Single-engine three-propeller type air-electric hybrid ship power system

A power system and paddle-type technology, applied in the field of power system, can solve the problems of battery capacity limitation of battery life, unable to achieve high-performance acceleration and self-control, etc., to increase power coverage, improve acceleration and deceleration performance and reverse the boat. performance, improved shock and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

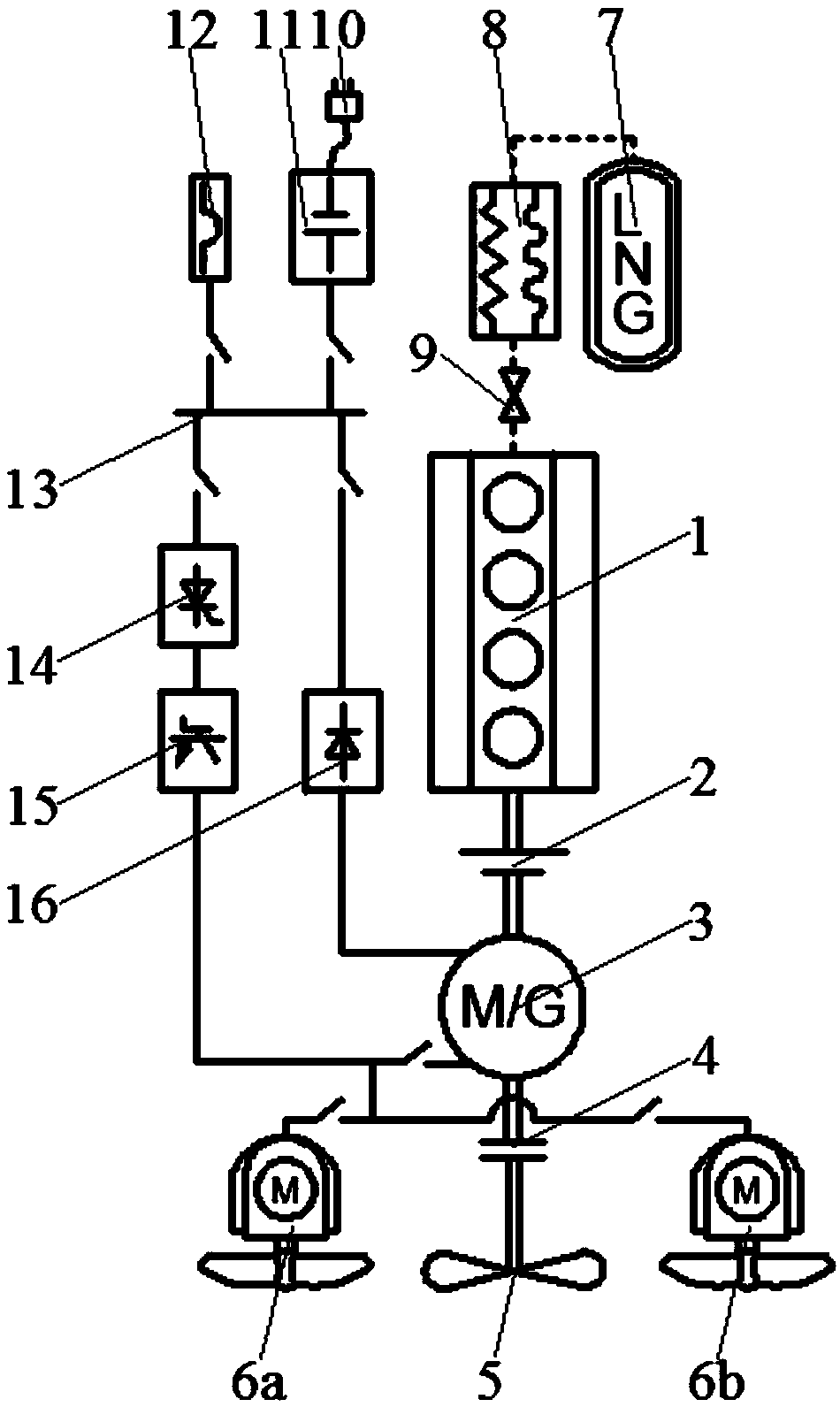

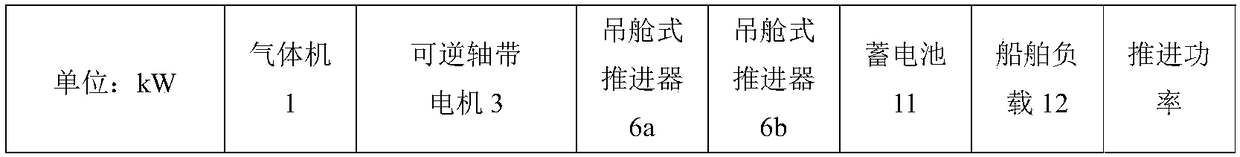

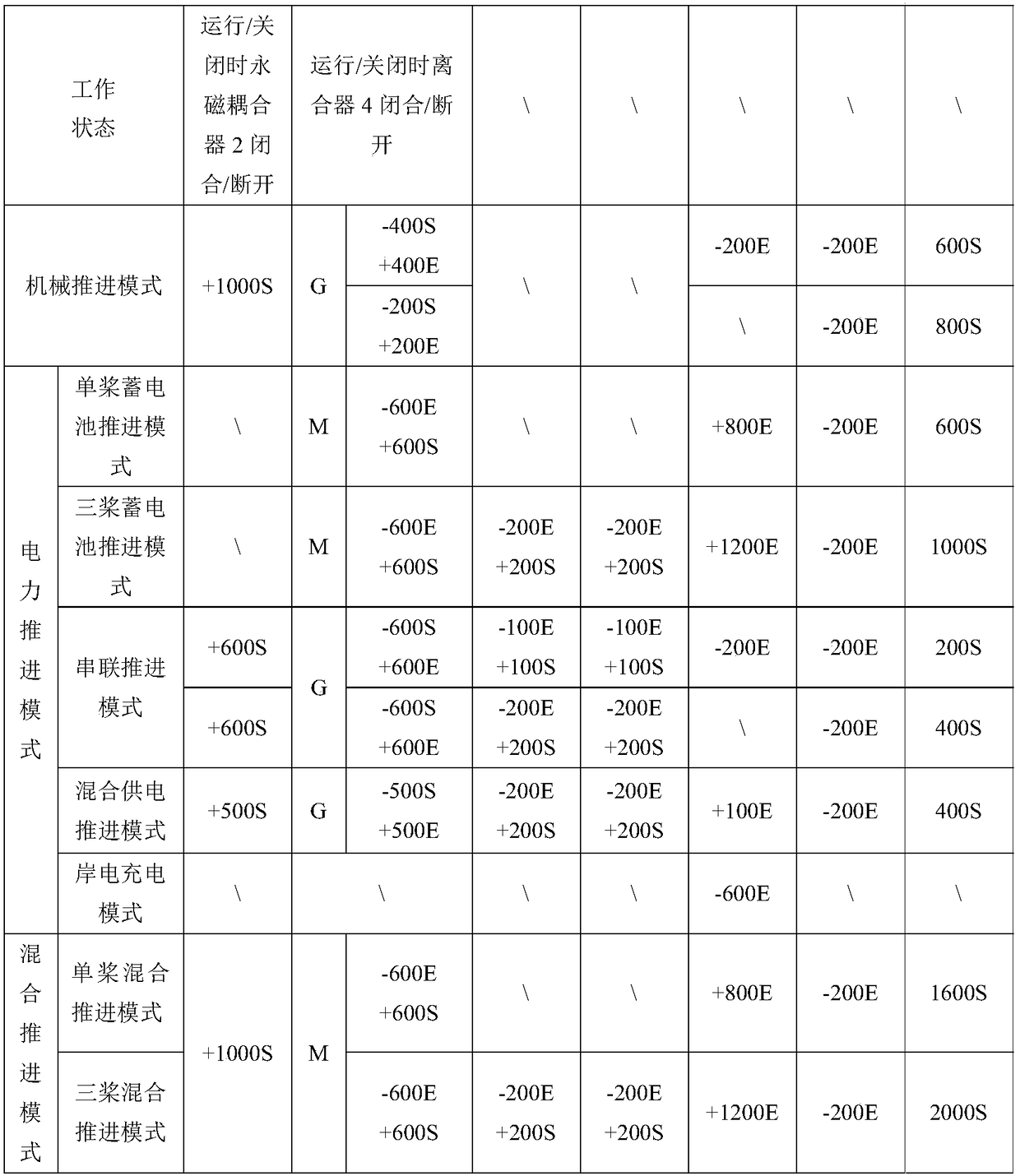

[0034] combine figure 1 , a single-machine three-blade gas-electric hybrid ship power system of the present invention includes a gas machine 1, a permanent magnetic coupler 2, a reversible shaft motor 3, a clutch 4, a propeller 5, pod propellers 6a and 6b, and liquefied natural gas Tank 7 , gas supply device 8 , gas valve 9 , charging plug 10 , storage battery 11 , ship load 12 , switchboard 13 , inverter 14 , frequency converter 15 , and rectifier 16 . The connection relationship is as follows: the output end of the gas machine 1 is connected to the input end of the reversible shaft motor 3 through the permanent magnetic coupler 2, the output end of the reversible shaft motor 3 is connected to the propeller 5 through the clutch 4, and the liquefied natural gas tank 7 is connected to the gas The supply device 8 is gas-connected, and the natural gas is delivered t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com