Preparation method of graphite oxide capable of being washed directly

A technology of water washing and graphite, which is applied in chemical instruments and methods, graphite, inorganic chemistry, etc., can solve the problems that neutral graphite oxide cannot be obtained by direct washing, it is difficult to industrial scale, and the development of graphite oxide is limited. Optimize, reduce the range of motion, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

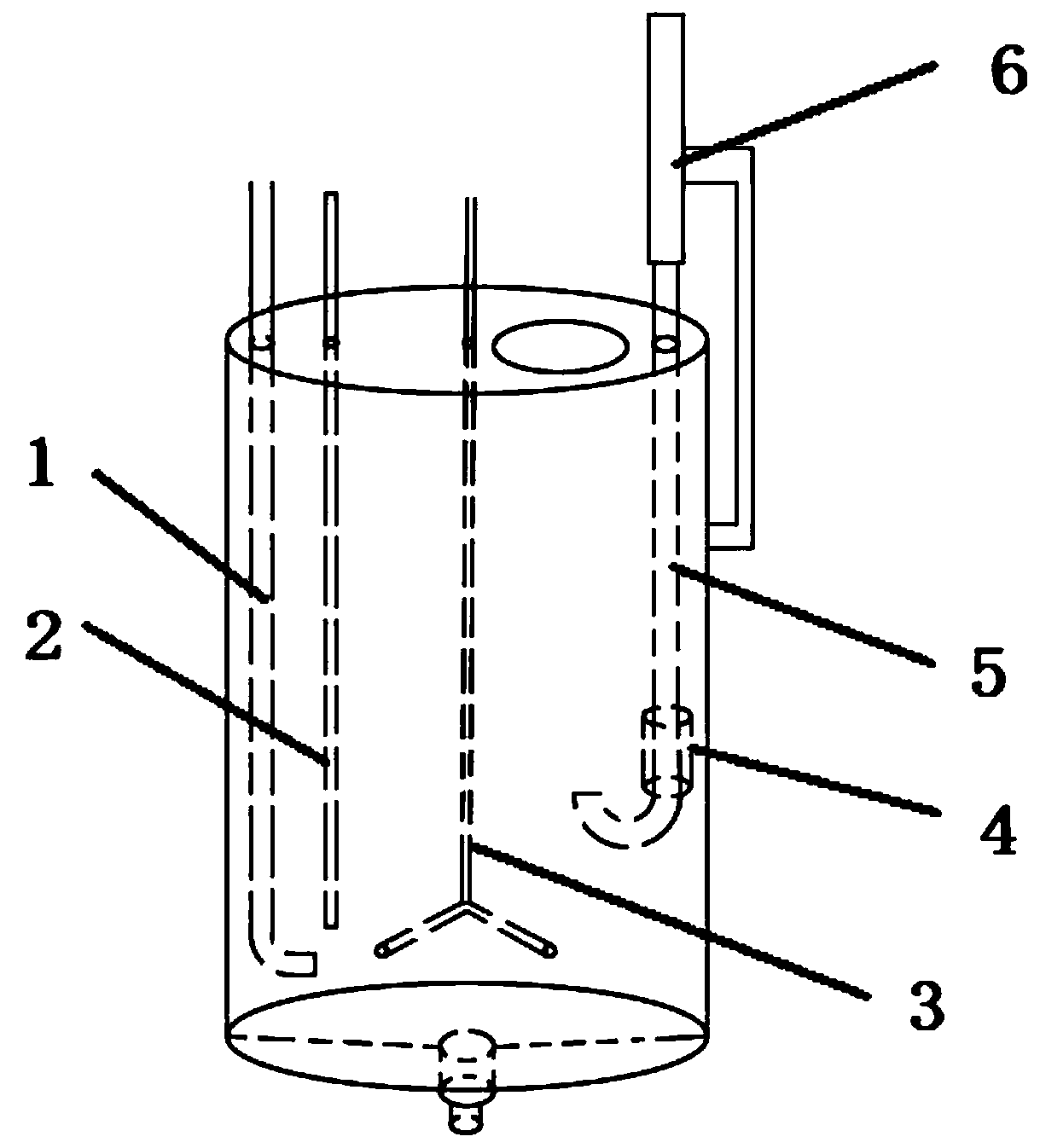

[0058] The present invention will be further described below in conjunction with the accompanying drawings.

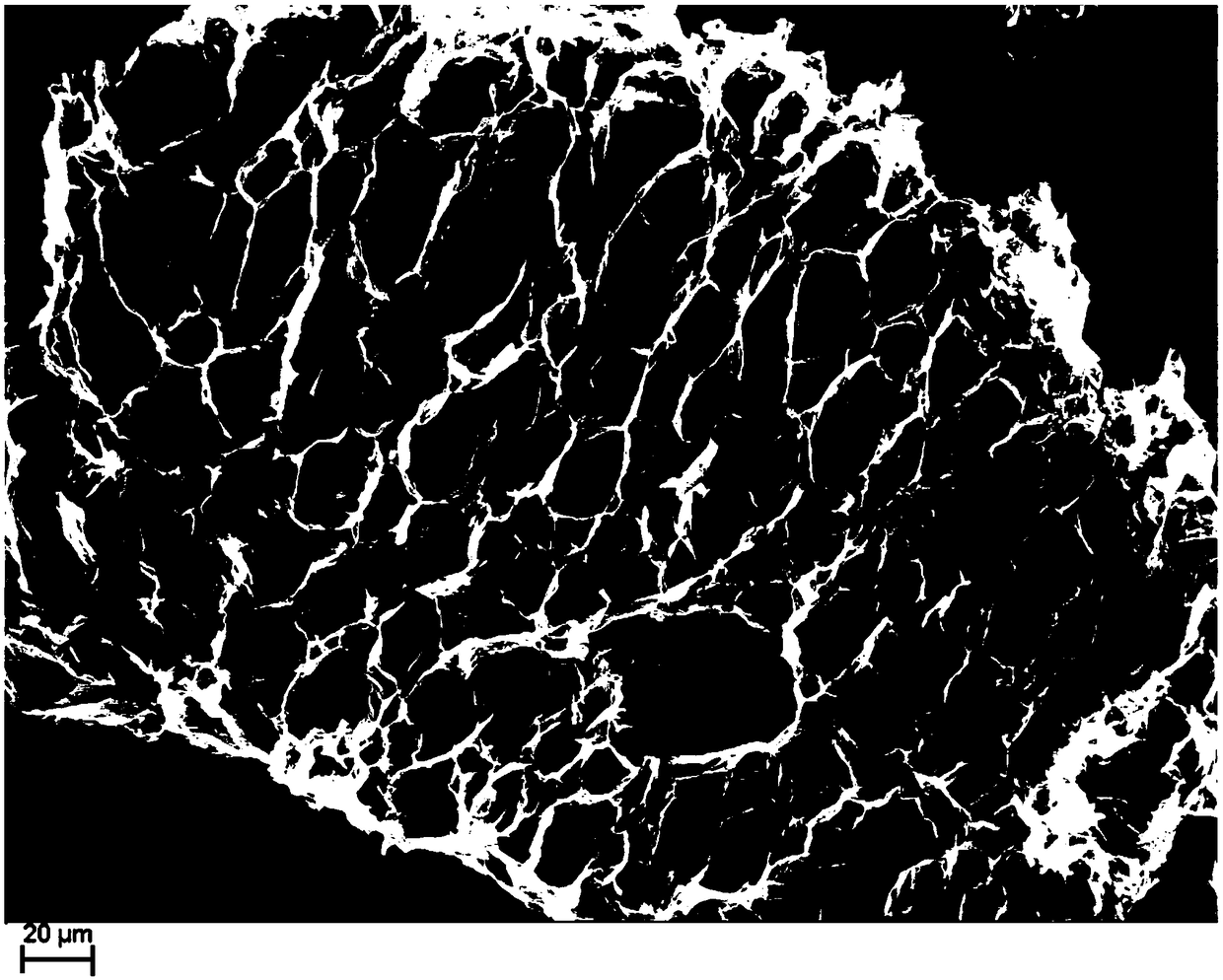

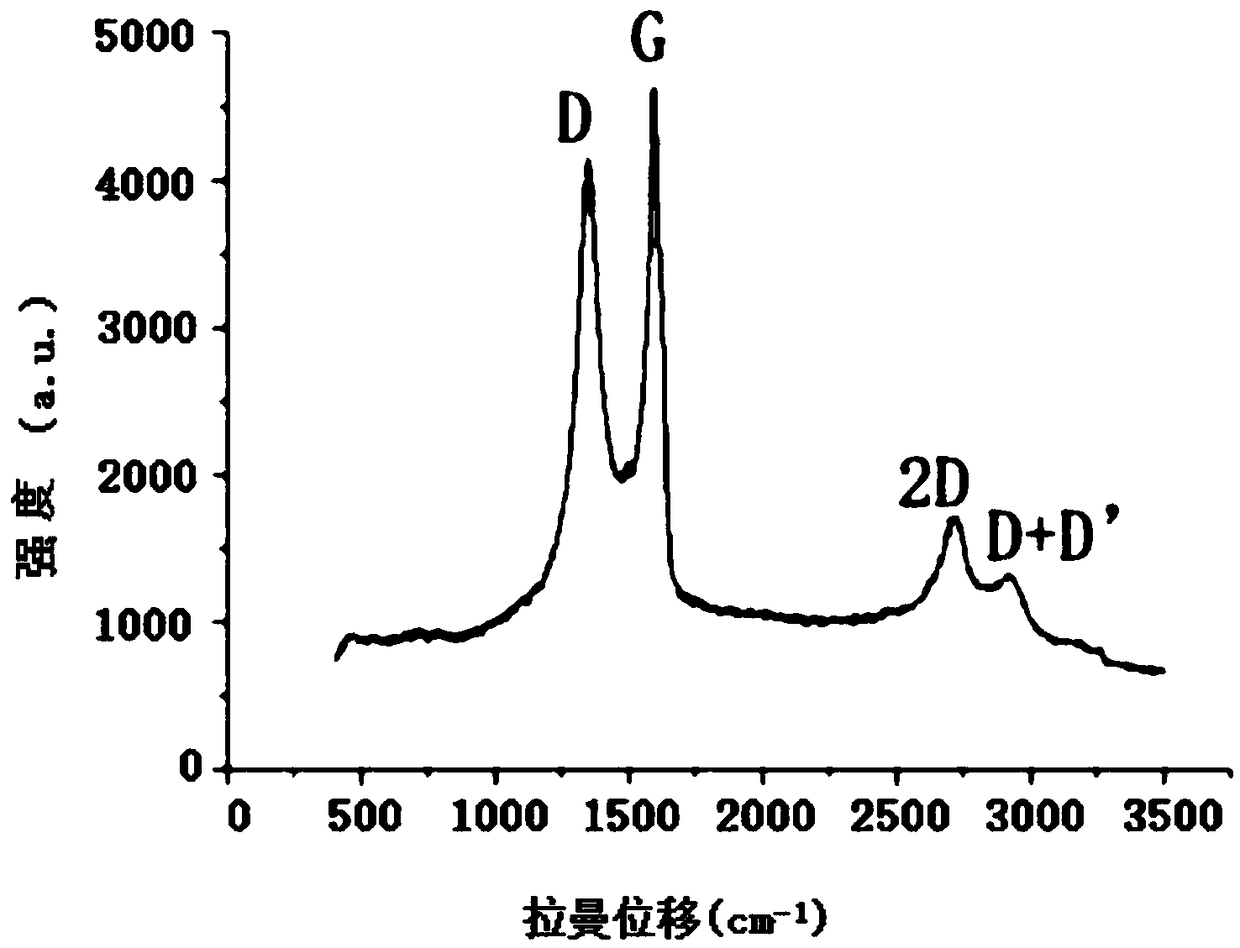

[0059] see figure 1, figure 2 , a method for preparing graphite oxide that can be directly washed with water, comprising the following steps, step 1, using flake graphite as a raw material, adding a main intercalation agent and an auxiliary intercalation agent for intercalation treatment, and intercalating at 0-45°C React for 0.1-20h to obtain graphite intercalation compound; the main intercalation agent is at least one of formic acid, acetic acid, phosphoric acid, concentrated nitric acid, and concentrated sulfuric acid; the auxiliary intercalation agent is a 30% aqueous hydrogen peroxide solution with a concentration of 90% performic acid, the concentration is at least one of 50% peracetic acid; step 2, after the graphite intercalation compound is filtered to remove excess main intercalation agent and auxiliary intercalation agent, put it into ice water, filter and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com