Concentrated treatment method for industrial production wastewater of unsymmetrical dimethylhydrazine

A treatment method and technology of unsymmetrical dimethyl hydrazine, applied in multi-stage water treatment, water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

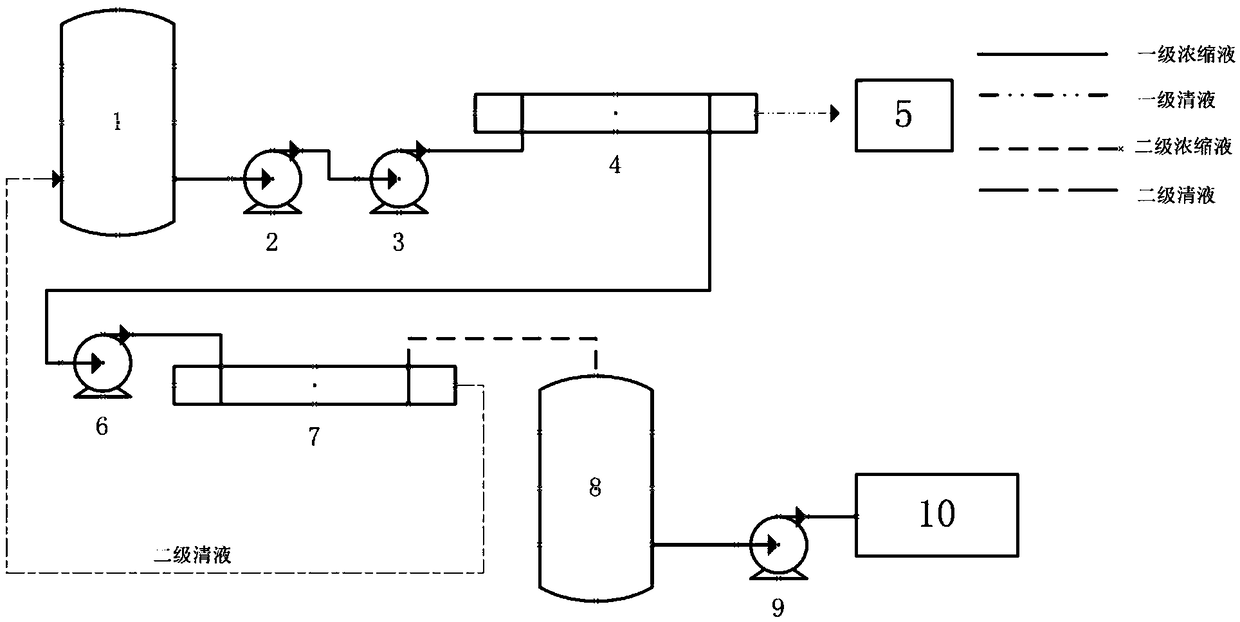

[0031] This embodiment provides a kind of concentrated treatment method of unsymmetrical dimethylhydrazine industrial production waste water, and this concentrated treatment method is the industrial production waste water of the unsymmetrical dimethylhydrazine through desalination and dealkalization treatment in buffer tank 1 (salt content is lower than 0.5%, the alkali content is less than 0.5%, and the temperature is less than 30°C) is transported to the first-stage high-pressure pump 3 by the delivery pump 2 for pressurization, and then transported to the first-stage reverse osmosis membrane system 4 for the first-stage reverse osmosis treatment after pressurization. After the primary reverse osmosis treatment, the primary clear liquid and the primary concentrated liquid are obtained, the primary clear liquid is transported to the primary clear liquid storage tank 5, and the primary concentrated liquid is transported to the secondary reverse osmosis membrane through the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com