Environmental-friendly cellulose-based flame-retardant thermal insulation material and preparation method thereof

A cellulose-based, heat-insulating material technology is applied in the field of cellulose-based flame-retardant and heat-insulating materials, environment-friendly cellulose-based flame-retardant heat-insulating materials and their preparation fields, and can solve the problems of restricting cellulose materials, complicated preparation process and easy generation. Smoke and other problems, to achieve the effect of reducing the amount of smoke released, the process flow is short, and the processing process flow is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

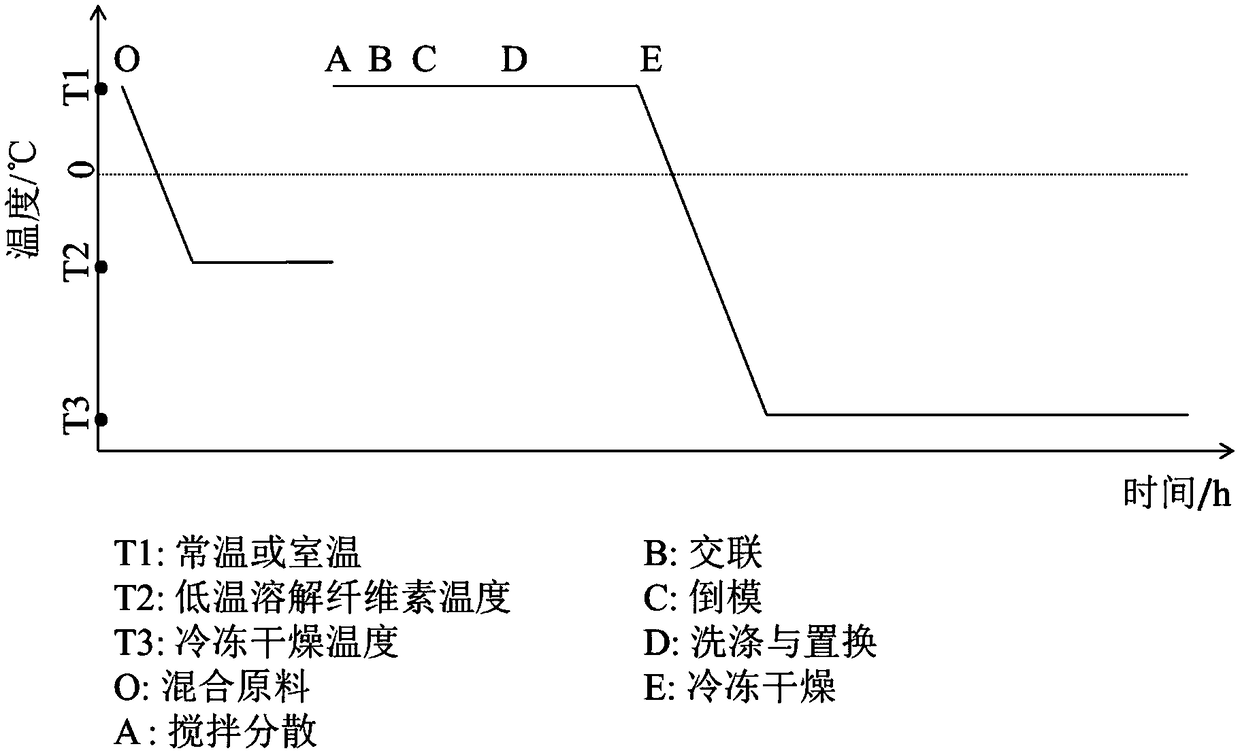

[0034] A preparation method of an environmentally friendly cellulose-based flame-retardant heat-insulating material, such as figure 1 As shown, the specific steps are as follows:

[0035] (1). Take several portions of thick cotton pulp containing 3g of cotton, and weigh 0.6g of Mg / Al(OH)-LDHs, Mg / Al(CO 3 )-LDHs, Mg / Al(PO 4 )-LDHs, Mg / Al(HPO 4 )-LDHs, Mg / Al(H 2 PO 4 )-LDHs, Mg / Al(NO 3 )-LDHs, Mg / Al(B 4 o 7 )-LDHs and put into cotton pulp, then gradually add NaOH 7g and water, after NaOH dissolves and the solution is cooled, add urea 12g, finally control the NaOH concentration to be 7wt%, the urea concentration to be 12wt%, and the cellulose mass to be 3wt% , the total mass of the mixture was 100.6 g, stirred and dissolved, and then frozen at -20°C for 2 hours.

[0036] (2). Take out the frozen mixture in step (1) and stir it with 200r / min until the cotton fiber is completely dissolved and the layered double metal hydroxide is evenly dispersed to obtain the LDHs / cellulos...

Embodiment 2

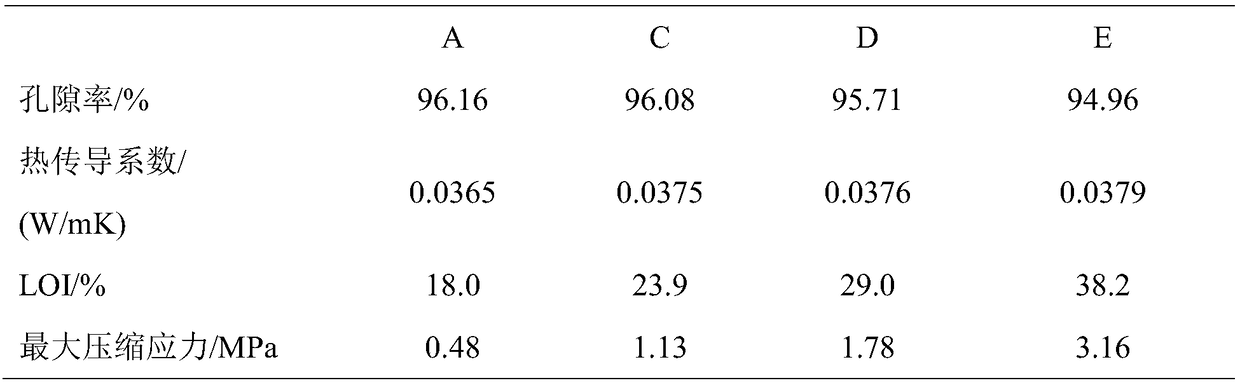

[0044] A preparation method of an environmentally friendly cellulose-based flame-retardant heat-insulating material, the specific steps are as follows:

[0045] (1). Take five parts of 4g and obtain broken cotton after waste cotton fabric treatment, weigh 0.4g, 1.6g, 4.0gMg / Al(CO 3 )-LDHs, after mixing the components, add 96g of alkaline urine solution to make each component completely wet, and then freeze at -20°C for 1.5h. The alkaline urine solution contains 7 wt% of NaOH, 12 wt% of urea and 81 wt% of water.

[0046] (2). Take out the frozen mixture in step (1) and add high-speed stirring until the chopped cotton fibers are completely dissolved and the layered double metal hydroxide is evenly dispersed to obtain a mixed solution of LDHs / cellulose.

[0047] (3). Add 1.2g of N,N-methylenebisacrylamide to several groups of solutions obtained in step (2), stir at high speed for 30 minutes, then ultrasonically disperse for 5 minutes, then continue stirring at high speed for 30 ...

Embodiment 3

[0055] A preparation method of an environmentally friendly cellulose-based flame-retardant heat-insulating material, the specific steps are as follows:

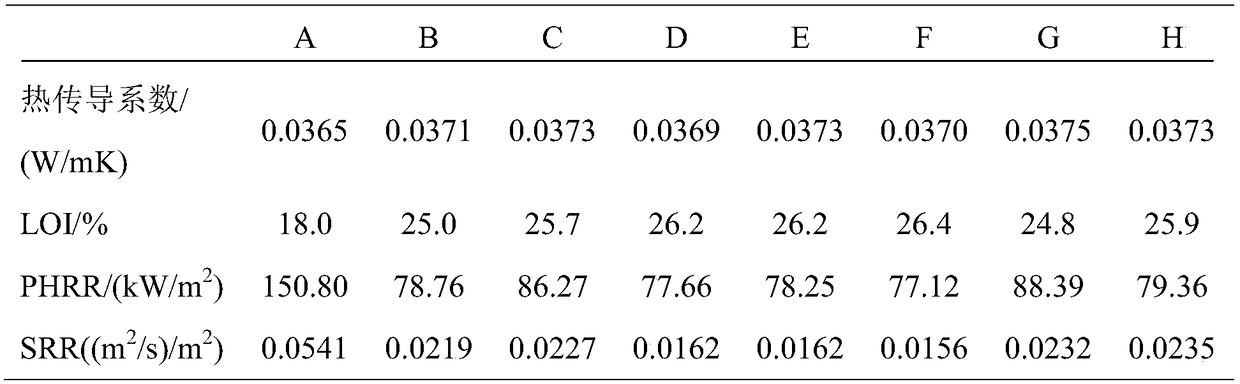

[0056] (1). Take several pieces of cotton containing about 7g of cellulose, 93g of alkali urine solution and layered double metal hydroxide, stir to make each component soak and freeze at -20°C for 3 hours, and the layered bimetal The hydroxide content is respectively:

[0057] A:0g

[0058] B:Ca / Al(CO 3 )-LDHs 1.2g

[0059] C:Mg / Al(CO 3 )-LDHs 1.2g

[0060] D:Mg / Al(H 2 PO 4 )-LDHs 1.2g

[0061] E:Ca / Al(CO 3 )-LDHs 0.6g, Mg / Al(CO 3 )-LDHs 0.6g

[0062] F:Mg / Al(H 2 PO 4 )-LDHs 0.6g, Mg / Al(CO 3 )-LDHs 0.6g

[0063] G:Ca / Al(CO 3 )-LDHs 0.6g, Mg / Al(H 2 PO 4 )-LDHs 0.6g; the alkaline urine solution contains 7wt% NaOH, 12wt% urea and 81wt% water.

[0064] (2). Take out the frozen mixture in step (1) and add high-speed stirring until the chopped cotton fibers are completely dissolved and the layered double metal hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com