Feed gas outlet ash removal device for cleaning utilization of coal

A feed and clean technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of small processing capacity and difficult industrial application, and achieve the effect of increasing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

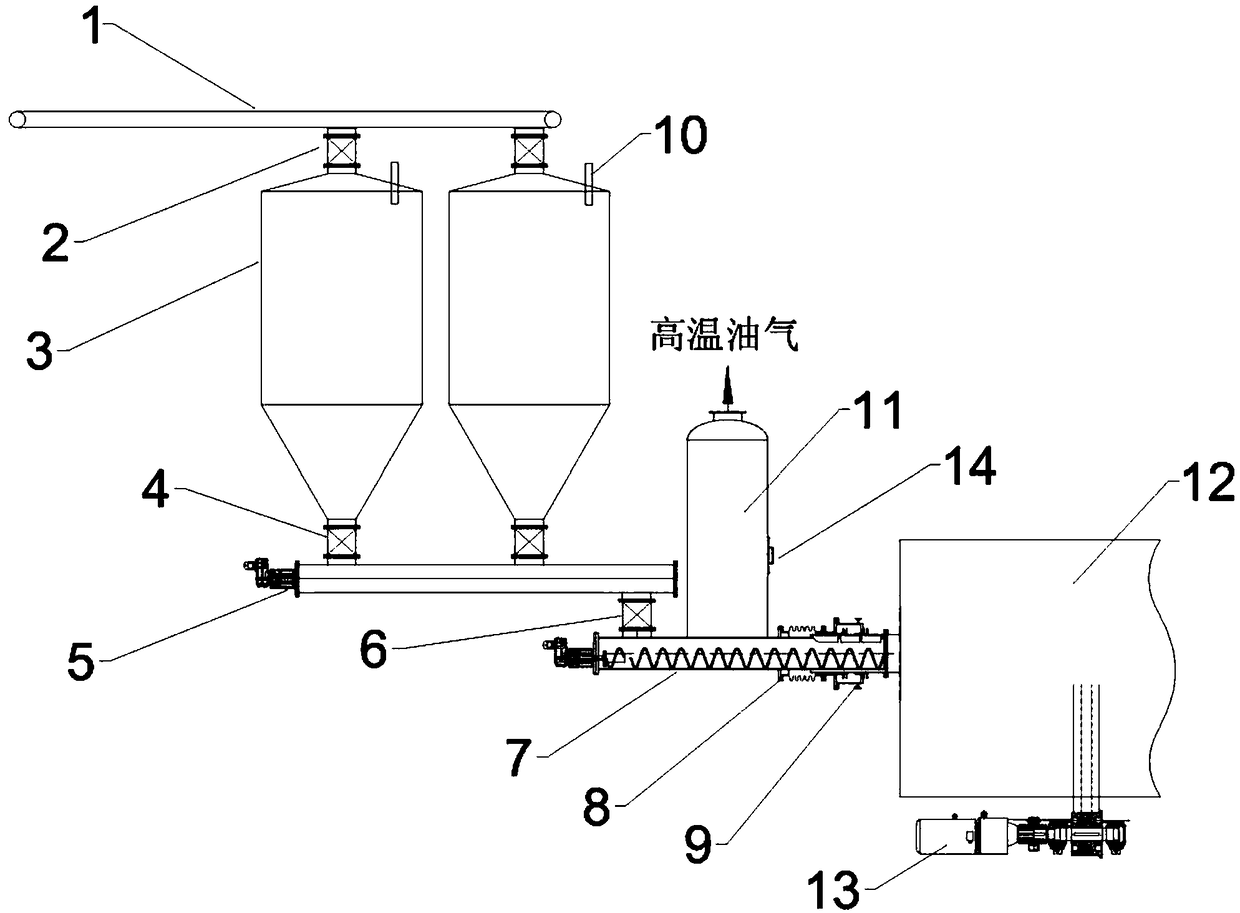

[0059] A feed-out gas ash removal device for clean utilization of coal according to the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0060] Such as figure 1 As shown, a feed and gas ash removal device for clean coal utilization includes a storage tank 3, an ash removal device 11 and a reaction kettle 12. The top of the storage tank 3 is connected to the conveying device 1 through the first valve 2; the bottom of the storage tank 3 It is connected to the screw device through the second valve 4 . The bottom end of the ash removal device 11 is connected to the feeding cylinder 7 , and the feeding cylinder 7 is connected to the screw device 5 through the third valve 6 . The reaction kettle 12 is sealed and connected with the feeding cylinder 7 through a metal compensator 8 and a dynamic and static sealing device 9 .

[0061] There are one or more storage tanks 3, which can be connected in series or in parallel. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com