Straw feed aerobic anaerobic fermentation equipment and use method thereof

A technology for anaerobic fermentation, straw feed, applied in the fields of biochemical equipment and methods, feed, bioreactor/fermenter combination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

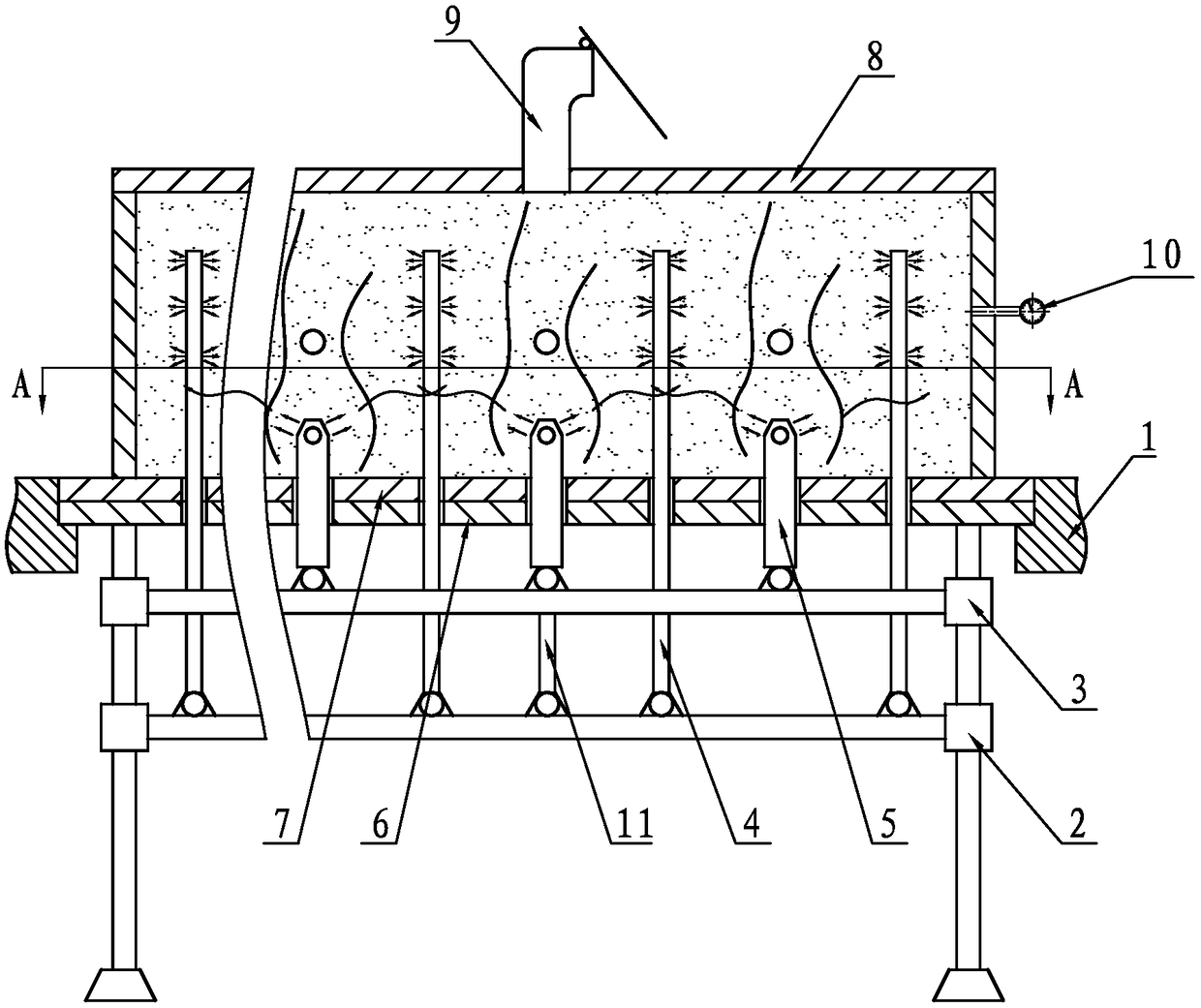

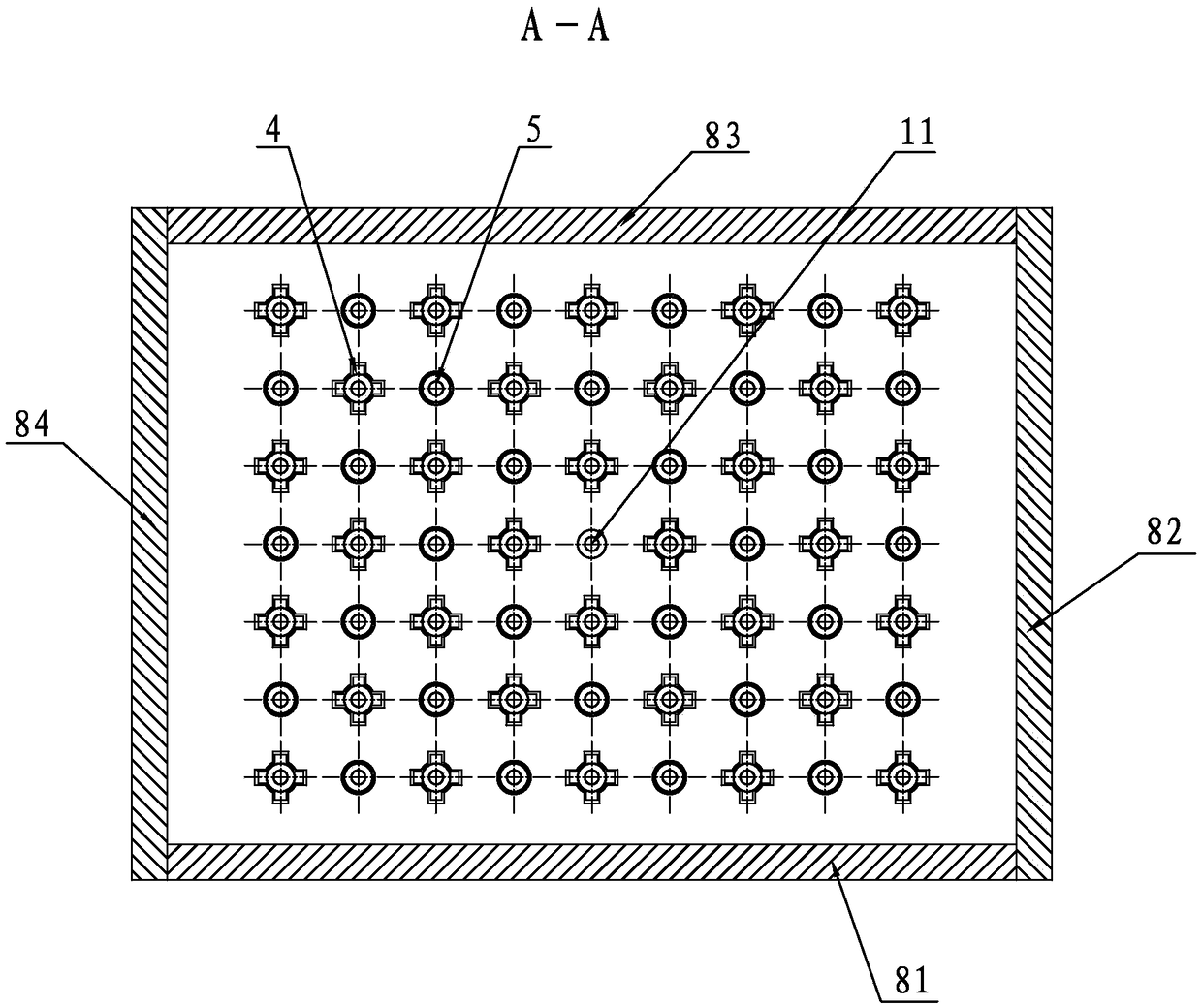

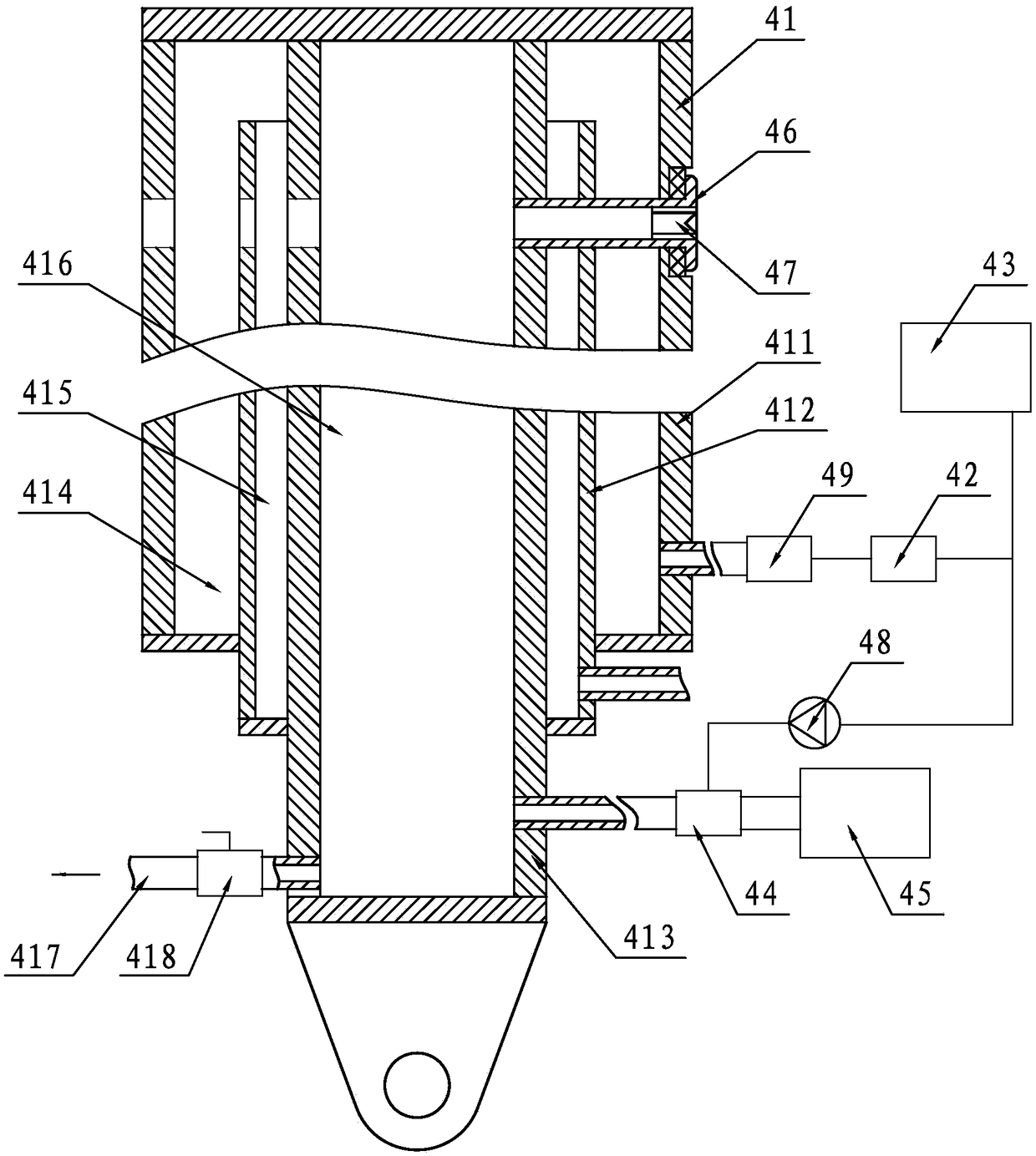

[0049] Embodiment 1: a kind of straw feed aerobic anaerobic fermentation equipment, such as Figure 1-8 As shown, it includes a support seat 1, a casing lifting mechanism 2, a spray lifting mechanism 3, a multi-functional multi-layer casing part 4, a multi-functional spray part 5, a heat insulation layer 6, a steel bottom plate 7, an insulated fermentation box 8, The pressure difference exhaust pipe 9, the side temperature measuring sensor 10 and the core temperature measuring sensor 11, the steel base plate 7 and the heat insulation layer 6 are successively arranged on the upper end of the support seat 1, and the steel base plate 7 and the heat insulation layer 6 are provided with There are guide holes to facilitate the lifting of the multi-functional multi-layer casing part 4, the multi-functional spray part 5 and the core temperature sensor 11. The casing lifting mechanism 2 and the spraying lifting mechanism 3 are arranged under the heat insulation layer 6, and the composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com