A kind of tin bronze-steel bimetallic composite material and preparation method thereof

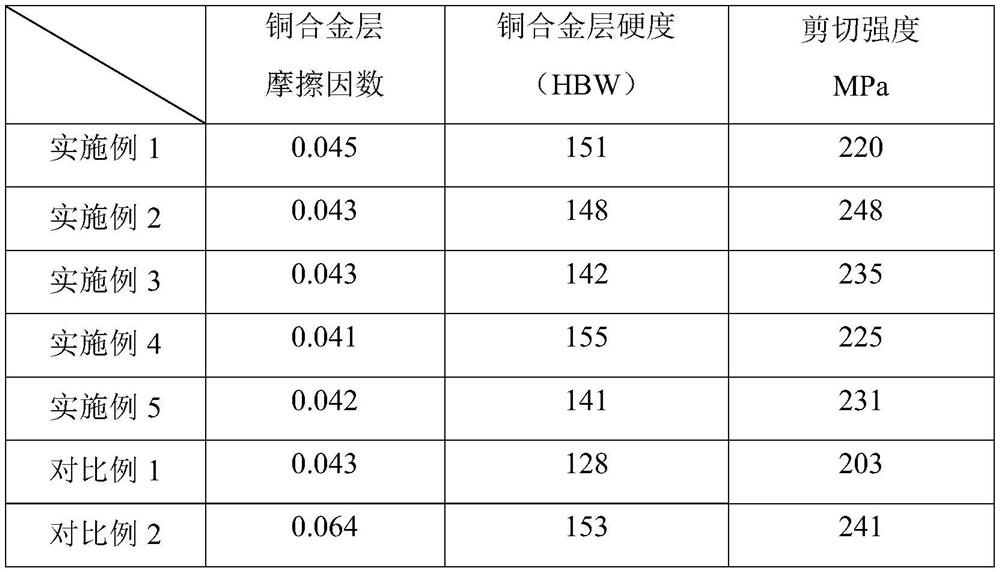

A composite material, tin bronze technology, which is applied in the field of tin bronze-steel bimetallic composite materials and its preparation, can solve the problems of difficulty in meeting the requirements of medium and high pressure hydraulic pumps, low hardness of copper alloy layer, poor interface bonding strength, etc., and achieve Improve the bonding strength of the interface, reduce equipment investment, and increase the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

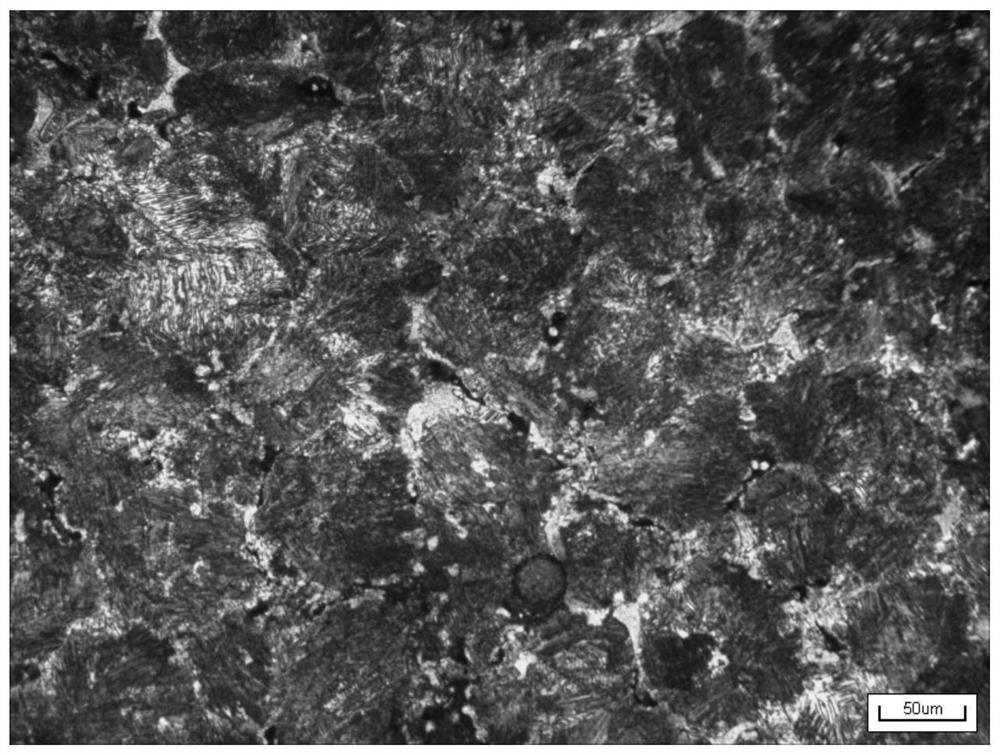

Image

Examples

Embodiment 1

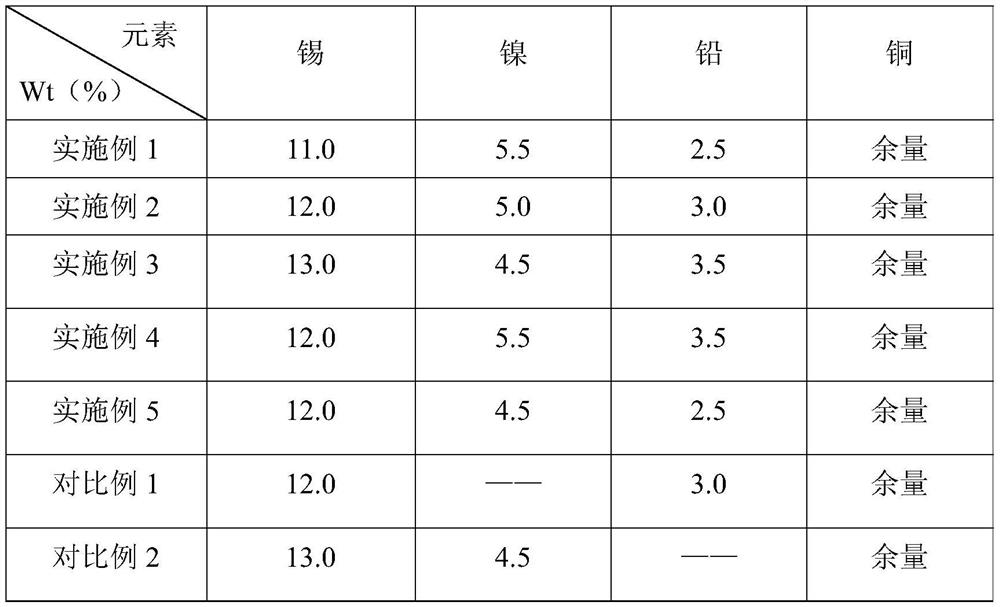

[0023] (1) Adopt atomization method to prepare alloyed tin bronze powder material, the component content of alloyed tin bronze powder material is as shown in table 1, take by weighing 100 parts of alloyed tin bronze powder material, then add 0.6 part of stearin wherein Zinc acid to obtain the mixture, put the mixture into the mixer and mix it fully, take it out, and use a mechanical press to press the mixture to obtain a green compact with a density of 8.0g / cm 3 Tin bronze powder compacts;

[0024] (2) the material of steel substrate selects 45# steel, at first steel substrate surface is cleaned, then carries out copper-plating process on its surface, forms the copper-plated layer that thickness is 0.005mm on the surface of steel substrate;

[0025] (3) The sintering atmosphere is a nitrogen-hydrogen mixture with a hydrogen content of 15%, and the copper-plated steel substrate is placed on a tin bronze powder compact, and then placed together in a sintering furnace for heating...

Embodiment 2

[0027] (1) Adopt atomization method to prepare alloyed tin bronze powder material, the component content of alloyed tin bronze powder material is as shown in table 1, take by weighing 100 parts of alloyed tin bronze powder material, then add 0.4 part of stearin wherein Zinc acid to obtain the mixture, put the mixture into the mixer and mix it fully, take it out, and use a mechanical press to press the mixture to obtain a green compact with a density of 8.2g / cm 3 Tin bronze powder compacts;

[0028] (2) the material of steel substrate selects 45# steel, at first steel substrate surface is cleaned, then carries out copper-plating process on its surface, forms the copper-plated layer that thickness is 0.010mm on the surface of steel substrate;

[0029] (3) The sintering atmosphere is a nitrogen-hydrogen mixture with a hydrogen content of 16%. The copper-plated steel substrate is placed on a tin bronze powder compact, and then placed together in a sintering furnace for heating and...

Embodiment 3

[0031] (1) Adopt atomization method to prepare alloyed tin bronze powder material, the component content of alloyed tin bronze powder material is as shown in table 1, take by weighing 100 parts of alloyed tin bronze powder material, then add 0.8 part of stearin wherein Zinc acid to obtain the mixture, put the mixture into the mixer and mix it fully, take it out, and use a mechanical press to press the mixture to obtain a green compact with a density of 7.8g / cm 3 Tin bronze powder compacts;

[0032] (2) the material of steel substrate selects 45# steel, at first steel substrate surface is cleaned, then carries out copper-plating process on its surface, forms the copper-plated layer that thickness is 0.013mm on the surface of steel substrate;

[0033] (3) The sintering atmosphere is a nitrogen-hydrogen mixture with a hydrogen content of 14%. The copper-plated steel substrate is placed on a tin bronze powder compact, and then placed together in a sintering furnace for heating and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com