Two-component quick-drying glue and preparation method thereof

A two-component, dry glue technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve toughness, poor high temperature and high humidity resistance, poor adhesion to plastic substrates, epoxy resin The problem of slow curing of glue, etc., to achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A two-component quick-drying adhesive, wherein the mass ratio of components A and B is 1:1;

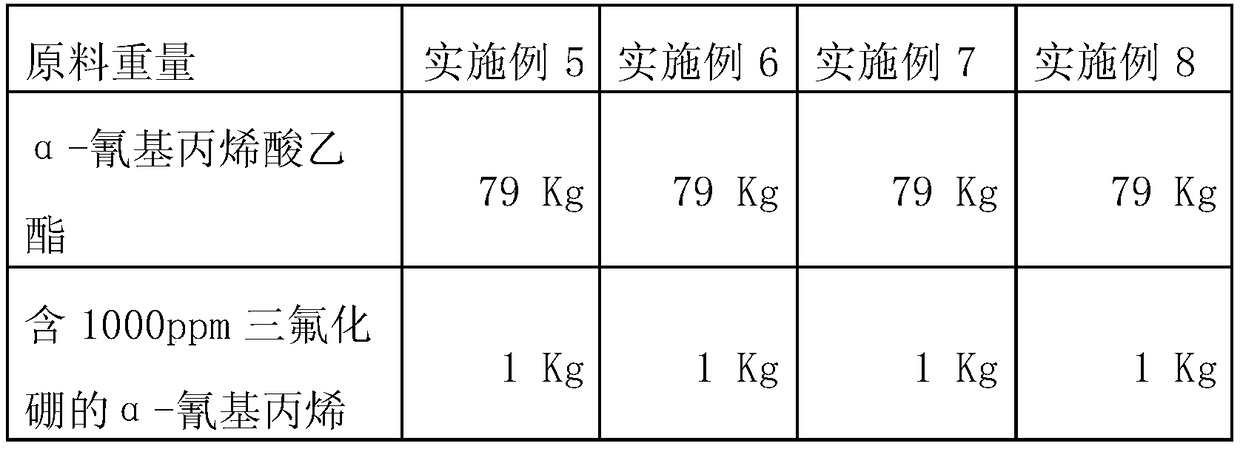

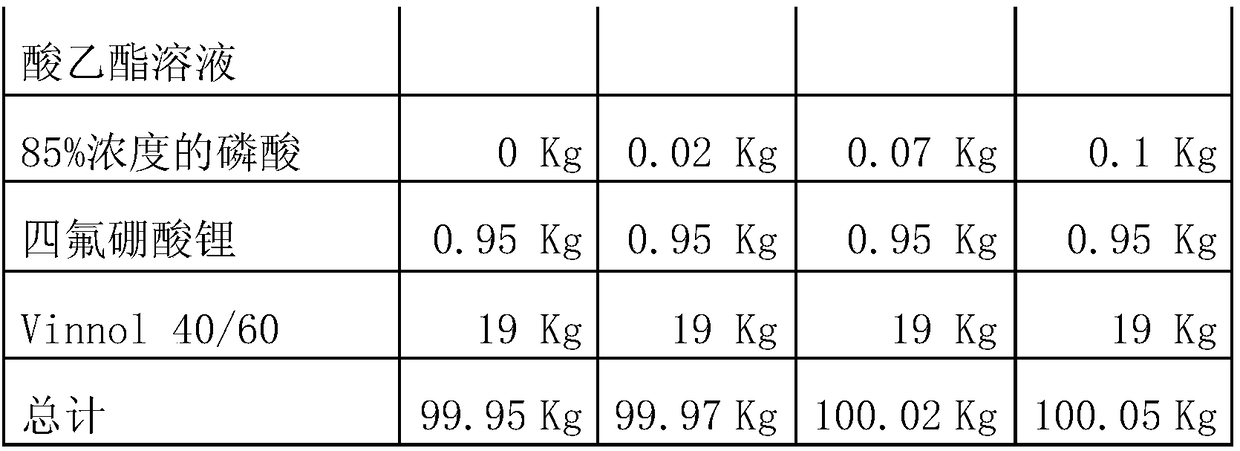

[0015] Component A: 79Kg of ethyl α-cyanoacrylate, 1Kg of ethyl α-cyanoacrylate solution containing 1000ppm boron trifluoride, 0.05Kg of 85% phosphoric acid, 0.95Kg of lithium tetrafluoroborate, VINNOL H40 from Wacker Germany / 60 vinyl resin 19Kg;

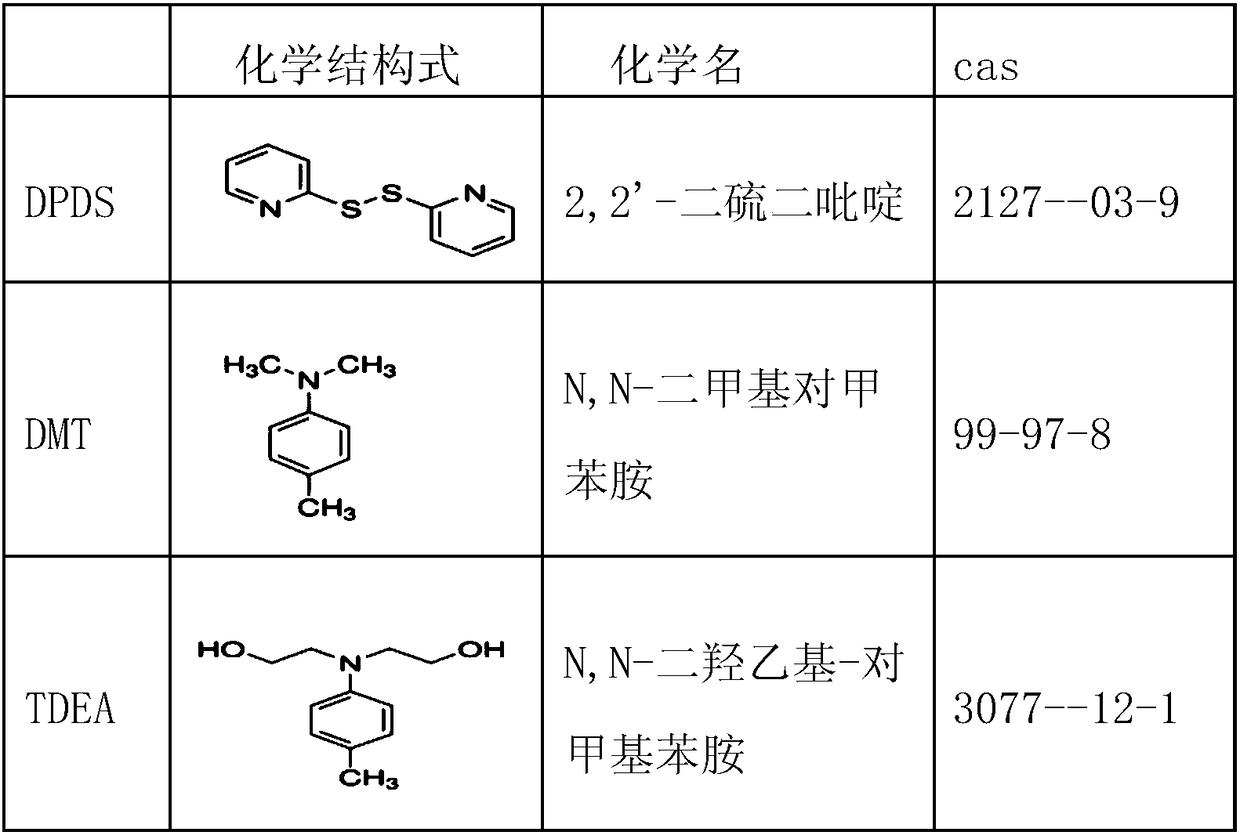

[0016] Component B: 54Kg of bis((3,4-epoxycyclohexyl)methyl) adipate (2127--03-9, Syna Epoxy28), 26Kg of epoxidized hydroxyl-terminated polybutadiene (Poly BD 600E), 0.3Kg of 2,2'-dithiodipyridine (2127--03-9, DPDS), 15.7Kg of American Chemura ABS high rubber powder Blendex 338; 4.0Kg of Cabot gas phase dioxide Silicon (CAB-O-SIL TS720).

[0017] Concrete, the preparation method of the α-cyanoacrylate ethyl ester solution containing 1000ppm boron trifluoride as stabilizer: pass boron trifluoride gas to α-cyanoacrylate ethyl ester, the liquid mass increase amount is exactly the amount of boron trifluoride The dissolved amount, unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com