Ultrathin EMI-resistant thin film and preparation method thereof

An ultra-thin, thin-film technology used in electrical components, magnetic/electric field shielding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

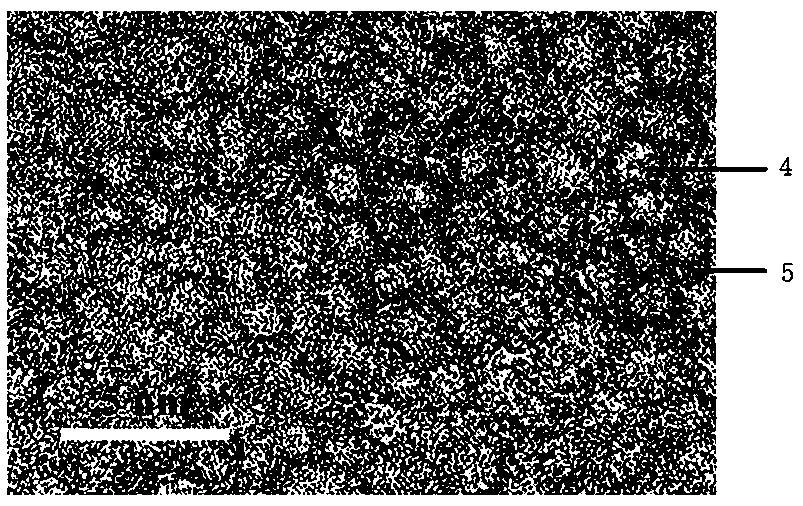

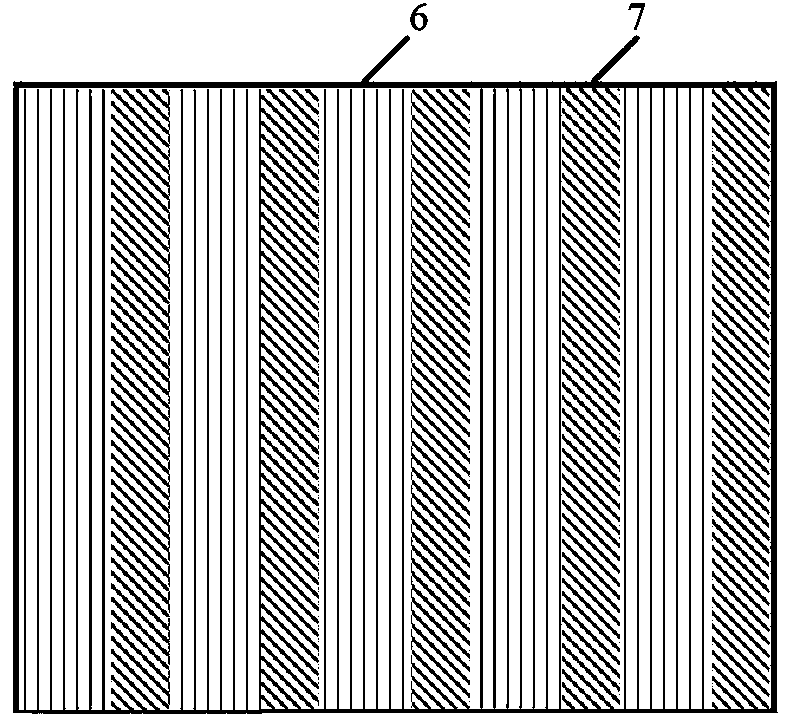

[0036] 4μm PET is used as the substrate, and a 0.05μm Ag layer is deposited on the substrate by vacuum evaporation as a metal reflective layer; (FeCo) 0.8 Al 0.2 The alloy is used as the target material, and at room temperature, the sub-layers of 0.5 μm are deposited by magnetron sputtering in the oxygen fraction of 0.02, 0.04, 0.06, 0.08, 0.10, 0.15, 0.4, 0.8, and 1.2 mtorr, in which the volume fraction of FeCo particles is determined by from 85% to 25%.

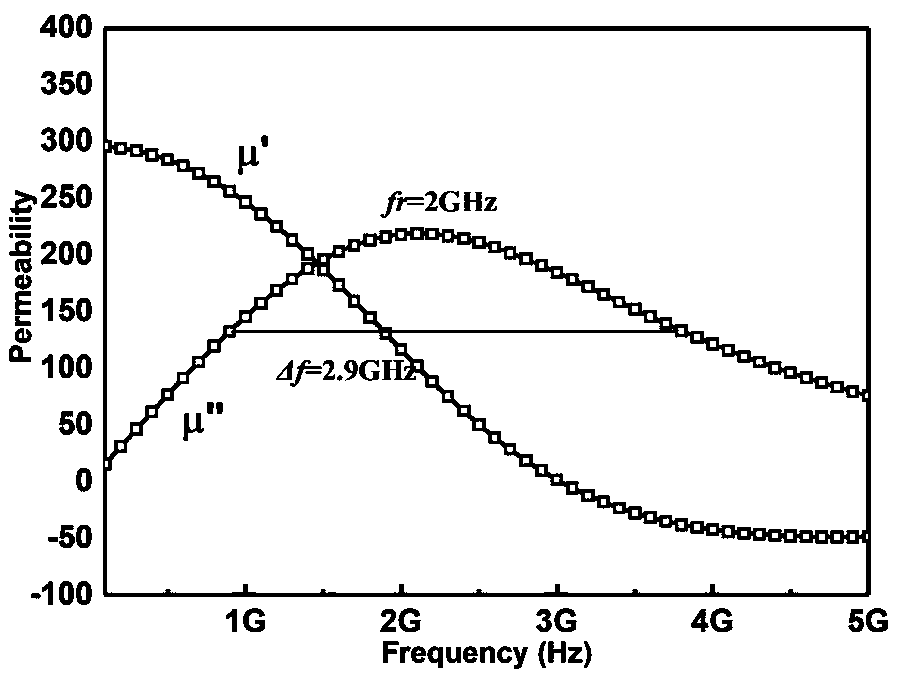

[0037] Carry out magnetic performance test on it, the magnetic permeability is 300, the cut-off frequency is 2GHz, Δf 2.9GHz.

Embodiment 2

[0039] Using 10μm copper foil as the substrate, using electroless plating to prepare a 0.1μm Ni layer on the substrate as the metal reflective layer; using Fe and SiO 2 Composite target material, using magnetron sputtering to sequentially deposit composite sublayers with Fe particle volume fractions of 95%, 90%, 80%, 70%, 60%, 50%, 40%, and 30%.

[0040] It is tested for its magnetic performance, the magnetic permeability is 240, and the cut-off frequency is 1.5GHz. Δf 1.8GHz.

Embodiment 3

[0042] Using 6μm PI as the substrate, using electron beam deposition to evaporate a 2μm Cu layer on the substrate as a metal reflective layer; using PrCo 5 and Al 2 o 3 As a composite target, a 1 μm first composite sublayer was deposited by magnetron sputtering at room temperature, where PrCo 5 Particle volume fraction is 80%; using (FeCo) 0.7 Al 0.3 Alloy as the target material, at room temperature, in 0.6mtorr oxygen concentration, magnetron sputtering deposits 0.5μm second composite sublayer, in which the volume fraction of FeCo is 68%; 0.6 Al 0.4 , at room temperature, in 0.8mtorr oxygen, magnetron sputtering deposits a 0.5μm third composite sublayer, in which the volume fraction of Fe is 48%; using Fe 0.4 Al 0.6 , at room temperature, in 1mtorr oxygen gas, magnetron sputtering deposited a 0.5μm fourth composite sublayer, in which the volume fraction of Fe was 28%;

[0043] Carry out magnetic performance test on it, the magnetic permeability is 180, the cut-off freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com