A sorting method and system for baddeleyite

A kind of baddeleyite zircon and sorting technology, which is applied in the field of baddeleyite zircon sorting methods and systems, and can solve the problems of inability to obtain minerals and poor sorting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

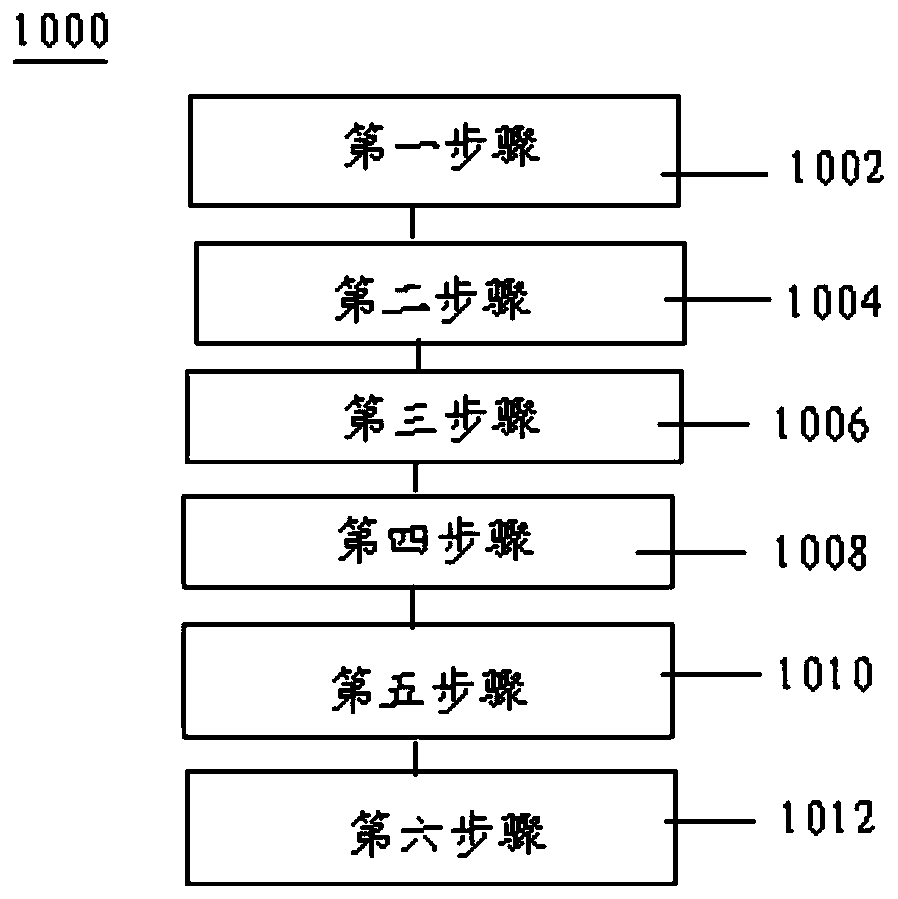

Method used

Image

Examples

Embodiment 1

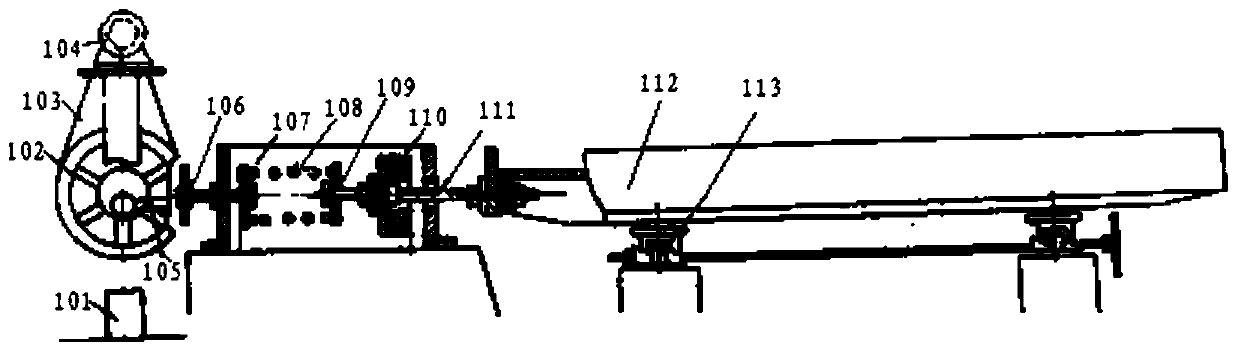

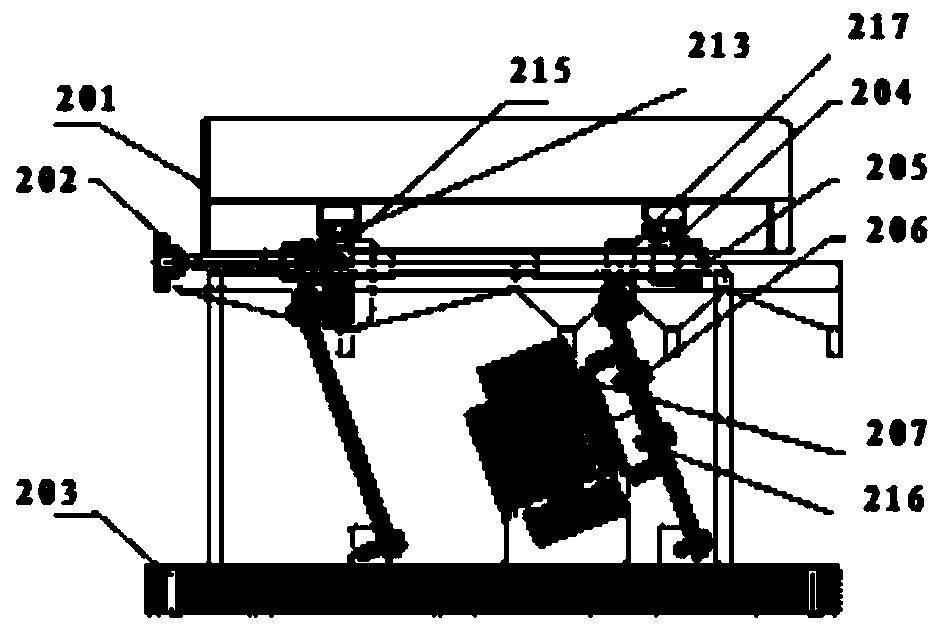

[0099] Crushing and sieving a gabbro, and then preliminarily enriching the single sample of 250 mesh to 450 mesh with a mechanical shaker. The stroke of the mechanical shaker is 10mm, the stroke frequency is 420 times / min, It is 11°, and the water volume is 6 liters / min. The heavy minerals obtained after preliminary enrichment are then subjected to magnetic separation with a strong magnetic magnet, and heavy liquid separation with DIM heavy liquid. The heavy minerals obtained are monomer samples after heavy liquid separation. Then, use an electromagnetic shaker for preliminary selection. The stroke of the electromagnetic shaker is 4mm, the number of strokes is 3000, the lateral inclination is 3°, and the water volume is 1 liter / min. After preliminary selection, baddeleyite is obtained. The purity is 51% and the final re-use concentration is 50% HNO 3 Chemical dissolution was carried out to obtain baddeleyite with a purity of 62%.

Embodiment 2

[0101] A carbonatite is crushed and sieved, and then the single sample of 250 mesh to 450 mesh is preliminarily enriched with a mechanical shaker. The stroke of the mechanical shaker is 12mm, the stroke frequency is 380 times / min, and the inclination angle is 9°, the water volume is 8.5 l / min. The heavy minerals obtained after preliminary enrichment are then subjected to magnetic separation with a strong magnetic magnet, and heavy liquid separation with DIM heavy liquid. The heavy minerals obtained are monomer samples after heavy liquid separation. Then, use an electromagnetic shaker for preliminary selection. The stroke of the electromagnetic shaker is 3mm, the number of strokes is 3000, the lateral inclination is 6°, and the water volume is 1 liter / min. After preliminary selection, baddeleyite is obtained. The purity is 53%. Finally, the concentration of 50% HNO 3 Chemical dissolution was carried out to obtain baddeleyite with a purity of 60%.

[0102]According to the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com