A liquid lubricant and a drilling fluid

A lubricant and drilling fluid technology, applied in the field of petroleum drilling fluid, can solve problems such as poor lubrication effect, reduced drilling safety, and reduced safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

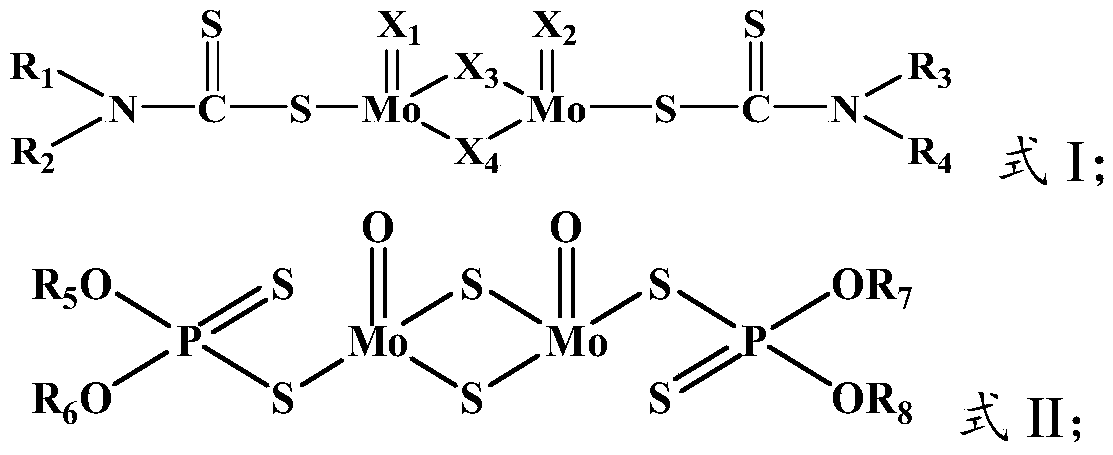

[0037] The present invention has no special requirements on the preparation method of the liquid lubricant, and the preparation method of the composition well known to those skilled in the art can be adopted. In the present invention, the preparation method of the liquid lubricant preferably includes: mixing the base oil, surfactant, carbon black and organic molybdenum compound to obtain the liquid lubricant. The present invention has no special requirements on the specific implementation of the mixing, and a mixing method well known to those skilled in the art can be used. In the present invention, the mixing temperature is preferably 50-60°C, more preferably 52-55°C; the mixing time is preferably 1-1.5h. The present invention mixes the raw materials under the temperature conditions, so that the components in the liquid lubricant can be mixed at a molecular level, so that the obtained liquid lubricant has better lubricating performance.

[0038] The present invention also pr...

Embodiment 1

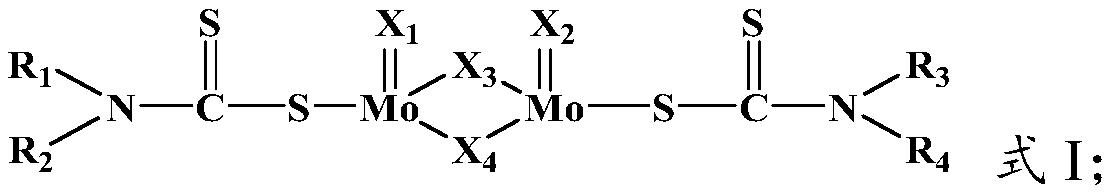

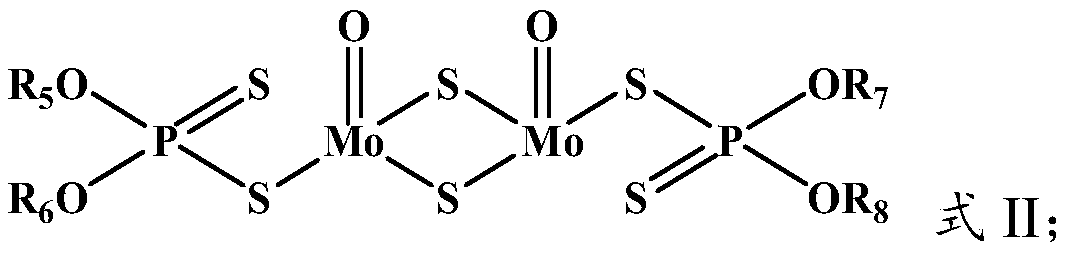

[0048] With 60g white oil, 10g sorbitan monostearate (Span 60), 10g carbon black (particle size is 50~150 microns), 8.5g MoDTC, 1.5g MoDDP (the weight ratio of MoDTC and MoDDP is 5.7: 1) Mix uniformly at 50°C to obtain liquid lubricant R1.

Embodiment 2

[0050] 75g of diesel oil, 5g of sorbitan monooleate (Span 80), 15g of carbon black (with a particle size of 50-150 microns), 9g of MoDTC, and 1g of MoDDP (that is, the weight ratio of MoDTC to MoDDP is 9:1) Mix well at 60°C to obtain liquid lubricant R2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com