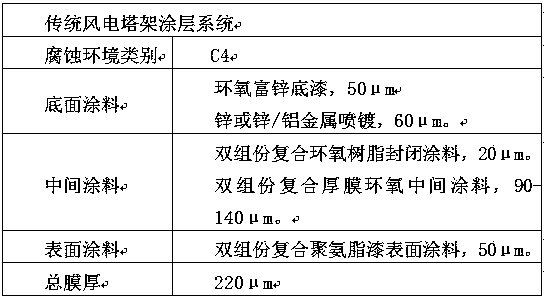

Novel environment-friendly self-healing composite coating of wind power equipment and spraying method

A technology for wind power equipment and composite coating, which is applied in the direction of coating, metal material coating process, fusion spraying, etc. low problems, to achieve the effect of excellent wear resistance, good function and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A new type of environmentally friendly self-healing composite coating for wind power equipment, including a transition layer and a working layer; the formulation of the working layer includes the following raw materials in mass percentages: C 0.1%, B 3.5%, Si 1.0%, Cr 17.0%, Fe 1.0%, MoS 2 13.0%, and the balance is Ni; the formula of the transition layer includes the following raw materials in mass percentage: Ni 70%, and the balance is Al.

[0056] The particle size of the raw material is 10-45μm.

[0057] A novel method for spraying composite coatings of environmentally friendly self-healing wind power equipment, including the following spraying steps:

[0058] S1. Pretreatment of the workpiece: use dry oil-free angular iron sand for sandblasting;

[0059] S2. Spraying the transition layer: Weigh the formula of the transition layer and fully mix it, and use the HVOF supersonic flame spraying equipment to spray the transition layer on the surface of the workpiece; t...

Embodiment 2

[0066] A new type of environmentally friendly self-healing composite coating for wind power equipment, including a transition layer and a working layer; the formulation of the working layer includes the following raw materials in mass percentages: C 1.0%, B 0.5%, Si 4.5%, Cr 10.0%, Fe 3.0%, MoS 2 8.0%, ceramic powder 3%, the balance is Ni; the formula of the transition layer includes the following raw materials in mass percentage: Ni 90%, the balance is Al.

[0067] The particle size of the raw material is 10-45μm.

[0068] The particle size of the ceramic powder is 15-40μm.

[0069] A novel method for spraying composite coatings of environmentally friendly self-healing wind power equipment, including the following spraying steps:

[0070] S1. Pretreatment of the workpiece: use dry oil-free angular iron sand for sandblasting;

[0071] S2. Spraying the transition layer: Weigh the formula of the transition layer and mix well, and use HVOF supersonic flame spraying equipment ...

Embodiment 3

[0078] A new type of environmentally friendly self-healing composite coating for wind power equipment, including a transition layer and a working layer; the formulation of the working layer includes the following raw materials in mass percentages: C 0.6%, B 2.0%, Si 2.8%, Cr 13.5%, Fe 2.0%, MoS 2 10.5%, ceramic powder 10%, the balance is Ni; the formula of the transition layer includes the following raw materials in mass percentage: Ni 80%, the balance is Al.

[0079] The particle size of the raw material is 10-45μm.

[0080] The particle size of the ceramic powder is 15-40μm.

[0081] A novel method for spraying composite coatings of environmentally friendly self-healing wind power equipment, including the following spraying steps:

[0082] S1. Pretreatment of the workpiece: use dry oil-free angular iron sand for sandblasting;

[0083] S2. Spraying the transition layer: Weigh the formula of the transition layer and mix well, and use HVOF supersonic flame spraying equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com