Isopropanol gas-sensitive element based on ZnSnO3 nanospheres of perovskite structures and preparation method of element

A technology of perovskite structure and gas sensor, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for sensing, can solve the problems of high working temperature, low sensitivity, complex manufacturing process, etc., and achieve small particle size , high sensitivity, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

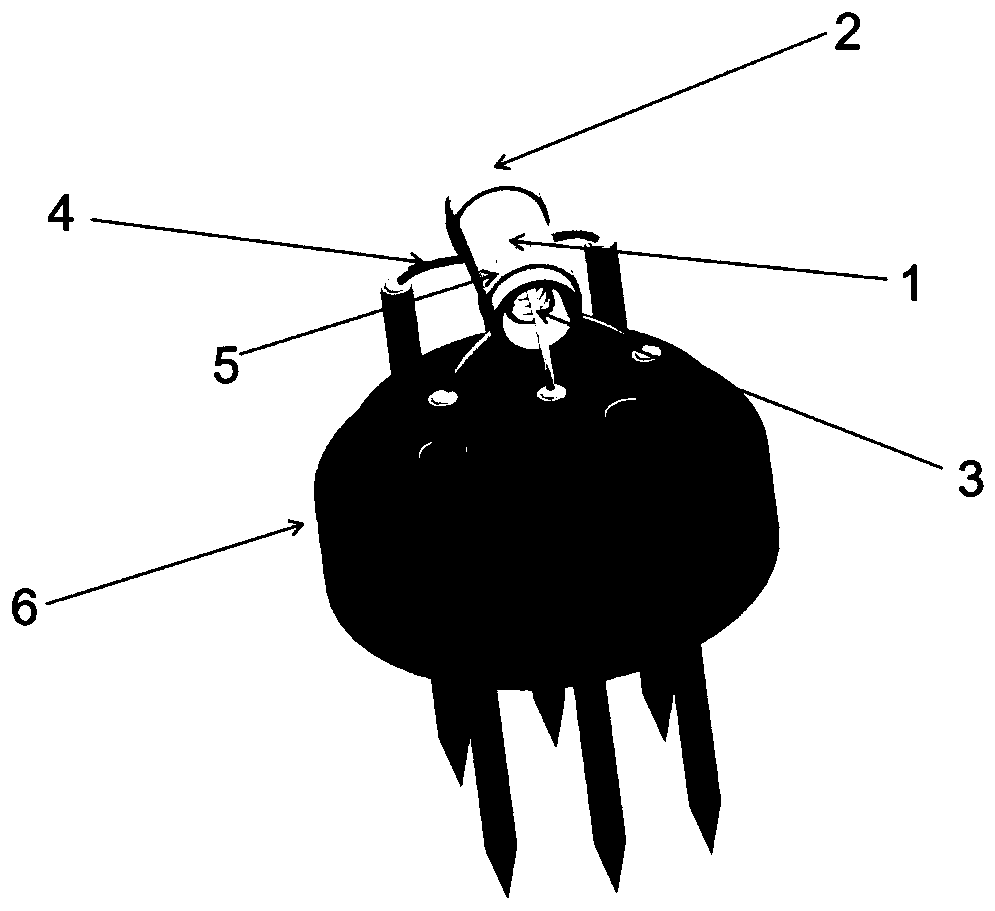

[0035] Based on the perovskite structure ZnSnO of the present embodiment 3 Nanosphere ppb level isopropanol gas sensor, its main structure schematic diagram is as follows figure 1 As shown, it includes a gas-sensitive coating 1, a ceramic tube 2, a heating wire 3, a platinum wire 4, a gold electrode 5, and a base 6, wherein the gold electrode 5 is wound on the surface of the ceramic tube 2 and welded to form a ceramic tube electrode. The sensitive coating 1 is coated on the surface of the whole ceramic tube 2 and the gold electrode 5; the heating wire 3 traverses in the ceramic tube 2 and is welded on the heating electrode of the base 6; the platinum wire 4 is connected with the gold electrode 5, and The four measuring electrodes welded on the base 6 are made based on the perovskite structure ZnSnO 3 Nanosphere ppb grade isopropanol gas sensor. The material of the gas sensitive coating 1 is ZnSnO 3 Nanospheres, the nanospheres have a diameter of 500±50nm, good dispersion, s...

Embodiment 2

[0047] Based on the perovskite structure ZnSnO of the present embodiment 3 The schematic diagram of the main structure of the ppb level isopropanol gas sensor of the nanosphere is as shown in the figure. figure 1 As shown, it includes a gas-sensitive coating 1, a ceramic tube 2, a heating wire 3, a platinum wire 4, a gold electrode 5, and a base 6, wherein the gold electrode 5 is wound on the surface of the ceramic tube 2 and welded to form a ceramic tube electrode. The sensitive coating 1 is coated on the surface of the whole ceramic tube 2 and the gold electrode 5; the heating wire 3 traverses in the ceramic tube 2 and is welded on the heating electrode of the base 6; the platinum wire 4 is connected with the gold electrode 5, and The four measuring electrodes welded on the base 6 are made based on the perovskite structure ZnSnO 3 Nanosphere ppb grade isopropanol gas sensor. The gas-sensitive coating 1 is ZnSnO 3 Nanospheres, the nanospheres have a diameter of 500±50nm, g...

Embodiment 3

[0055] Based on the perovskite structure ZnSnO of the present embodiment 3 The schematic diagram of the main structure of the ppb level isopropanol gas sensor of the nanosphere is as shown in the figure. figure 1 As shown, it includes a gas-sensitive coating 1, a ceramic tube 2, a heating wire 3, a platinum wire 4, a gold electrode 5, and a base 6, wherein the gold electrode 5 is wound on the surface of the ceramic tube 2 and welded to form a ceramic tube electrode. The sensitive coating 1 is coated on the surface of the whole ceramic tube 2 and the gold electrode 5; the heating wire 3 traverses in the ceramic tube 2 and is welded on the heating electrode of the base 6; the platinum wire 4 is connected with the gold electrode 5, and Welded on the four measuring electrodes of the base 6, made based on the perovskite structure ZnSnO 3 Nanosphere ppb grade isopropanol gas sensor. The gas-sensitive coating 1 is ZnSnO 3 Nanospheres, the nanospheres have a diameter of 500±50nm, g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com