A tft glass bod process breaking board system and method

A process and board breaking technology, applied in the field of TFT glass BOD process board breaking system, can solve the problems of product quality stability and product consistency impact, production rhythm and cost have a great impact, affecting the production efficiency of the production line, etc. Improve the mechanical repeat positioning accuracy, improve processing efficiency and yield, and facilitate equipment maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

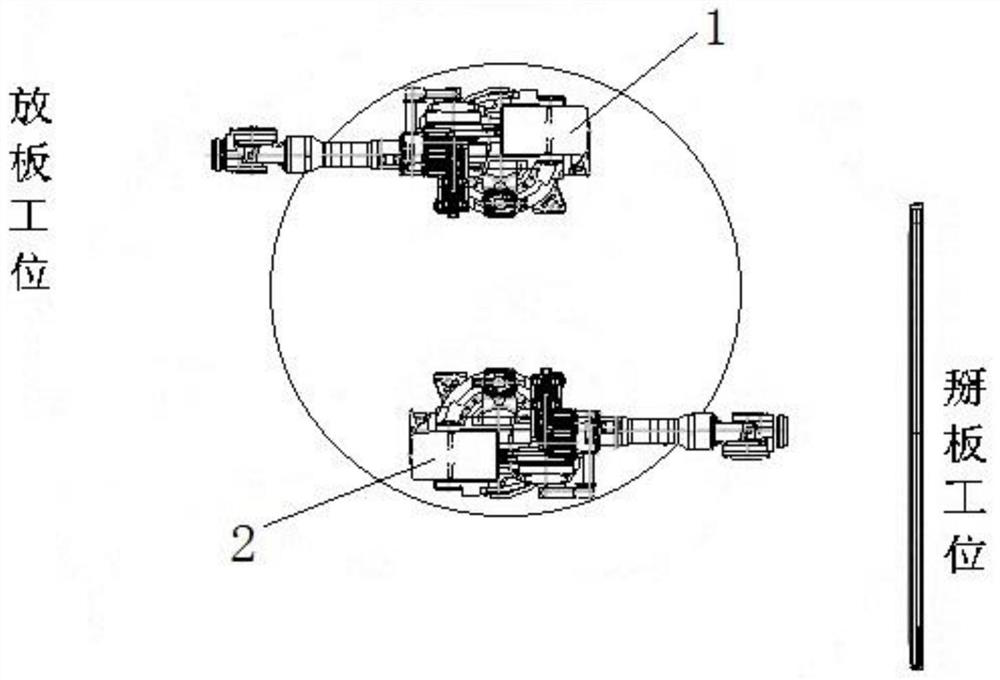

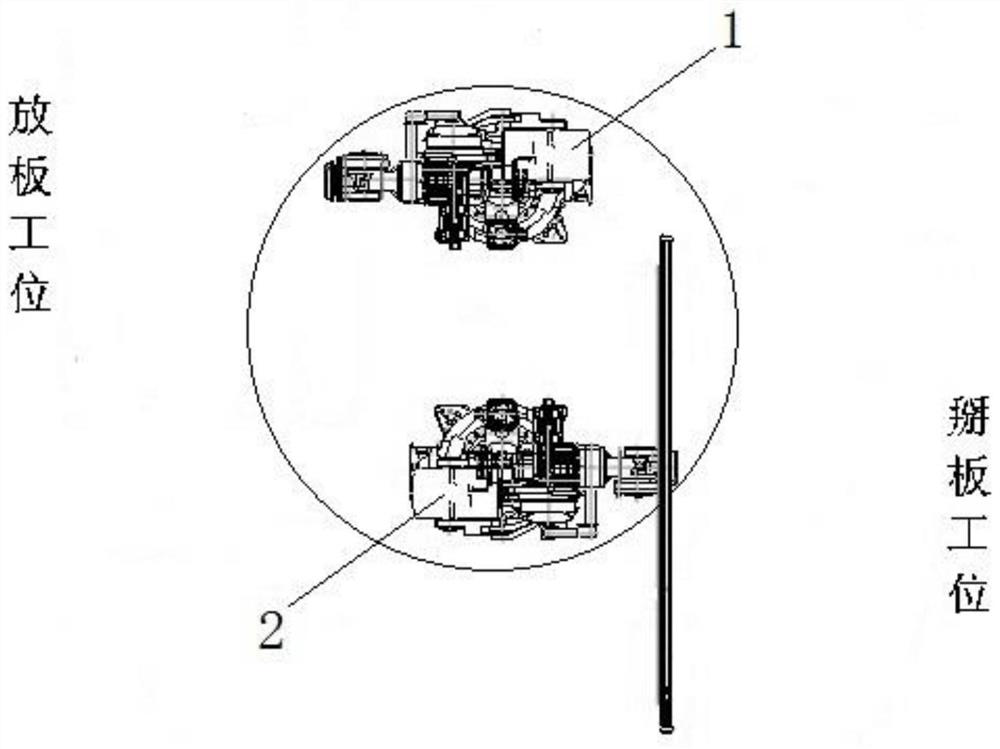

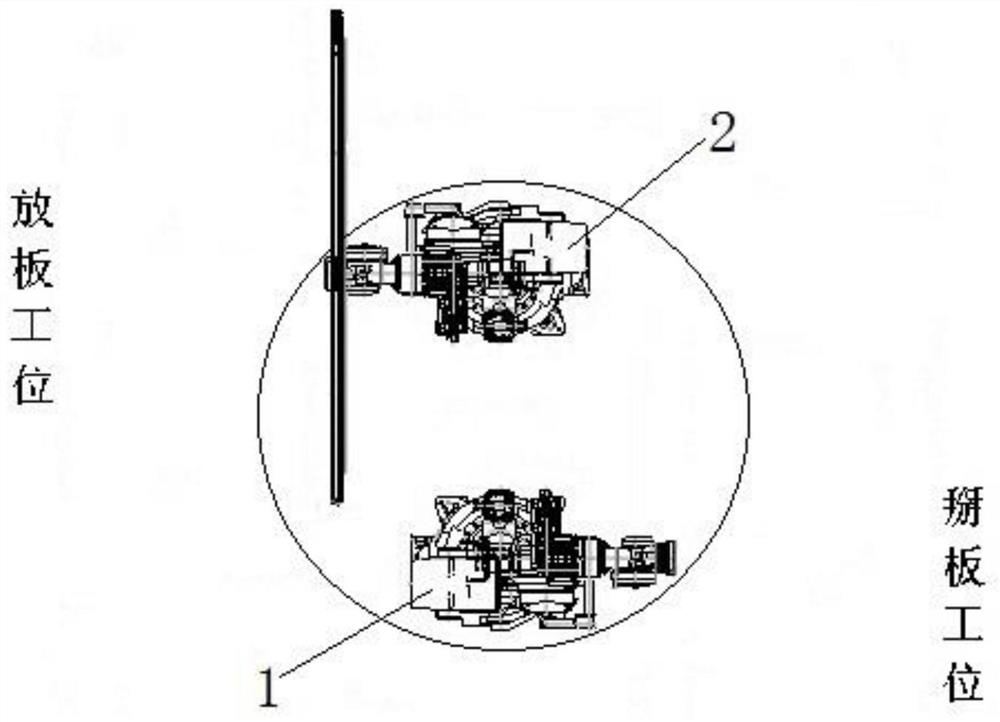

[0032] like figure 1 As shown, the first robot 1 and the second robot 2 are symmetrically arranged on the upper surface of the rotating platform, and the bases of the two robots are along the same diameter direction on the rotating platform, and the rotating platform is controlled by the external axis of the robot. When the rotating platform rotates, the two robots can rotate around the center of the rotating platform synchronously, achieving a repeatable positioning accuracy of 0.02mm.

[0033] The arms of the two robots stretch out in opposite directions, one facing the board placing station and the other facing the board breaking station. The diameter direction of the first robot 1 and the second robot 2 is perpendicular to the arms, which can compress the layout space and facilitate equipment maintenance And posture adjustment, in a limited working space, it can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com