Special processing equipment for milling instead of turning

A technology of processing equipment and milling head, which is applied in the field of special processing equipment for milling instead of turning, can solve the problems of time-consuming and laborious clamping and alignment process, the size of the processing surface in the processing range and the stroke limit of vertical lathes, etc., so as to improve the processing efficiency and The effects of machining accuracy, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

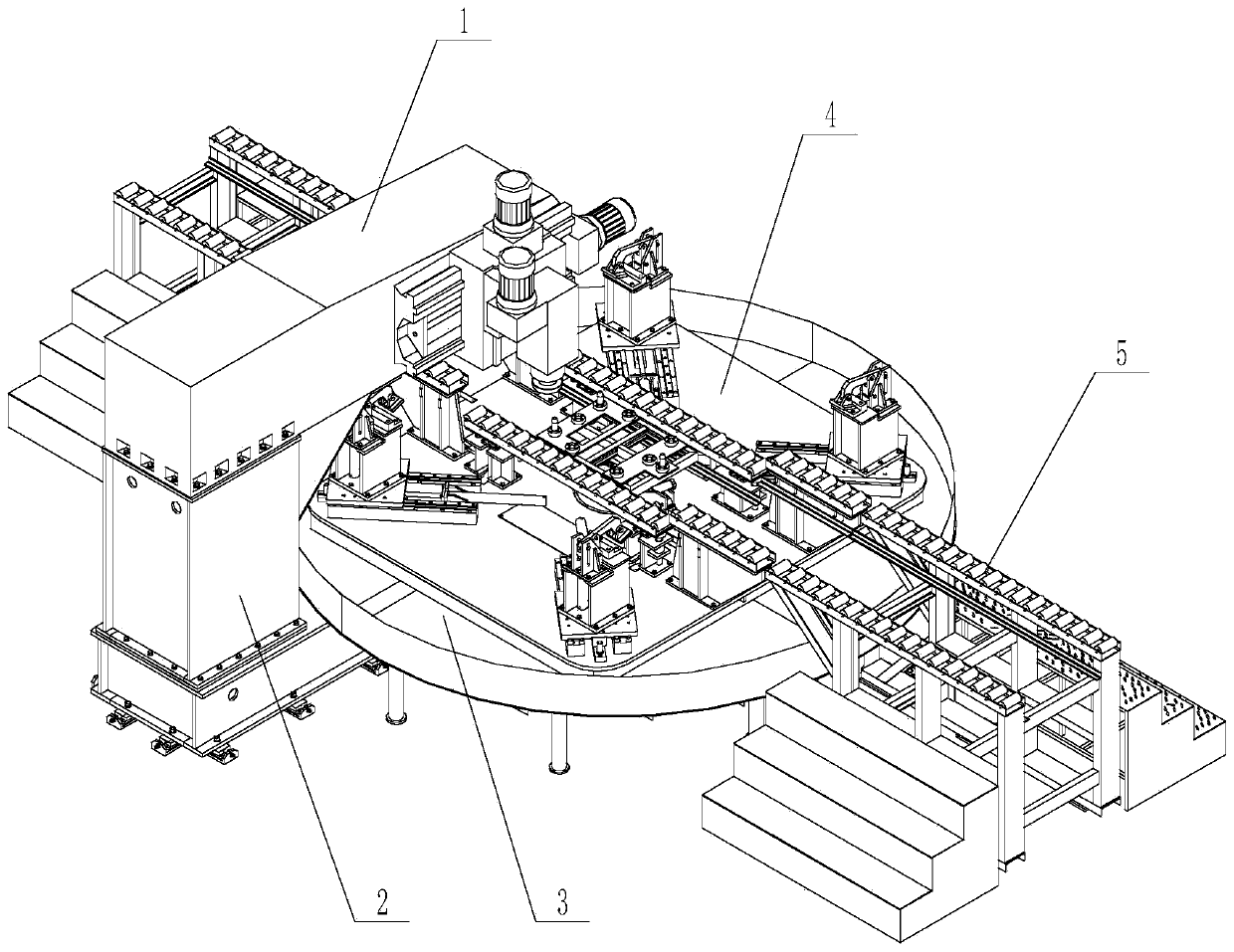

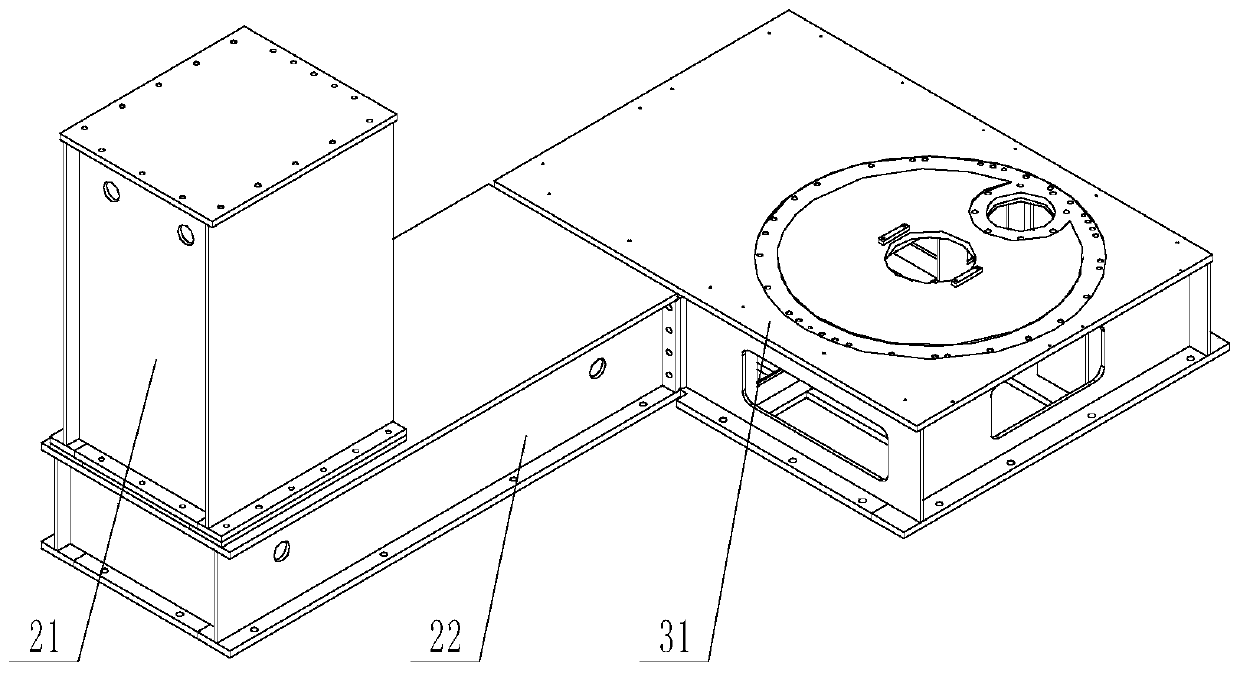

[0031] Such as figure 1 As shown, the special processing equipment for milling instead of turning includes a support component 2, a power component assembly 1, a slewing mechanism 3, a hydraulic system 4, and a positioning travel device 5. The power component assembly 1 is arranged above the support component 2, and the power component assembly A milling head 16 that can move up, down, left, and right is provided on the Cheng 1, and a rotary mechanism 3 that cooperates with the power component assembly 1 is provided on one side of the supporting part 2. The rotary mechanism 3 is provided with a hydraulic system 4, and the hydraulic system 4 is connected with the positioning travel device 5 fit.

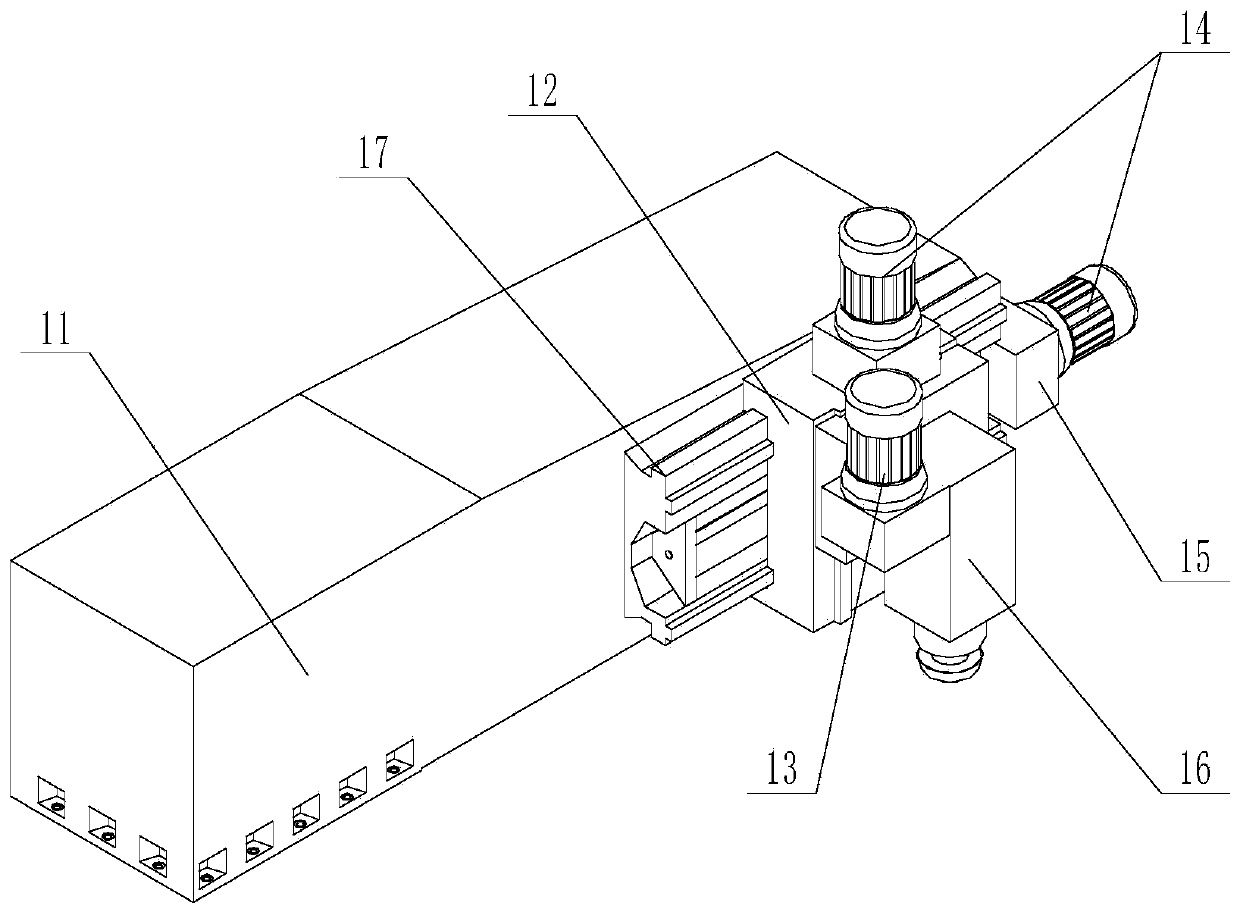

[0032] Such as figure 2 As shown, the power component assembly 1 includes an integral cast beam 11, the beam 11 is provided with a fixedly connected double rail 17, the double r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com