Polyurethane caulking compound applied to ballastless tracks of high-speed railways and preparation method of polyurethane caulking compound

A high-speed railway, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of high production cost, short service life, increased maintenance cost, etc. Good anti-displacement deformation ability, high production efficiency, easy to repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] 1) Preparation of isocyanate-terminated prepolymer

[0047] A. According to the design requirements, within the range of parts by weight of the above-mentioned components, add 350 parts of polyether polyol with a water content of less than 5 / 10,000, and 7 parts of anti-aging agents 1130 and 292 respectively into the reactor. Start stirring, and heat up, raise the temperature to 65-70°C, then take 50 parts of solvent, stir evenly, add 100 parts of MDI, continue stirring for 0.5 hours; then raise the temperature to 75-80°C, and react for 1.5 hours;

[0048] B. Keep 75-80°C and add 240 parts of the aforementioned polyether polyol, then react at 80°C for 1.5 hours;

[0049] C. Add 0.5 parts of organotin catalyst, 50 parts of solvent, 50 parts of dewatering agent, 0.5 part of defoamer, 0.5 part of coupling agent, and complete the preparation of prepolymer after timing for 0.5 hours;

[0050] 2) Preparation of kneaded powder

[0051] A. According to the design requirements,...

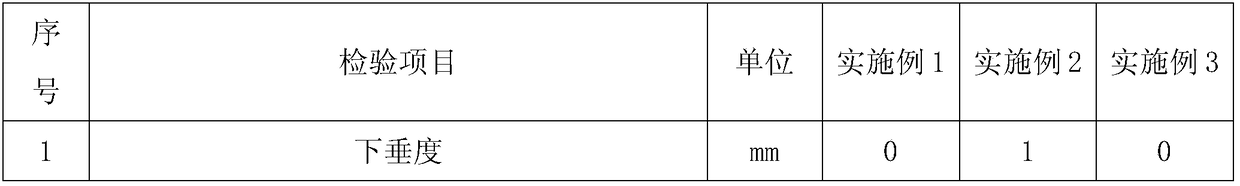

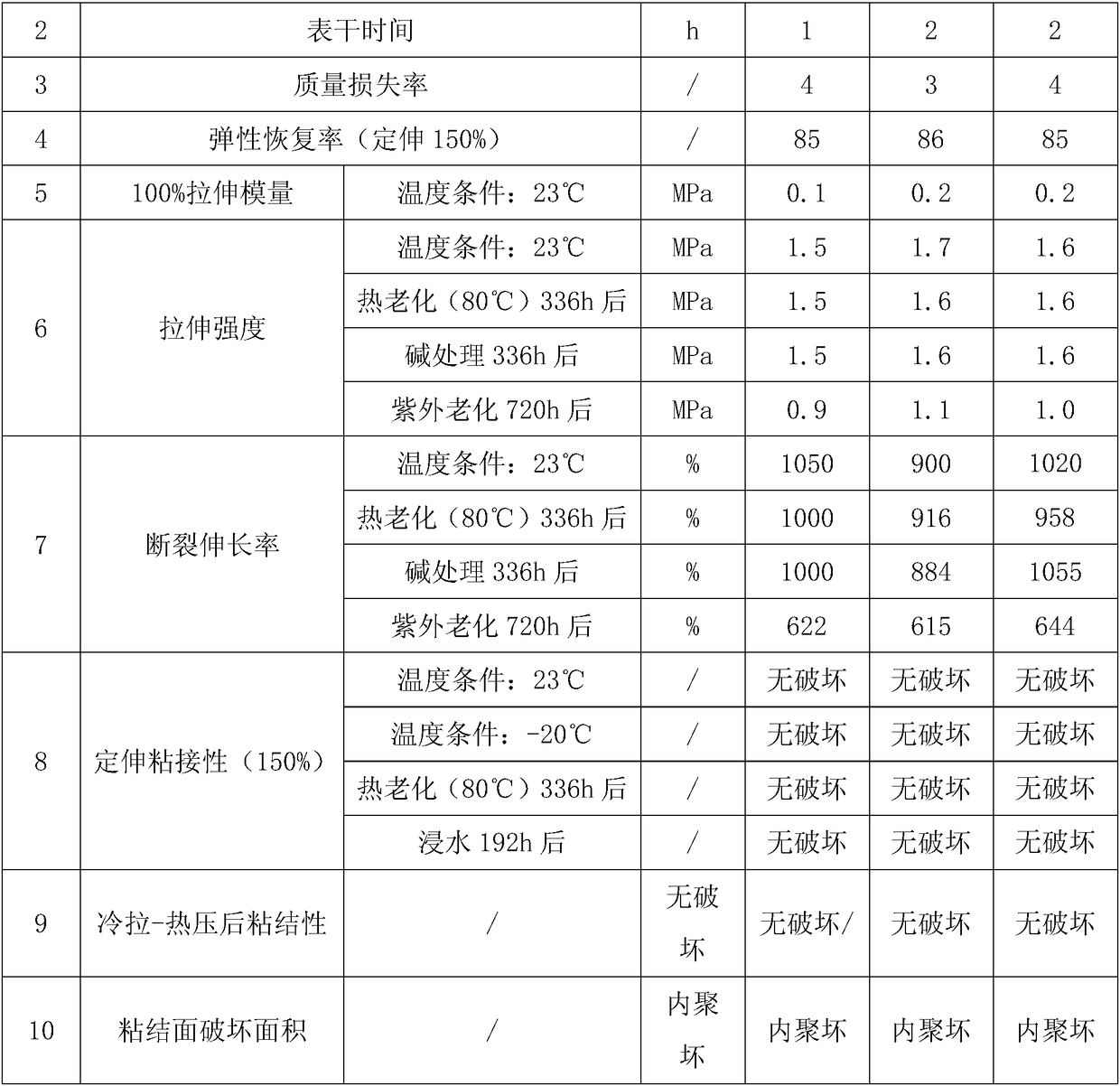

Embodiment 1

[0059] Example 1: the isocyanate-terminated prepolymer: 15 parts; plasticizer: 20 parts; special carbon black: 0.01 part; nano calcium carbonate: 40 parts; modified calcium carbonate powder: 1 part; coupling agent: 0.1 part; organic tin catalyst: 0.01 part; dispersant: 0.1 part; solvent: 1 part; water remover: 1 part; defoamer: 0.1 part; amine catalyst: 0.1 part.

Embodiment 2

[0060] Embodiment 2: The isocyanate-terminated prepolymer of the caulking and sealing material is 17.5 parts, the plasticizer is 22.5 parts, the special carbon black is 0.03 parts, the nano-calcium carbonate is 50 parts, and the modified calcium carbonate part is 3 parts , 0.3 parts of coupling agent, 0.03 parts of organic tin catalyst, 0.3 parts of dispersant, 3 parts of solvent, 3 parts of dewatering agent, 0.3 parts of defoamer, and 0.3 parts of amine catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com