Dyeing device for processing soft cotton knitted fabric and fabric processing method

A technology for knitted fabrics and dyeing devices, which is applied in the directions of dyeing method, textile processing machine accessories, and equipment configuration for processing textile materials, etc., can solve problems such as affecting the smoothness and feel of cotton knitted fabrics, affecting fabric processing efficiency, and lengthening fabric processing cycles. , to achieve excellent appearance after washing, shorten the dyeing time, and improve the effect of dyeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

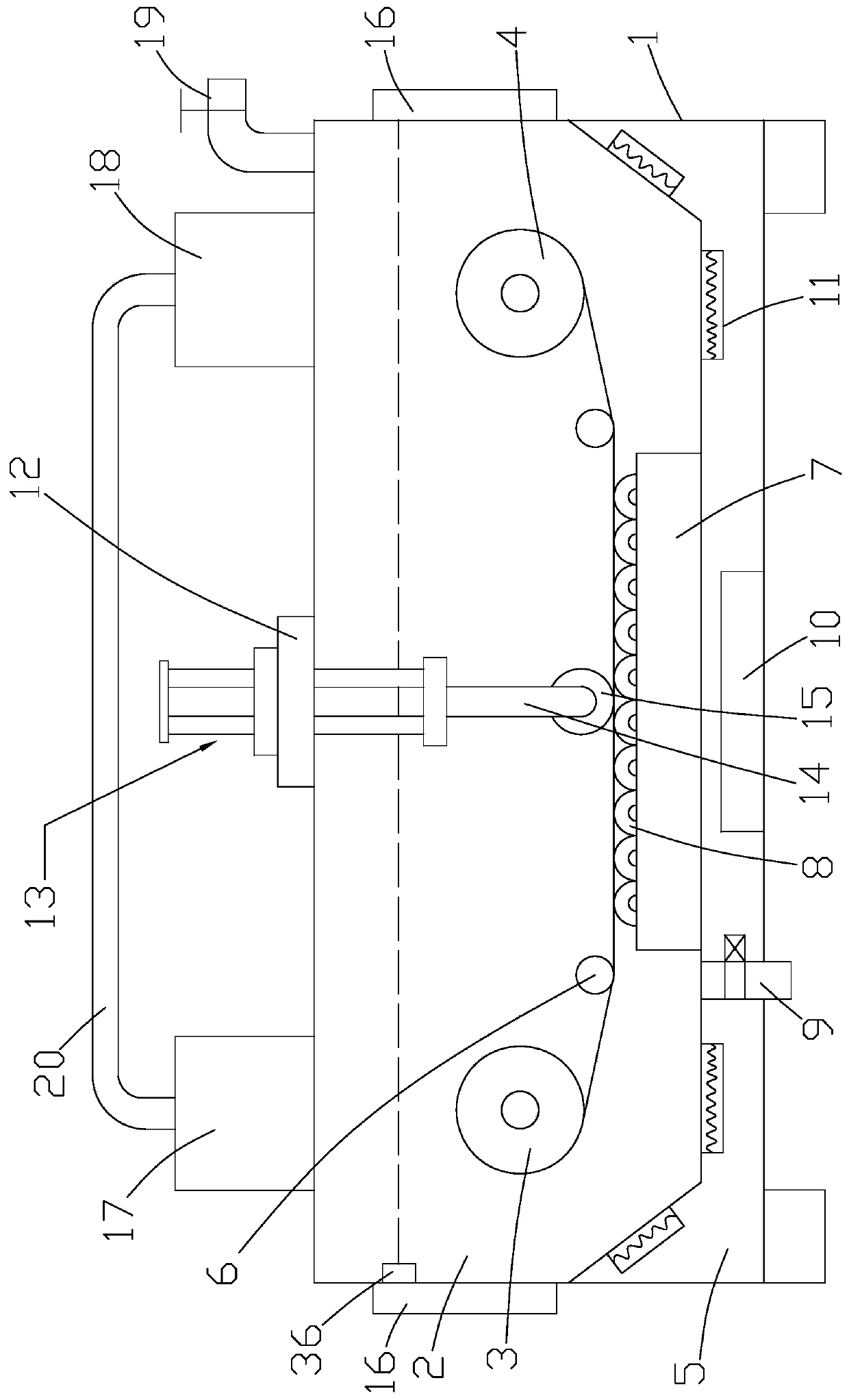

[0037] Such as Figure 1 to Figure 3 As shown, it is a dyeing device for processing water-soft cotton knitted fabrics of the present invention, including a casing 1, a dyeing chamber 2 and a heating chamber 5 are arranged in the casing 1, and the heating chamber 5 is located below the dyeing chamber 2. A battery pack 10 and a heating plate 11 are arranged in the chamber 5, the battery pack 10 is connected to the heating plate 11 by a wire, the heating plate 11 is distributed on the bottom surface of the dyeing chamber 2, and the dyestuff in the dyeing chamber 2 can be heated by the heating plate 11, Make the temperature of the dye to achieve the best dyeing effect.

[0038] The dyeing chamber 2 is provided with a first roller 3 and a second roller 4, and motors are connected to the first roller 3 and the second roller 4, and the rotation direction of the first roller 3 and the second roller 4 are opposite , the bottom of the dyeing chamber 2 is provided with a base plate 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com