Method for Improving Wear Resistance of Bearing and Bearing

A wear-resistant performance and bearing technology, which is applied in the field of vacuum coating, can solve the problems of oxidative deterioration of lubricating grease, adverse effects of lubrication system, and the need to further enhance the wear-resistant performance of bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

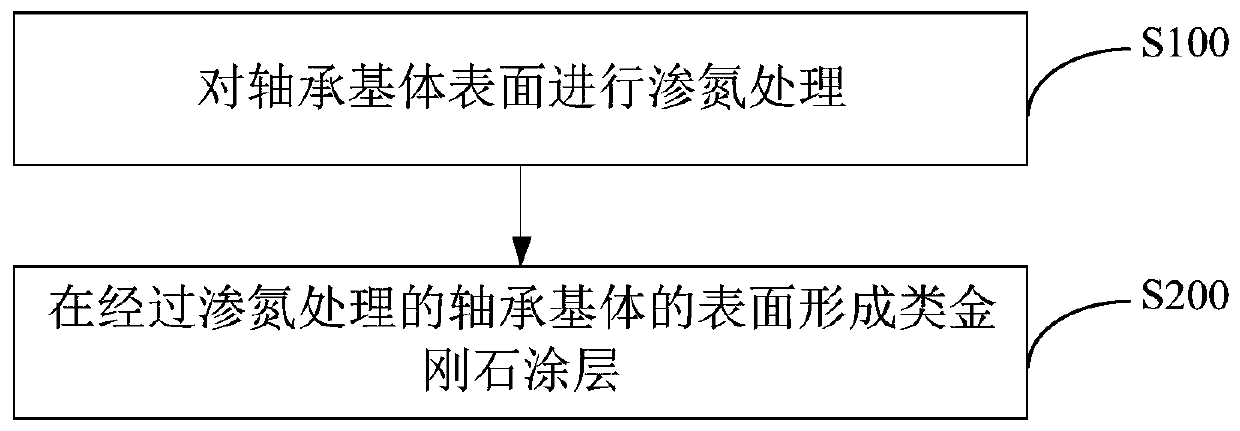

Method used

Image

Examples

Embodiment 1

[0039] Example 1: In-situ nitriding treatment on the GCr15 bearing substrate to prepare a diamond-like coating to strengthen the wear resistance of the bearing

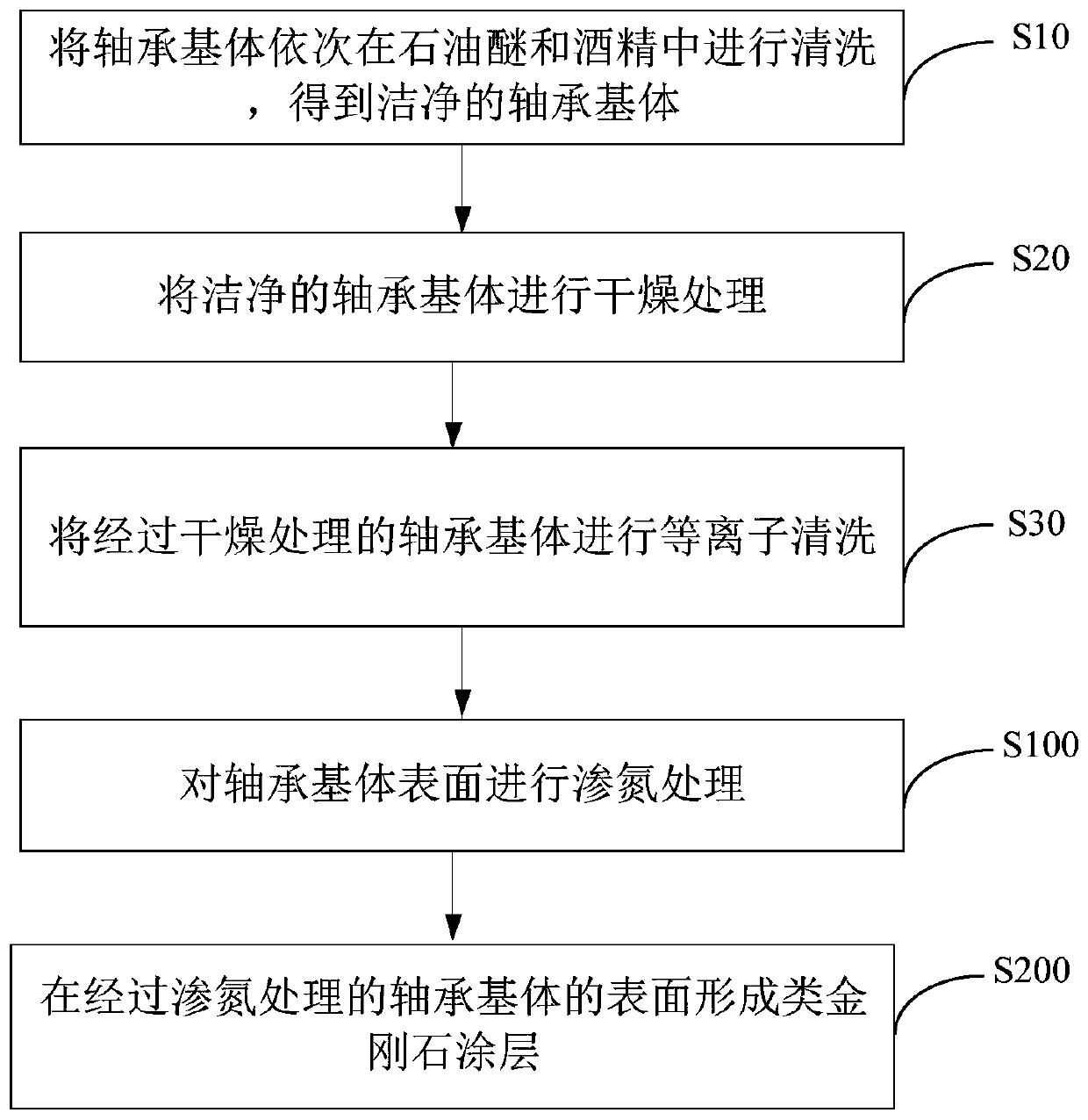

[0040] (1) The bearing base is first pre-cleaned with petroleum ether and alcohol, and put into a drying oven for drying.

[0041] (2) After the bearing matrix is placed in the cavity of the PECVD equipment, the cavity is vacuumed up to 1x10 -4 Below Pa, perform chamber plasma cleaning: the cleaning conditions are: argon protection and control at 10Pa, bias voltage 800V, conduction ratio 0.6, cleaning for 30 minutes.

[0042] (3) In-situ nitriding of the bearing substrate: PECVD equipment is used to provide a pulse bias voltage setting of -1000V, a conduction ratio of 0.8, and a frequency of 80Hz; nitrogen gas of 10Pa; nitriding for 100 minutes.

[0043] (4) Surface diamond-like deposition: use PECVD equipment, bias -1000V, conduction ratio 0.8, feed methane 20Pa, deposit coating for 150 minutes.

[0044] Through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com