A kind of light-weight hollow carbon cube wave absorbing material and preparation method thereof

A technology of wave-absorbing materials and cubes, which is applied in the field of light-weight hollow carbon cube wave-absorbing materials and its preparation, can solve the problems of non-adjustable electromagnetic wave absorption frequency band and mismatching impedance of pure carbon wave-absorbing materials, so as to improve the absorption effect and improve The effect of absorbing frequency band and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

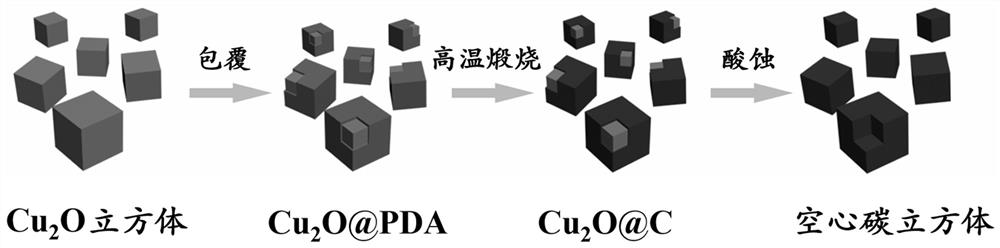

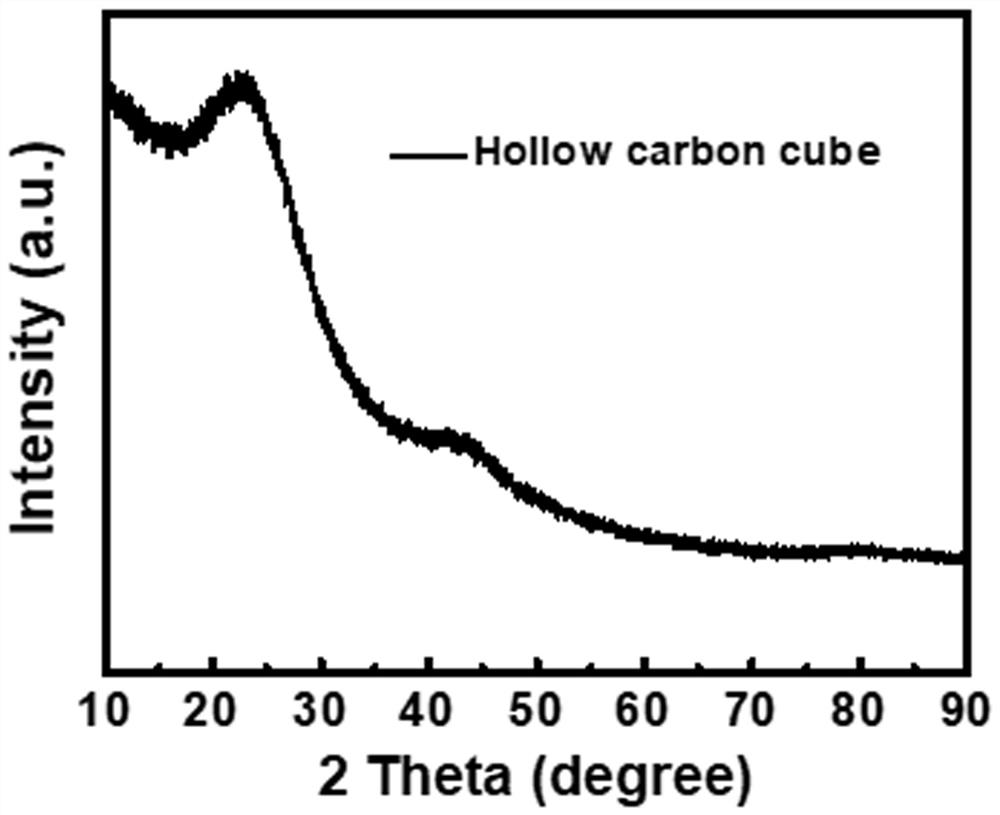

[0029] The preparation method of a light-weight hollow carbon cube wave-absorbing material of this embodiment is carried out according to the following steps:

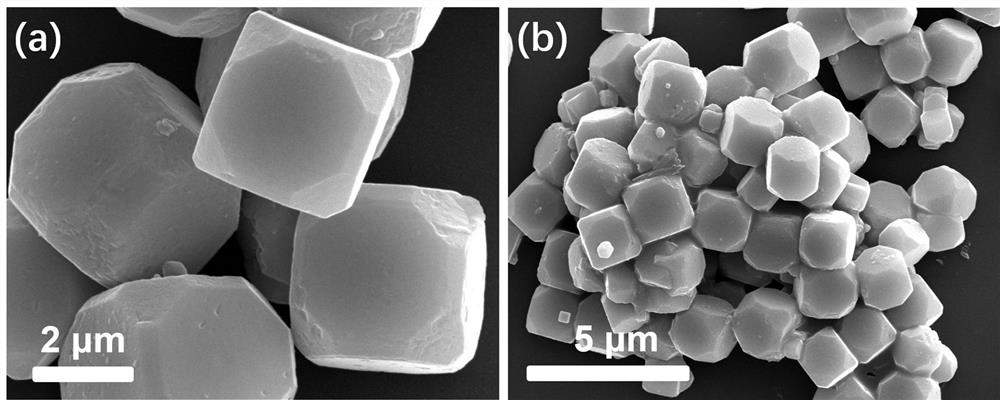

[0030] 1. Preparation of Cu 2 O cube: Cu 2 O cube is obtained by liquid phase chemical reduction method, the specific steps are: 0.02 gCu(Ac) 2 ·H 2 O was stirred and dissolved in 10 mL of deionized water, and then 0.5 g of polyethylene glycol (PEG, MW: 2000) was added and stirred for 10 min. After PEG was completely dissolved, 50 μL of NaOH solution (6.0 mol / L) was added dropwise to the mixed solution, and the mixed solution turned blue, indicating that Cu(OH) 2 Precursors are formed. After the reaction was stirred for 10 min, 0.2 mL of ascorbic acid solution (1 mol / L) was added dropwise to the reaction system. The reaction lasted for 1 h, and the solution gradually turned orange. The obtained precipitate was fully washed with deionized water and ethanol to remove PEG molecules adsorbed on the surface of the mate...

Embodiment 2

[0040] The preparation method of a light-weight hollow carbon cube wave-absorbing material of this embodiment is carried out according to the following steps:

[0041] 1. Preparation of Cu 2 O cube: Cu 2 O cubes were obtained by liquid-phase chemical reduction method, the specific steps were: 0.1 gCuSO 4 Stir to dissolve in 10 mL of deionized water, then add 5 g of polyvinylpyrrolidone and stir for 10 min. After the polyvinylpyrrolidone was completely dissolved, 50 μL of NaOH solution (6.0 mol / L) was added dropwise to the mixed solution, and the mixed solution turned blue, indicating that Cu(OH) 2 Precursors are formed. After the reaction was stirred for 10 min, 0.2 mL of ascorbic acid solution (1 mol / L) was added dropwise to the reaction system. The reaction lasted for 1 h, and the solution gradually turned orange. The obtained precipitate was fully washed with deionized water and ethanol to remove polyvinylpyrrolidone molecules adsorbed on the surface of the material, a...

Embodiment 3

[0045] The preparation method of a light-weight hollow carbon cube wave-absorbing material of this embodiment is carried out according to the following steps:

[0046] 1. Preparation of Cu 2 O cube: Cu 2 O cubes were obtained by liquid-phase chemical reduction method, the specific steps were: 0.05 gCu(NO 3 ) 2 Stir to dissolve in 10 mL of deionized water, then add 5 g of sodium dodecylbenzenesulfonate and stir for 10 min. After sodium dodecylbenzenesulfonate was completely dissolved, 50 μL of NaOH solution (8.0 mol / L) was added dropwise to the mixed solution, and the mixed solution turned blue, indicating that Cu(OH) 2 Precursors are formed. After the reaction was stirred for 10 min, 0.2 mL of ascorbic acid solution (1 mol / L) was added dropwise to the reaction system. The reaction continued for 4 h, and the solution gradually turned orange. The obtained precipitate was fully washed with deionized water and ethanol to remove the sodium dodecylbenzenesulfonate molecules ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com