Dehydration treatment device of medical waste

A technology of medical waste and treatment equipment, which is applied in the field of medical waste dehydration treatment equipment, can solve problems such as environmental pollution, epidemic disease, and troublesome treatment of medical solid-liquid mixed waste, and achieve the effect of facilitating subsequent treatment and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

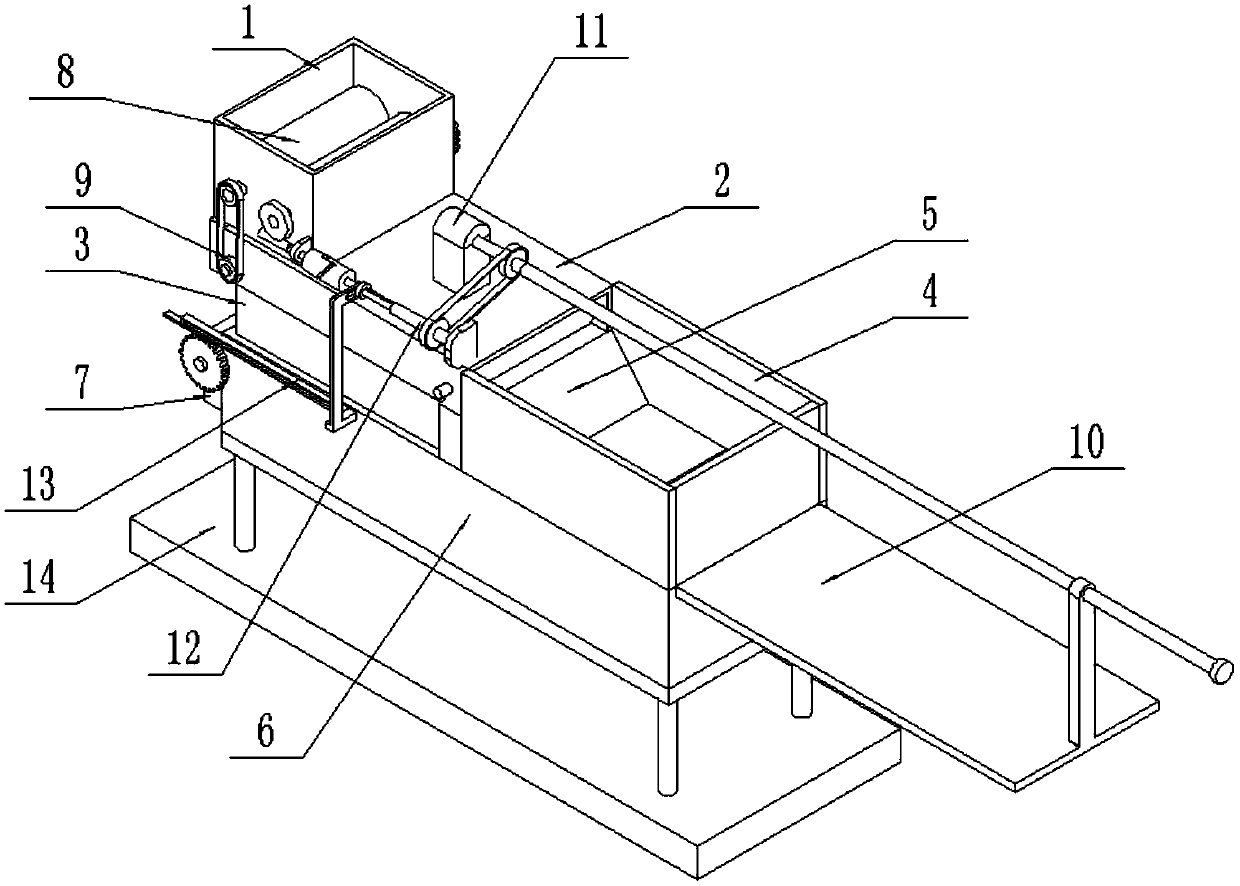

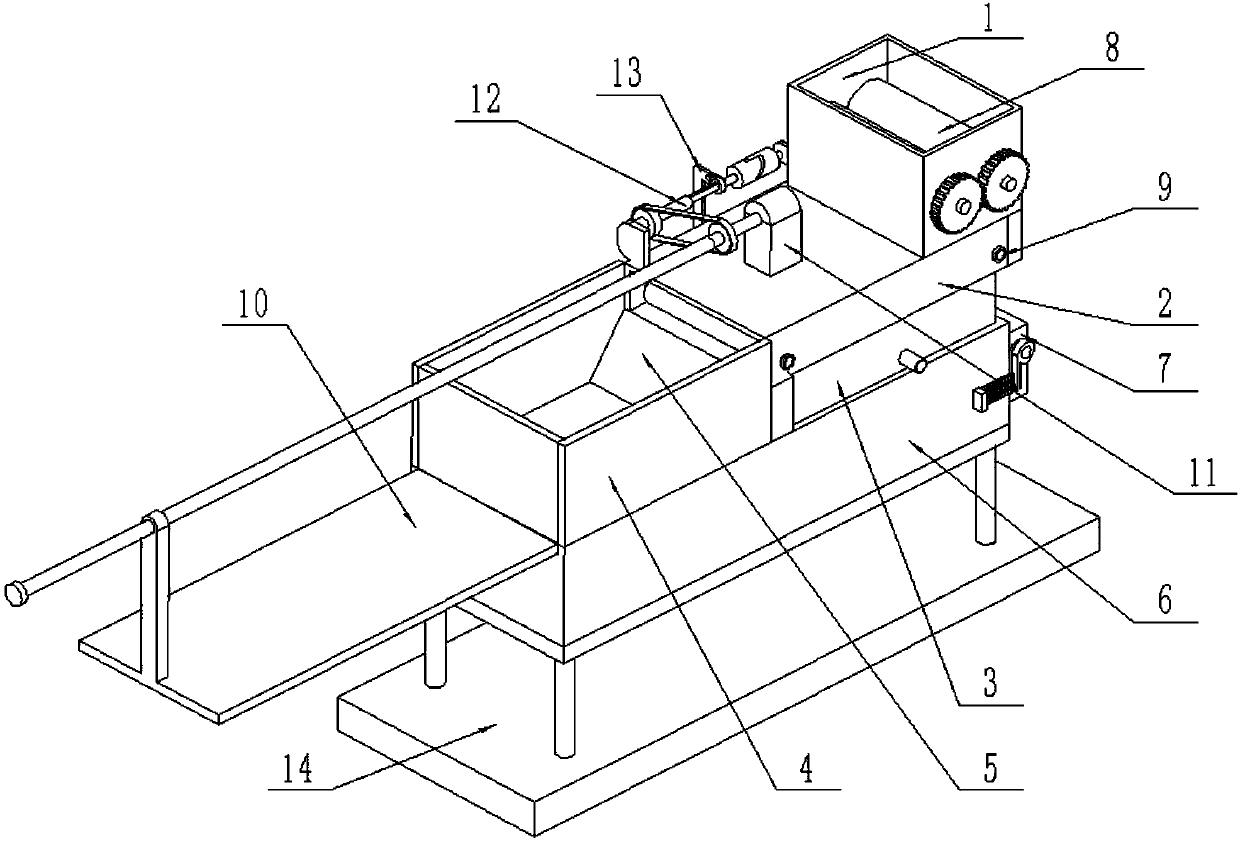

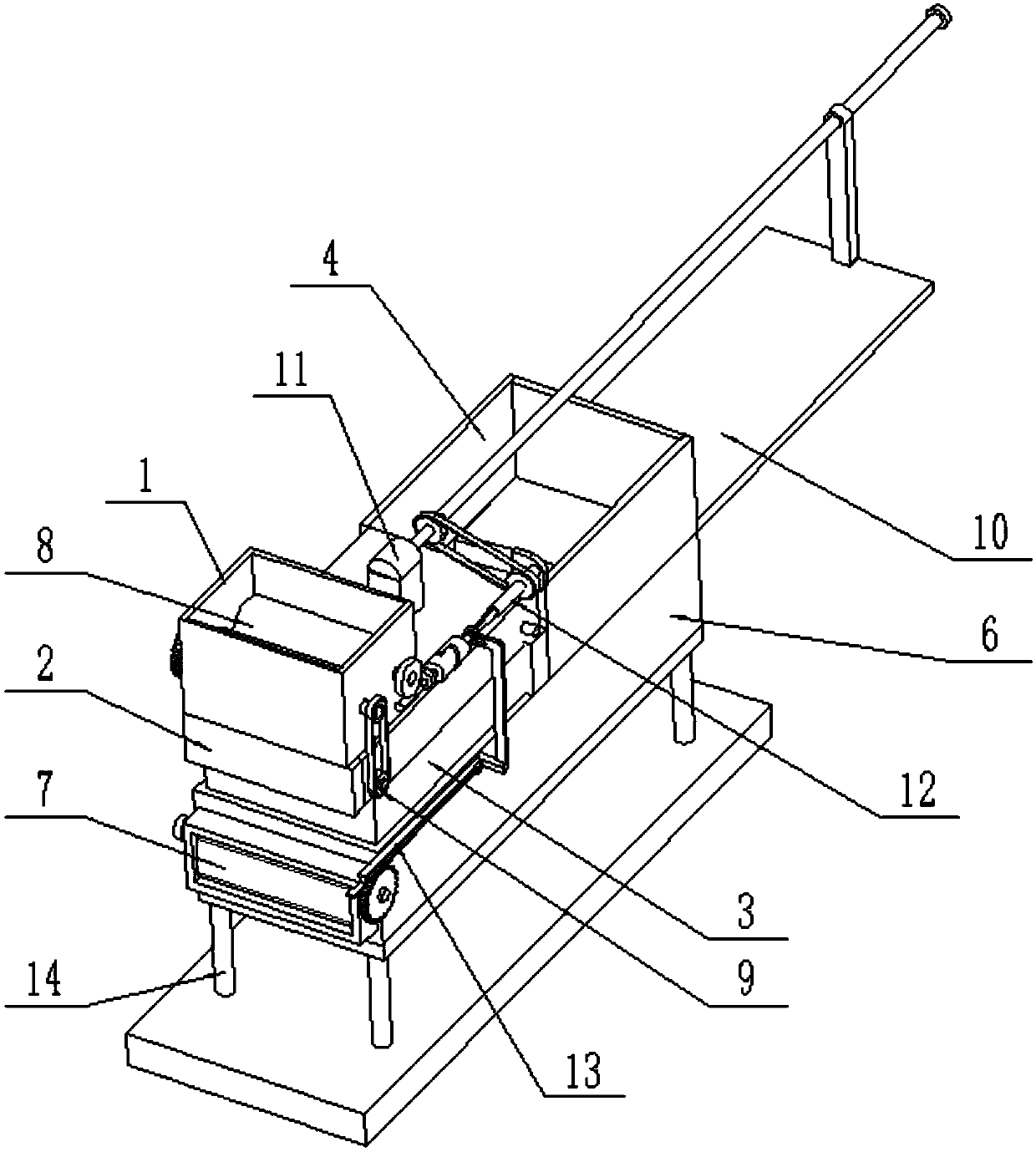

[0043] Such as Figure 1-17 As shown, a medical waste dehydration treatment device includes a waste drop box 1, a waste delivery box 2, a sewage collection box 3, a blanking box 4, a scraping plate 5, a squeeze dehydration box 6, and a discharge door assembly 7 , a waste pretreatment device 8, a waste conveying and dehydrating device 9, a waste squeezing and dehydrating device 10, a drive control device 11, a drive wheel assembly 12, a feed control assembly 13 and a support frame 14, and the waste drop box 1 The lower end is fixedly connected and connected to the waste delivery box 2; the bottom surface of the waste delivery box 2 is provided with a drain hole, the top surface of the sewage collection box 3 is hollowed out, and the sewage collection box 3 is fixedly connected to the waste delivery box 2 The lower end of the sewage collection box 3 communicates with the waste delivery box 2 through the drain hole; the rear end of the waste delivery box 2 is fixedly connected an...

specific Embodiment approach 2

[0046] Such as Figure 1-17 As shown, the drive control device 11 includes a drive motor 11-1, a drive shaft 11-2 and a drive pulley 11-3; the output shaft of the drive motor 11-1 is connected to the drive shaft 11-2 through a coupling; The driving shaft 11-2 is fixedly connected to the driving pulley 11-3; the driving motor 11-1 is fixedly connected to the waste transport box 2 through the motor base; The material extrusion dehydration device 10; the drive pulley 11-3 is connected to the drive wheel assembly 12 through a belt. When the drive control device 11 is in use, after the drive motor 11-1 is connected to the power supply and turned on by the control switch, the drive motor 11-1 can drive the drive shaft 11-2 to rotate, and the drive shaft 11-2 can drive the drive shaft 11-2 when it rotates. The pulley 11-3 rotates, the drive pulley 11-3 can drive the transmission wheel assembly 12 to work, and the waste extrusion dehydration device 10 can work when the drive shaft 11...

specific Embodiment approach 3

[0047] Such as Figure 1-17 As shown, the waste squeezing and dehydrating device 10 includes an externally threaded transmission shaft 10-1, a limit plate 10-2, a movable connecting plate 10-3, a falling blocking plate 10-4 and an extruding plate 10-5; One end of the externally threaded transmission shaft 10-1 is connected to the drive shaft 11-2 through a coupling, and the other end of the externally threaded transmission shaft 10-1 is threaded to the limit disc 10-2; the movable connecting plate 10-3 One end is screwed to the externally threaded transmission shaft 10-1, and the other end of the movable connecting plate 10-3 is fixedly connected to the rear end of the falling-blocking plate 10-4; On the rear side of the case 6, the front end of the falling plate 10-4 is fixedly connected to the extruding plate 10-5, and the extruding plate 10-5 is slidingly fitted and connected to the inner surface of the extruding and dehydrating case 6. When the waste extrusion dehydration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com