Large-span greenhouse

A large-span, greenhouse technology, applied in the field of large-span greenhouses, can solve the problems of low land utilization, high construction cost of solar greenhouses, waste of land, etc., to facilitate mechanized operations, improve land utilization, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

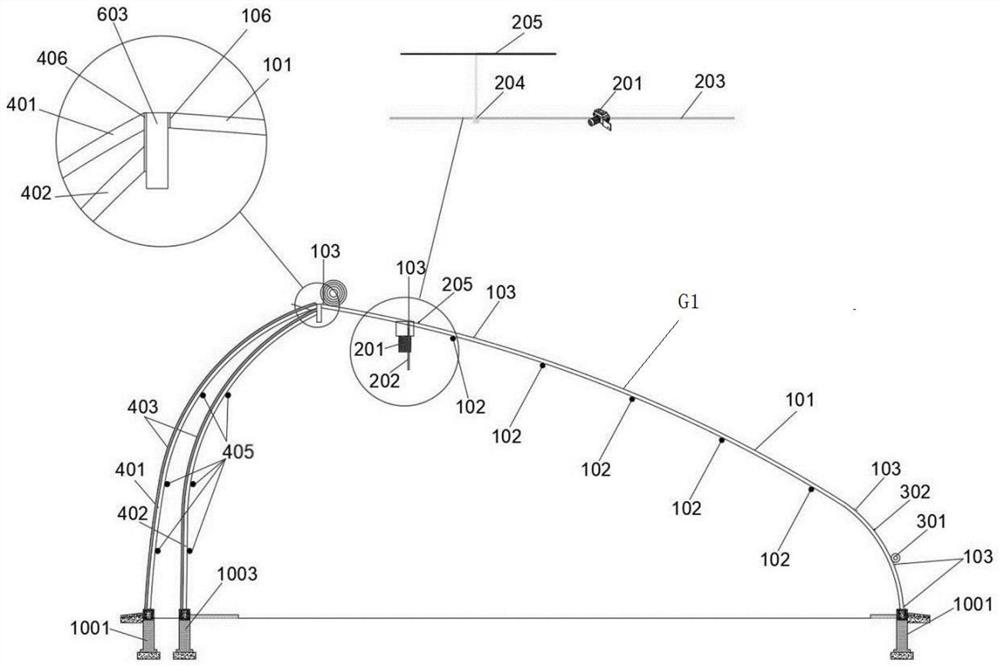

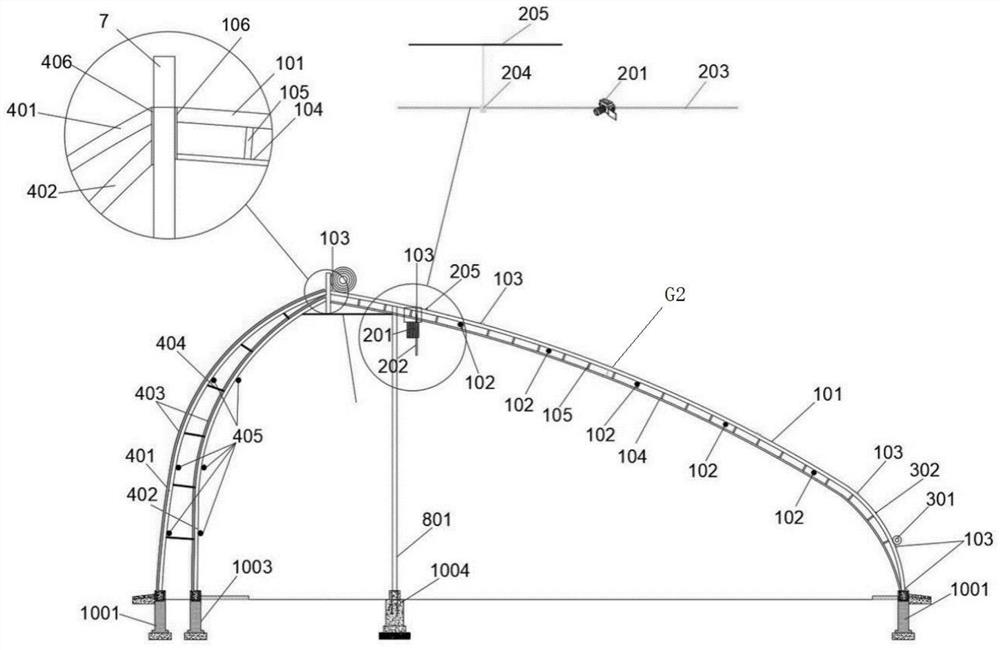

[0055] Below in conjunction with the accompanying drawings and specific embodiments, the overall scheme of the present invention is described in further detail:

[0056] Below we combine figure 1 , 2 , 3, 4, 5, the arch structure of the present invention is described in detail:

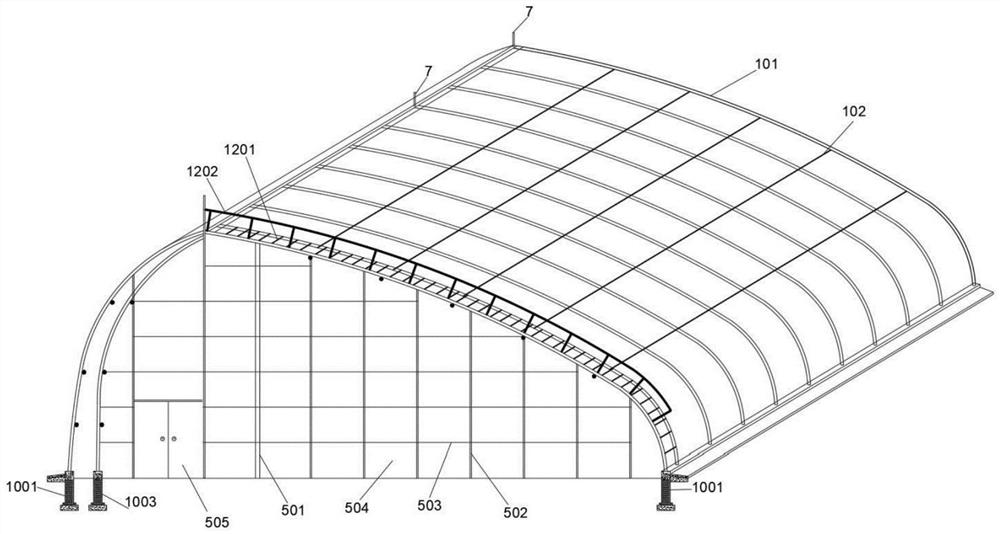

[0057] see figure 1 5, in the structure of the specific embodiment of the present invention, including the greenhouse steel arch structure, the north wall double-layer thermal insulation structure, the gable wall thermal insulation structure, the column structure, the double beam structure and the foundation and the embedded parts, the greenhouse steel arch structure and the north wall The double-layer insulation structure of the wall is connected, and the double-layer insulation structure of the gable wall is arranged on both sides of the steel arch structure of the greenhouse and the double-layer insulation structure of the north wall, among which:

[0058] The double-layer thermal insulation str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com