Environment-friendly micro-emulsified cutting fluid and preparation method thereof

An environment-friendly, micro-emulsion technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor lubricity and anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

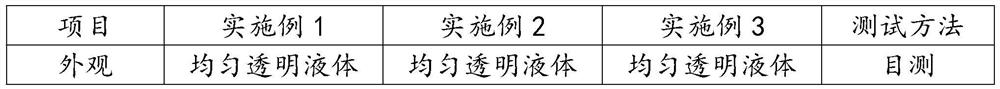

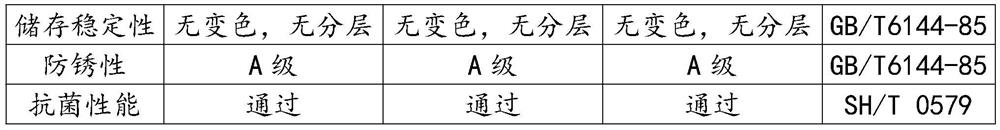

Examples

Embodiment 1

[0040] An environment-friendly microemulsion cutting fluid, comprising the following raw materials in parts by weight:

[0041] 20 parts of base oil, 3 parts of fatty alcohol polyoxyethylene ether, 40 parts of deionized water, 2 parts of tall oil acid, 1 part of water-soluble additive and 6 parts of polymer microspheres;

[0042] The preparation method of the environment-friendly microemulsion cutting fluid comprises the following steps:

[0043] In the first step, after mixing the base oil and fatty alcohol polyoxyethylene ether, the temperature is raised to 58°C, and the oil phase components are configured;

[0044] In the second step, deionized water, tall oleic acid and water-soluble additives are mixed to make water phase components;

[0045] Step 3: After mixing the water phase components and the oil phase components, the temperature was raised to 53° C., polymer microspheres were added, and stirred for 30 minutes to obtain an environment-friendly microemulsion cutting ...

Embodiment 2

[0061] An environment-friendly microemulsion cutting fluid, comprising the following raw materials in parts by weight:

[0062] 25 parts of base oil, 4 parts of fatty alcohol polyoxyethylene ether, 45 parts of deionized water, 3 parts of tall oil acid, 2 parts of water-soluble additives and 7 parts of polymer microspheres;

[0063] The preparation method of the environment-friendly microemulsion cutting fluid comprises the following steps:

[0064] In the first step, after mixing the base oil and fatty alcohol polyoxyethylene ether, the temperature is raised to 60°C, and the oil phase components are configured;

[0065] In the second step, deionized water, tall oleic acid and water-soluble additives are mixed to make water phase components;

[0066] Step 3: After mixing the water phase components and the oil phase components, the temperature was raised to 55° C., polymer microspheres were added, and stirred for 35 minutes to obtain an environment-friendly microemulsion cuttin...

Embodiment 3

[0082] An environment-friendly microemulsion cutting fluid, comprising the following raw materials in parts by weight:

[0083] 30 parts of base oil, 5 parts of fatty alcohol polyoxyethylene ether, 50 parts of deionized water, 4 parts of tall oil acid, 3 parts of water-soluble additives and 8 parts of polymer microspheres;

[0084] The preparation method of the environment-friendly microemulsion cutting fluid comprises the following steps:

[0085] In the first step, after mixing the base oil and fatty alcohol polyoxyethylene ether, the temperature is raised to 62°C, and the oil phase components are configured;

[0086] In the second step, deionized water, tall oleic acid and water-soluble additives are mixed to make water phase components;

[0087] In the third step, the water phase component and the oil phase component are mixed, and the temperature is raised to 57° C., polymer microspheres are added, and stirred for 40 minutes to obtain an environment-friendly microemulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com