Resistance wire liquid heater for heat management of new energy automobiles

A technology for liquid heaters and new energy vehicles, which is applied in heating/cooling equipment, vehicle parts, air handling equipment, etc. It can solve problems such as inability to guarantee high-precision flatness, small contact surface, ignition and arcing, and vehicle loss. Achieve the effect of good intelligent utilization rate and rapid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

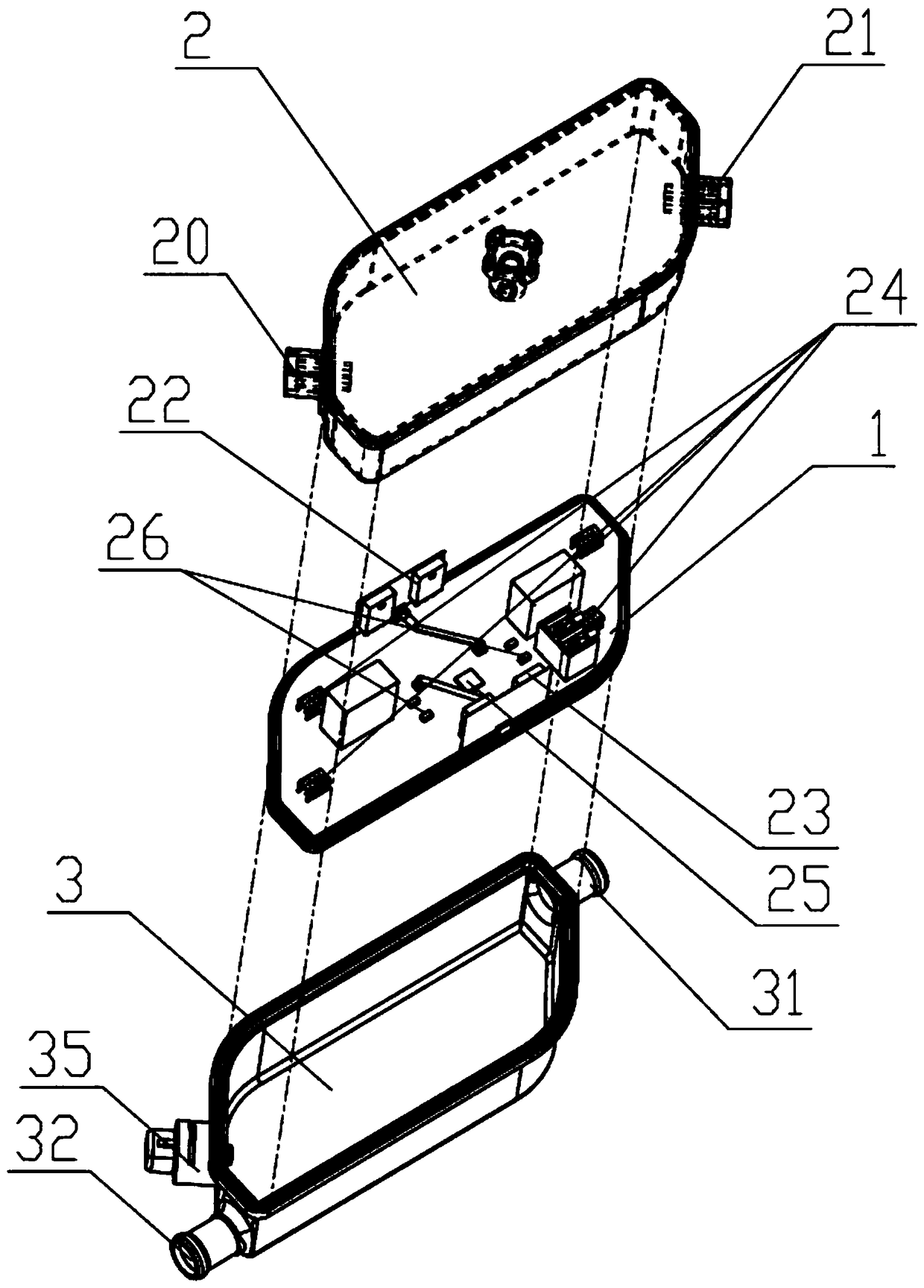

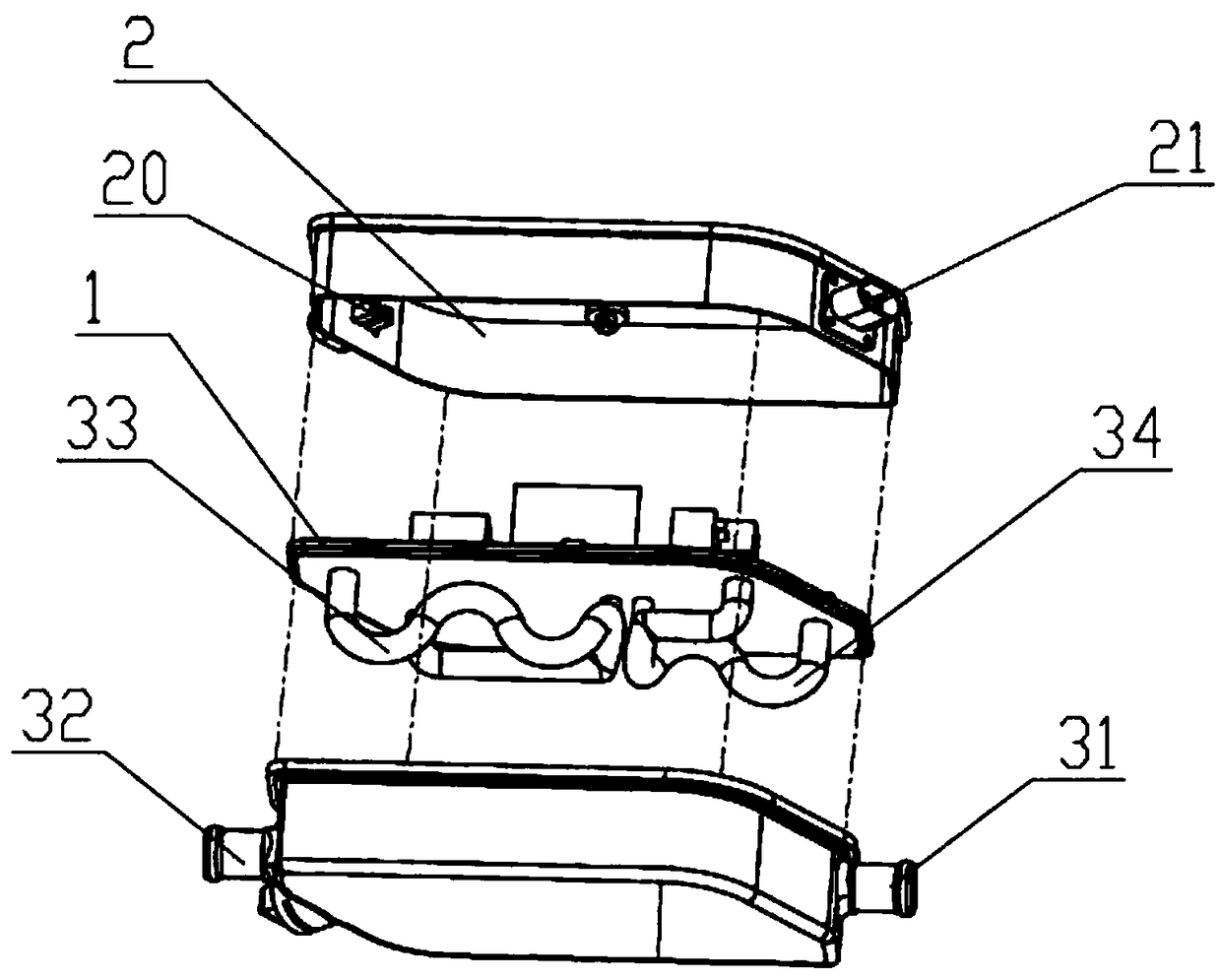

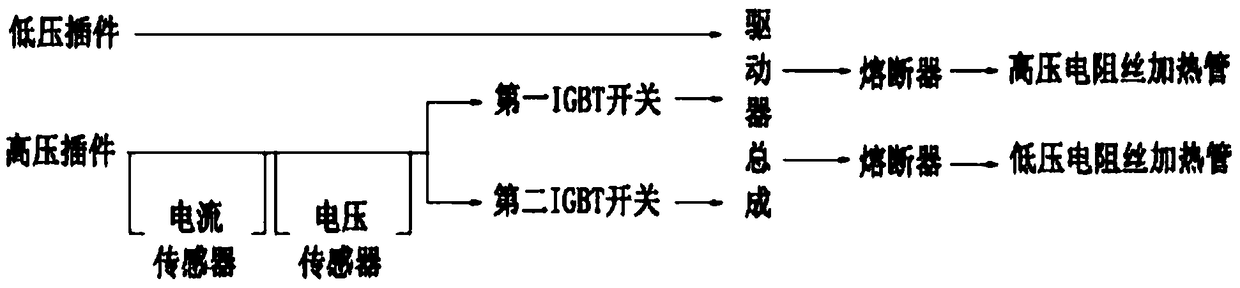

[0022] Such as Figure 1-3 as shown, figure 1 It is an explosion schematic diagram of a resistance wire liquid heater for thermal management of a new energy vehicle proposed by the present invention, figure 2 It is an explosion schematic diagram of a resistance wire liquid heater for thermal management of a new energy vehicle proposed by the present invention, image 3 It is a schematic diagram of the current flow of a resistance wire liquid heater for thermal management of a new energy vehicle proposed by the present invention.

[0023] refer to Figure 1-3, a resistance wire liquid heater for thermal management of new energy vehicles proposed by the present invention is mainly used in battery thermal management systems and air-conditioning thermal management systems, and includes a heater housing, which is provided with a separator 1 to heat The interior of the housing is separated to form a control chamber 2 and a heat exchange chamber 3; the control chamber 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com