High-carbon high-chromium martensite stainless steel and preparation method thereof

A martensitic stainless steel, high carbon and high chromium technology, applied in the field of materials, can solve the problems of limited development and research, neglect, blockade, etc., and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

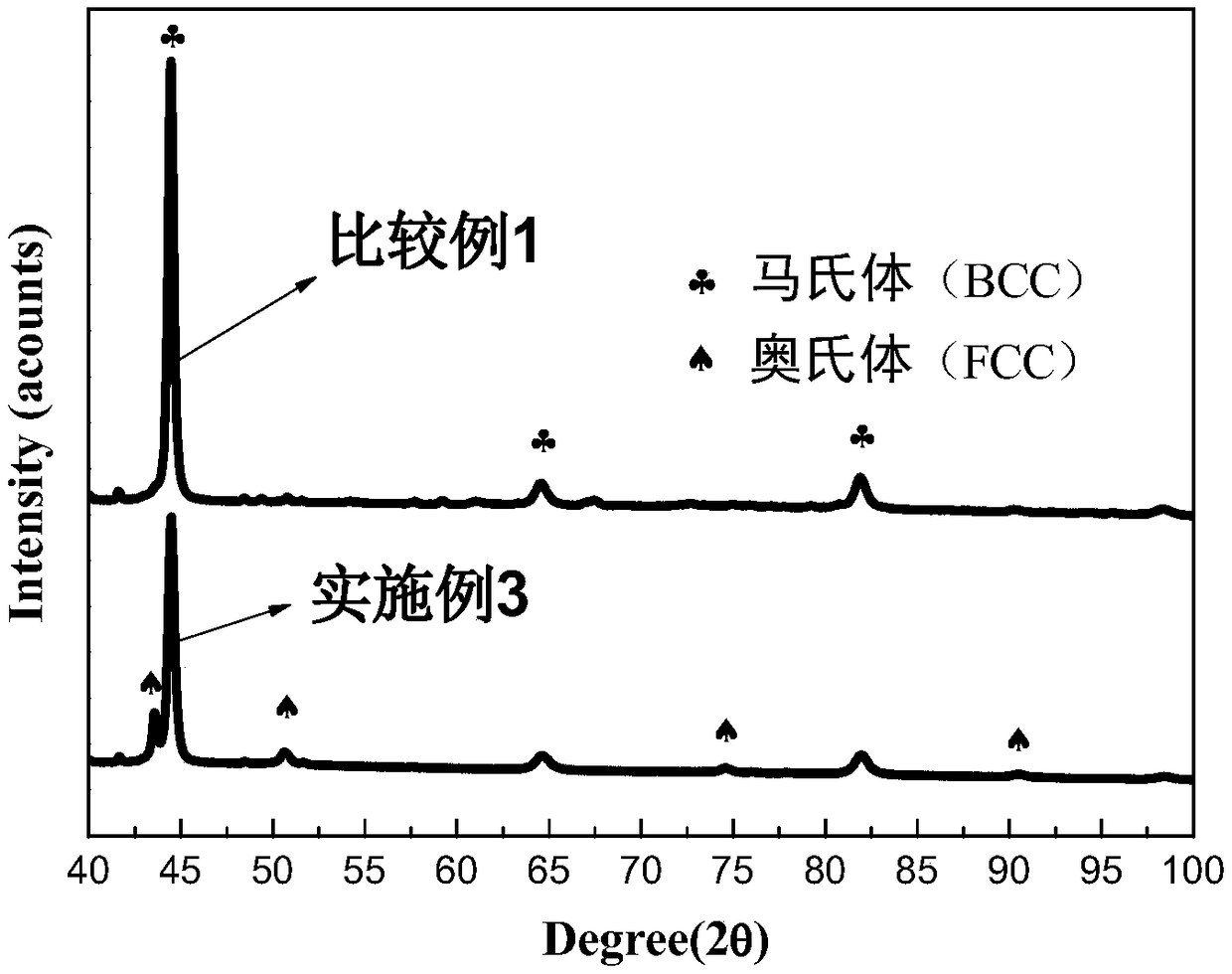

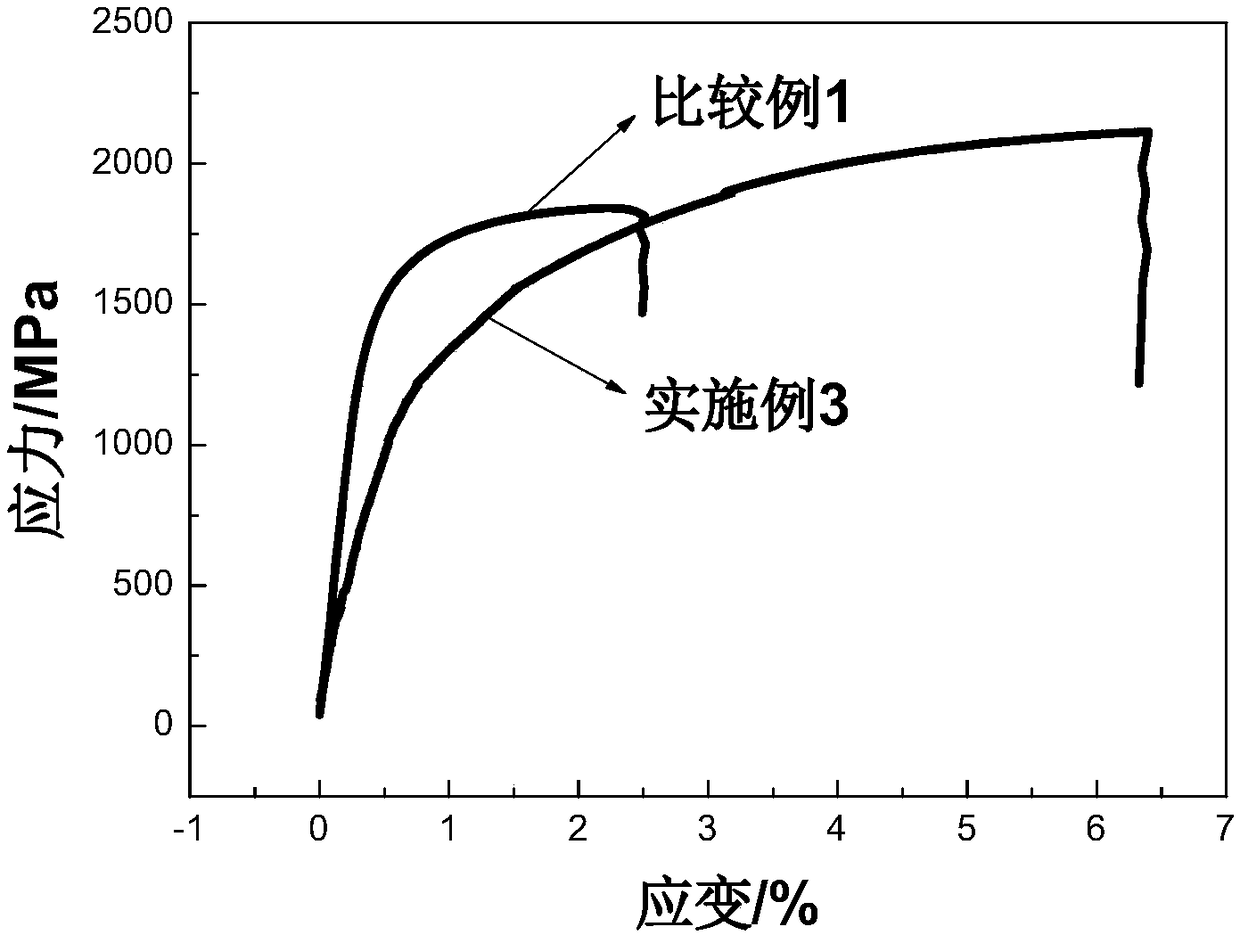

Image

Examples

preparation example Construction

[0039] The preparation process of the high-carbon high-chromium martensitic stainless steel of the present invention is: batching→smelting→casting molding→forging and thermal processing→cold processing and thermal treatment. Embodiments 1 to 5 are all prepared by the following methods, and the specific steps are as follows:

[0040] (1) mixing each chemical component according to the stated ratio, and obtaining a steel ingot through smelting and pouring;

[0041] (2) Forging the obtained steel ingot in the austenite single-phase region: the initial forging temperature is 1100°C-1200°C, the forging ratio is greater than 8, and air-cooled to room temperature after forging;

[0042] (3) Controlled rolling of the forged steel ingot: First, preliminary rolling in the recrystallization zone: the rolling temperature is 1050 ° C ~ 1200 ° C, the reduction of each rolling pass is controlled at 20 ~ 25%, and the total reduction is controlled 80-90%, air-cooled to room temperature after h...

Embodiment 1

[0046] In this embodiment, the chemical composition of high carbon and high chromium martensitic stainless steel is: C: 0.41wt.%, Cr: 14.17wt.%, Mo: 0.56wt.%, V: 0.14wt.%, Mn: 0.49wt .%, Si: 0.35wt.%, Ni: 0.17wt.%, O: 20ppm, N: 250ppm, S: 45ppm, P: 280ppm, and the balance is iron.

Embodiment 2

[0048] In this embodiment, the chemical composition of high carbon and high chromium martensitic stainless steel is: C: 0.44wt.%, Cr: 14.8wt.%, Mo: 0.53wt.%, V: 0.13wt.%, Mn: 0.49wt .%, Si: 0.60wt.%, Ni: 0.16wt.%, O: 23ppm, N: 420ppm, S: 30ppm, P: 238ppm, and the balance is iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com