Method for preparing 5-ethoxymethylfurfural by glucose

A technology of ethoxymethylfurfural and glucose, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve difficult problems and achieve less waste acid and less environmental pollution , the effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

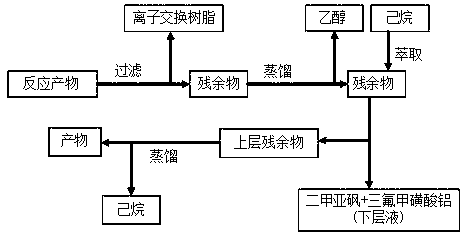

Image

Examples

Embodiment 1

[0016] Embodiment 1: the method utilizing glucose to prepare 5-ethoxymethylfurfural specifically comprises the following steps:

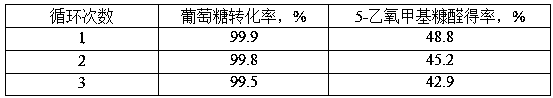

[0017] With glucose as the substrate, aluminum trifluoromethanesulfonate and ion exchange resin Amberlyst 15 as the co-catalyst, add to a stainless steel autoclave equipped with 5mL of absolute ethanol and 5mL of dimethyl sulfoxide, at an oil bath temperature of 150°C React by magnetic stirring at a speed of 800r / min for 8.2h. After the reaction is completed, immediately immerse the reactor in cold water to cool down. After the temperature of the reactor drops to normal temperature, filter the reaction mixture and collect the filtrate. High-performance liquid chromatography (HPLC) Analysis and calculation to obtain the yield of target product 5-ethoxymethylfurfural is 48.8%, wherein the addition of glucose is 0.2mol / L, the consumption of aluminum trifluoromethanesulfonate is 0.052mol / L, and the consumption of ion exchange resin Amberlyst 15 is 5.56g...

Embodiment 2

[0022] Embodiment 2: the method utilizing glucose to prepare 5-ethoxymethylfurfural specifically comprises the following steps:

[0023] With glucose as the substrate, aluminum trifluoromethanesulfonate and ion exchange resin Amberlyst 15 as the co-catalyst, put into a stainless steel autoclave with 7mL of absolute ethanol and 3mL of dimethyl sulfoxide, under the oil bath temperature of 160°C React by magnetic stirring at a speed of 700r / min for 5h. After the reaction is completed, immediately immerse the reactor in cold water to cool down. After the temperature of the reactor drops to normal temperature, filter the reaction mixture and collect the filtrate, and analyze it with a high-performance liquid chromatography (HPLC). The calculated yield of the target product 5-ethoxymethylfurfural is 41.1%, wherein the amount of glucose added is 0.1mol / L, the amount of aluminum trifluoromethanesulfonate is 0.03mol / L, and the amount of ion exchange resin Amberlyst 15 is 10g / L.

Embodiment 3

[0024] Embodiment 3: This method utilizing glucose to prepare 5-ethoxymethylfurfural specifically comprises the following steps:

[0025] With glucose as the substrate, aluminum trifluoromethanesulfonate and ion exchange resin Amberlyst 15 as the co-catalyst, add to a stainless steel autoclave equipped with 6mL of absolute ethanol and 4mL of dimethyl sulfoxide, at an oil bath temperature of 140 °C React by magnetic stirring at a speed of 900r / min for 10h. After the reaction is completed, immediately immerse the reactor in cold water to cool down. After the temperature of the reactor drops to normal temperature, filter the reaction mixture and collect the filtrate, and analyze it with high-performance liquid chromatography (HPLC). The yield of the target product 5-ethoxymethylfurfural is calculated to be 38.5%, wherein the amount of glucose added is 0.05 mol / L, the amount of aluminum trifluoromethanesulfonate is 0.07 mol / L, and the amount of ion exchange resin Amberlyst 15 is 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com