A kind of purification method of myrcene

A purification method and myrcene technology, applied in the field of chemical separation, can solve the problems of difficult purification and low product purity, and achieve the effects of high purity, high yield and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

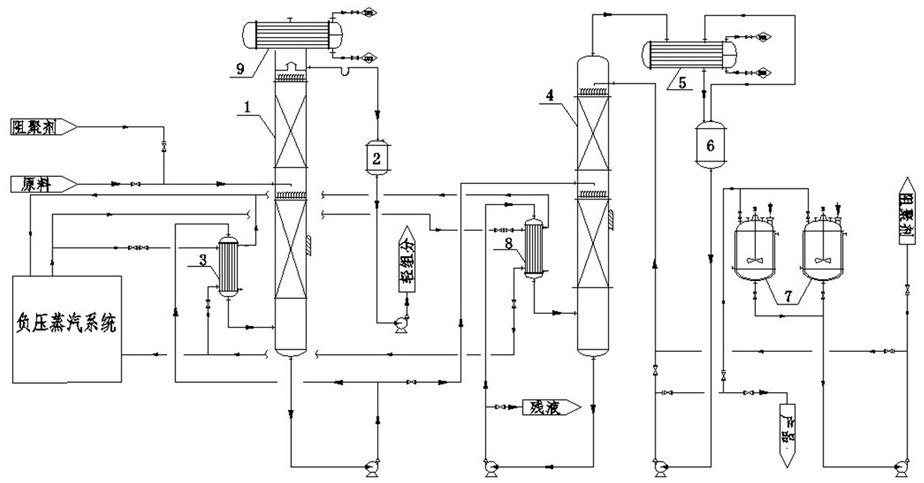

Image

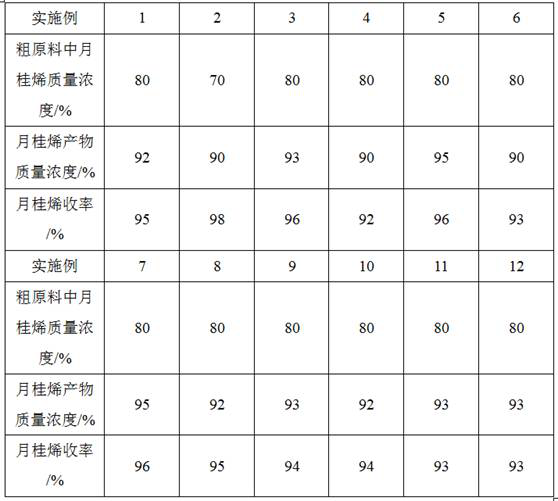

Examples

no. 1 Embodiment

[0025] A method for purifying myrcene, comprising the steps of:

[0026] The raw material to be purified comes from the raw material tank area. After the flow rate is corrected, it is continuously passed into the first rectification tower, and a polymerization inhibitor is added to the tower at the same time; the main task of the first rectification tower is to remove light components at the top of the tower. Then the materials in the tower bottom are obtained in the bottom of the tower, and the materials in the top bottom are transported by pumps in the bottom of the tower, part of them are sent to the heater for circulation heating, and part (the first mixture) enters the second rectification tower. The raw materials are fed from the middle of the tower section, and the falling film reboiler is used in the tower kettle to heat the materials. The top of the tower adopts the internal reflux method, and after being condensed by 7°C chilled water, part of the light components ar...

no. 2 Embodiment

[0031] The difference between this example and the first example is that the mass fraction of myrcene in the raw material to be purified is 70%.

no. 3 Embodiment

[0033] The difference between this embodiment and the first embodiment is that the reboilers used in the bottoms of the first rectification tower and the second rectification tower are wiped film reboilers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com