Emulsifying stabilizer containing bacterial cellulose and application in coffee milk beverage thereof

An emulsification stabilizer and bacterial cellulose technology, which is applied in the field of food processing, can solve problems affecting the taste and appearance of beverages, protein precipitation and stratification, and coffee precipitation and stratification, so as to avoid precipitation and fat floating, and avoid fat The effect of floating and not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

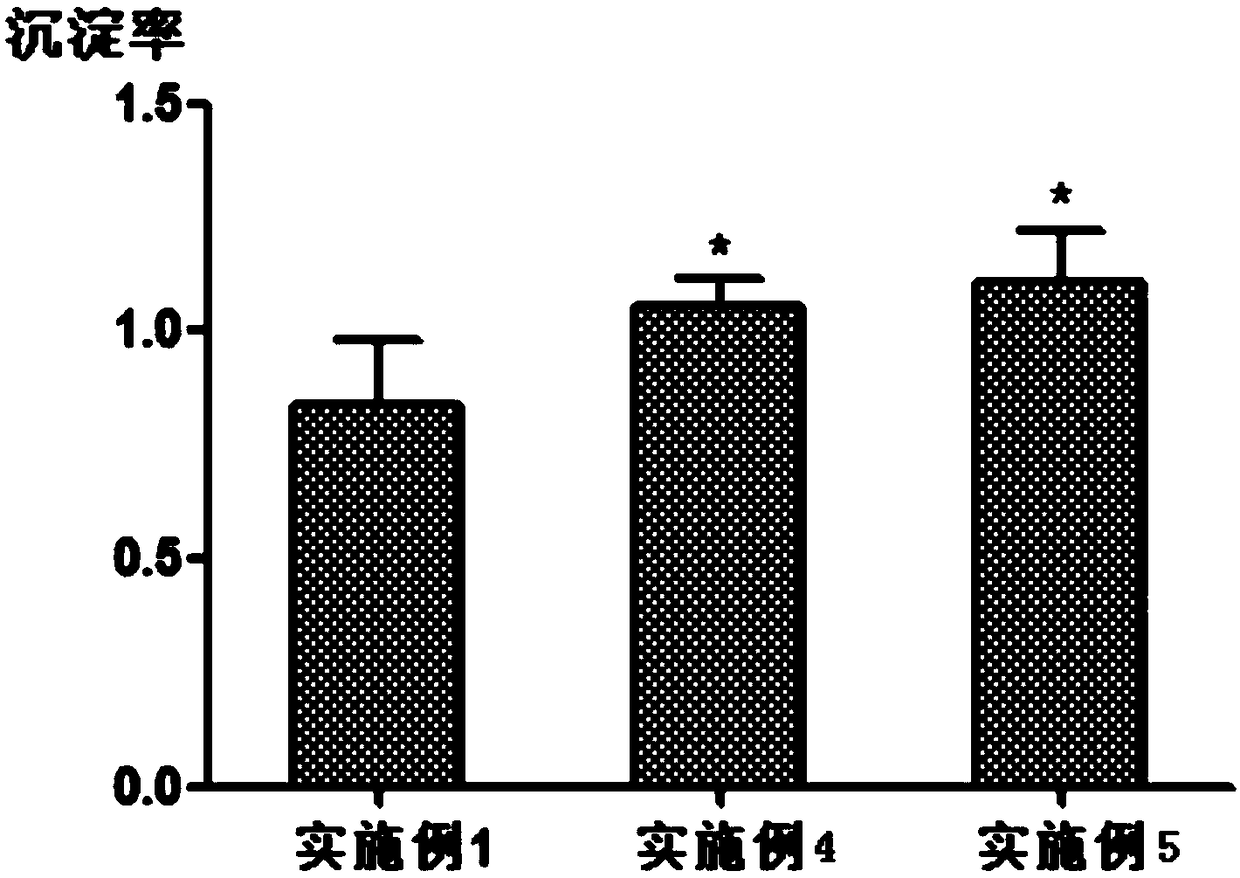

Examples

Embodiment 1

[0056] This embodiment is a preferred embodiment of the present invention.

[0057] Configure the emulsification stabilizer containing bacterial cellulose of the present invention, its components and component weight percentages are: bacterial cellulose 18%, xanthan gum 6%, sodium carboxymethyl cellulose 12%, sucrose ester 14%, monoglyceride Esters 43%, Maltodextrin 7%.

[0058] Configure the coffee milk drink containing the emulsification stabilizer of bacterial cellulose of the present invention, and its components and component weight percentages are: coffee 1.5%, baking soda 0.08%, non-dairy creamer 3%, whole milk powder 2.5%, white granulated sugar 6% %, emulsion stabilizer 0.35%, water 86.57%.

[0059] Prepare raw materials according to the above-mentioned ratio, the preparation method of coffee milk beverage of the present invention comprises the following steps:

[0060] 1. Pretreatment: Add 15 grams of coffee and 0.8 grams of baking soda into 484.2 grams of hot wate...

Embodiment 2

[0067] This embodiment is basically the same as above-mentioned embodiment 1, and its main difference is, configure the emulsion stabilizer containing bacterial cellulose of this embodiment, its component and component weight percent are: bacterial cellulose 9%, xanthan gum 3% %, sodium carboxymethylcellulose 6%, sucrose ester 7%, monoglyceride 20%, maltodextrin 42%.

[0068] Configure the coffee milk beverage containing the emulsion stabilizer of bacterial cellulose of the present invention, its components and component weight percentages are: coffee 3%, baking soda 0.16%, non-dairy creamer 5%, whole milk powder 4%, white granulated sugar 9 %, emulsion stabilizer 0.1%, water 78.74%.

[0069] Stability check:

[0070] The stability of the coffee milk beverage according to the present invention was checked one month and three months after it was made, and it was found that it could maintain good suspension stability. The solid particle components of the coffee milk beverage o...

Embodiment 3

[0072]This embodiment is basically the same as above-mentioned embodiment 1, and its main difference is, configure the emulsification stabilizer containing bacterial cellulose of this embodiment, its component and component weight percent are: bacterial cellulose 21%, xanthan gum 9 %, sodium carboxymethylcellulose 12%, sucrose ester 14%, monoglyceride 40%, maltodextrin 4%.

[0073] Configure the coffee milk beverage containing the bacterial cellulose emulsion stabilizer, its components and component weight percentages are: coffee 0.5%, baking soda 0.04%, non-dairy creamer 2%, whole milk powder 1%, white sugar 3% , Emulsion stabilizer 1%, water 92.46%.

[0074] Stability check:

[0075] The stability of Example 3 was checked one month and three months after the coffee milk drink of the present invention was made, and it was found that it could maintain good suspension stability. The solid particle components of the coffee milk beverage of the present invention can always main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com