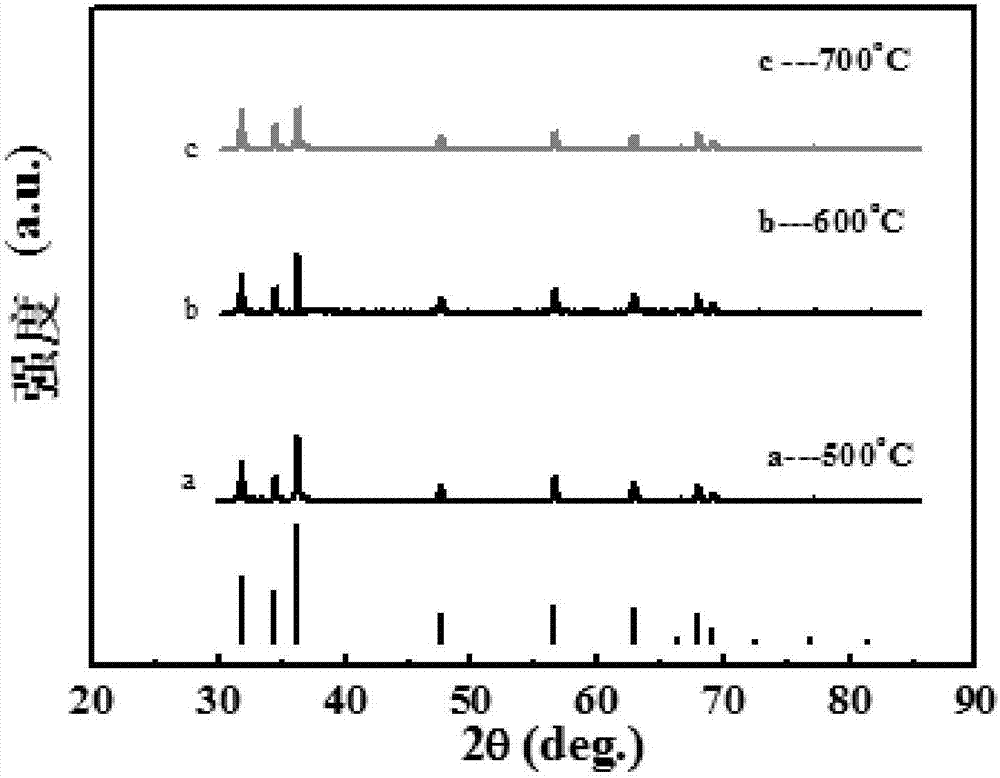

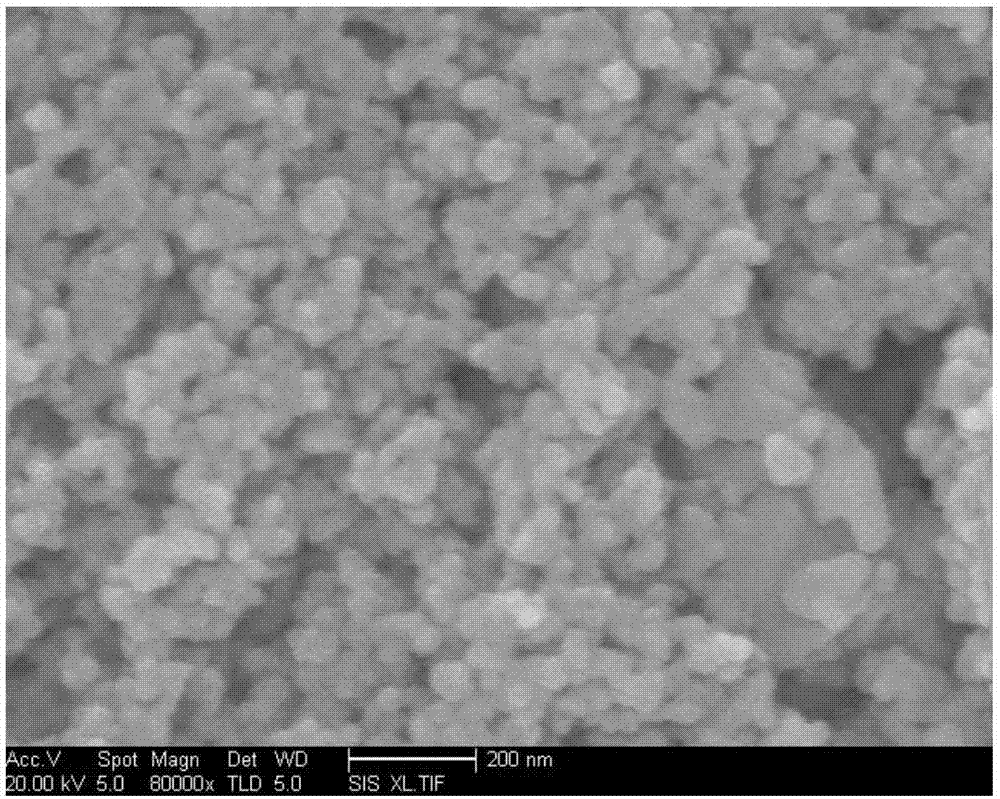

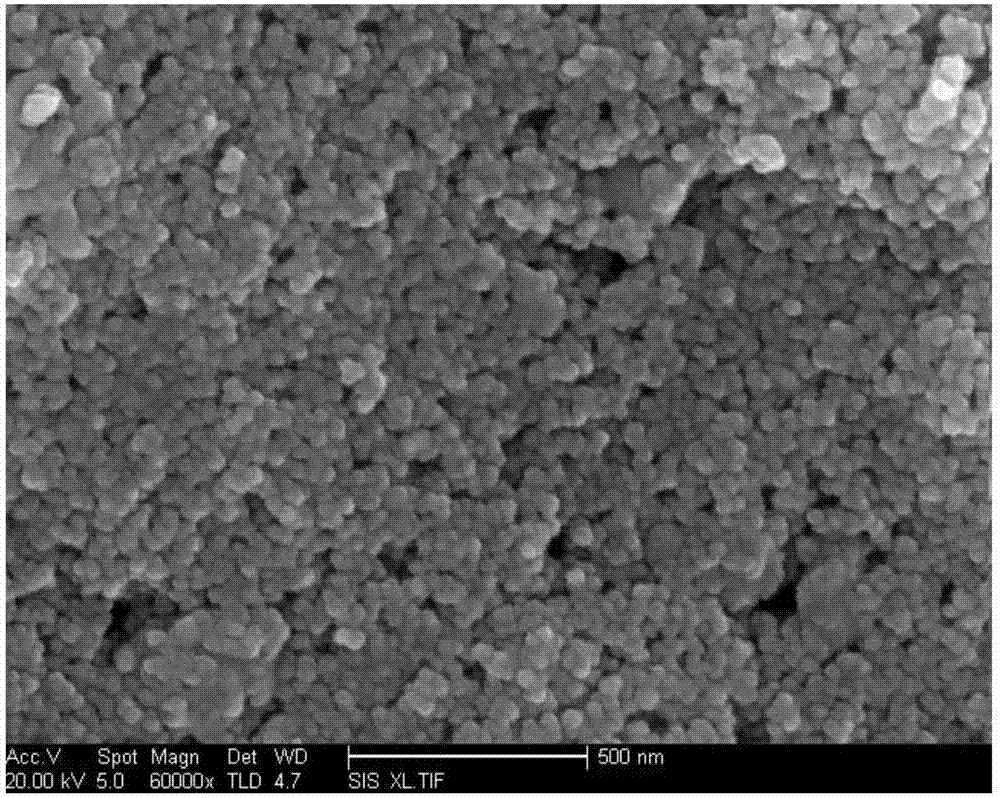

[0017] Specific implementation mode one: the composite nano-semiconductor material AZO / Nb of this embodiment mode 2 o 5 / Pt gas sensor is in Al 2 o 3 A layer of nano-semiconductor material AZO / Nb loaded on a ceramic tube 2 o 5 / Pt, among which the nano-semiconductor material AZO / Nb 2 o 5 The molar ratio of Zn and Nb in the / Pt is (8-9):1; the mass of Pt accounts for 3%-5% of the total mass of the composite nano-semiconductor material.

specific Embodiment approach 2

[0018] Specific implementation mode two: the composite nano-semiconductor material AZO / Nb described in the first implementation mode 2 o 5 The preparation method of the gas sensor of / Pt, carries out according to the following steps:

[0019] Step 1: According to the mol ratio of zinc acetate and hexamethylenetetramine is 1: (2~3), the amount of substance of soluble aluminum salt is 3%~5% of zinc acetate, zinc acetate, hexamethylenetetramine Tetramine and soluble aluminum salts are added to water, mixed evenly, then added to the hydrothermal kettle, and then the hydrothermal kettle is placed in a furnace at a temperature of 120-130°C to react for 12-15 hours, and the product obtained by the reaction is then centrifugally cleaned, Dried to obtain AZO powder;

[0020] Step 2: Weigh AZO powder and Nb 2 o 5 powder, where Zn and Nb in AZO powder 2 o 5 The molar ratio of Nb in the powder is 8-9:1, first dissolve the AZO powder in deionized water to obtain the AZO solution; the...

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 2 in that the temperature of the hydrothermal reaction in step 1 is 125° C., and the reaction time is 13 hours. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com