A method for extracting coal-based oil residue

A technology of oil and coal production, which is applied in the direction of processing tar pitch/petroleum pitch/natural pitch by distillation, and processing tar pitch/petroleum pitch/natural pitch by selective extraction, which can solve the problem of asphalt TI, high ash content, and washing oil consumption Large and other problems, to achieve the effect of low preparation ratio, high solubility, and ash content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

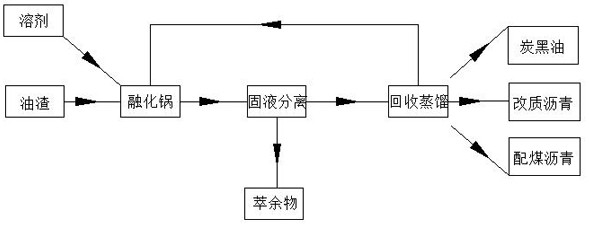

Image

Examples

Embodiment 1

[0018] Weigh 100 g of coal-based oil residue, mix the coal-based oil residue and the extractant at 160° C. for 1 hour according to a mass ratio of 1:2, and stir for 1 hour to obtain a mixed sample; the extraction agent has a distillation range of 180-240 ℃, density 0.9g / cm 3 , an aromatic hydrocarbon mixture containing 95% trimethylbenzene by mass fraction.

[0019] The mixed sample is separated; the clear liquid is distilled; after distillation, the still liquid is analyzed and tested.

[0020] See Table 2 for the asphalt performance indicators obtained after treating a certain oil residue with the extractant of the present invention.

[0021] Table 2 The performance index of asphalt obtained in the present invention

[0022] project TI% QI% Ash% asphalt 21.34 4.21 0.66

Embodiment 2

[0024] Weigh 100g of coal-based oil residue, mix the coal-based oil residue and the extractant at 170°C for 1 hour according to the mass ratio of 1:1.8, and stir for 1 hour to obtain a mixed sample; the extraction agent has a distillation range of 180-240 ℃, density 0.9g / cm 3 , an aromatic hydrocarbon mixture containing 80% trimethylbenzene by mass fraction.

[0025] The mixed sample is separated; the clear liquid is distilled; after distillation, the still liquid is analyzed and tested.

[0026] See Table 3 for the asphalt performance indicators obtained after treating a certain oil residue with the extractant of the present invention.

[0027] Table 3 Performance indicators of asphalt obtained in the present invention

[0028] project TI% QI% Ash% asphalt 20.95 4.17 0.67

Embodiment 3

[0030] Weigh 100g of coal-based oil residue, mix the coal-based oil residue and the extractant at 180°C for 1 hour according to a mass ratio of 1:1.5, and stir for 1 hour to obtain a mixed sample; the extractant is a distillation range of 180-240 ℃, density 0.9g / cm 3 , an aromatic hydrocarbon mixture containing 85% trimethylbenzene by mass fraction.

[0031] The mixed sample is separated; the clear liquid is distilled; after distillation, the still liquid is analyzed and tested.

[0032] See Table 4 for the asphalt performance indicators obtained after treating a certain oil residue with the extractant of the present invention.

[0033] Table 4 The performance index of asphalt obtained in the present invention

[0034] project TI% QI% Ash% asphalt 20.82 4.09 0.68

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com