Biological reaction chip and preparation method thereof

A biological reaction and chip technology, applied in the field of digital PCR biological detection, can solve the problems of complex process steps, high development cost, low sample loading rate, etc., and achieve the effects of simple process steps, improved reliability, and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

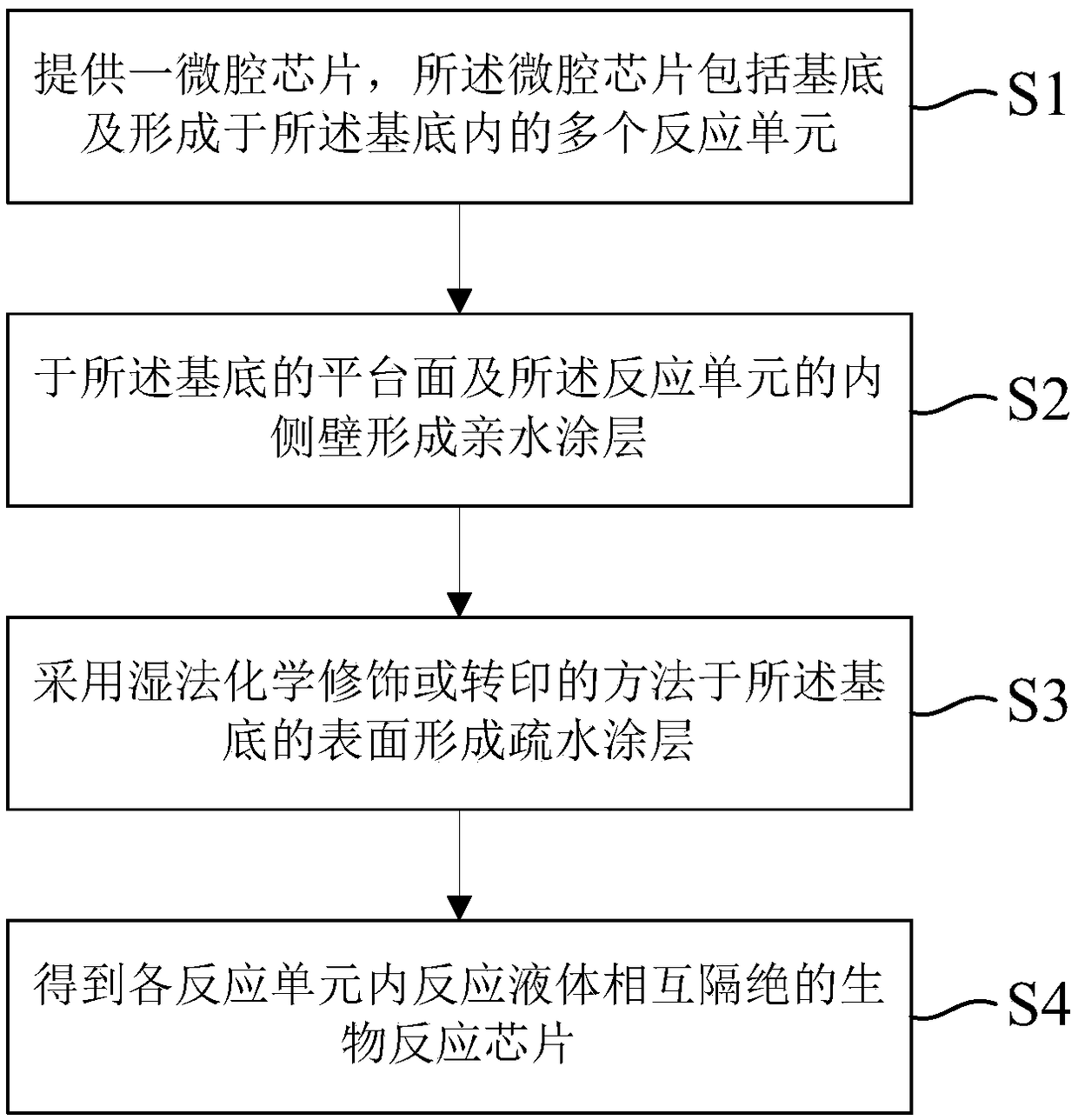

[0054] Such asfigure 1 As shown, the present invention provides a kind of preparation method of bioreactor chip, comprising:

[0055] Step S1: providing a microcavity chip, the microcavity chip includes a substrate and a plurality of reaction units formed in the substrate.

[0056] Step S2: forming a hydrophilic coating on the platform surface of the substrate and the inner wall of the reaction unit.

[0057] Step S3: forming a hydrophobic coating on the surface of the substrate by means of wet chemical modification or transfer printing.

[0058] Step S4: obtaining a bioreaction chip in which the reaction liquids in each reaction unit do not interfere with each other.

Embodiment 1

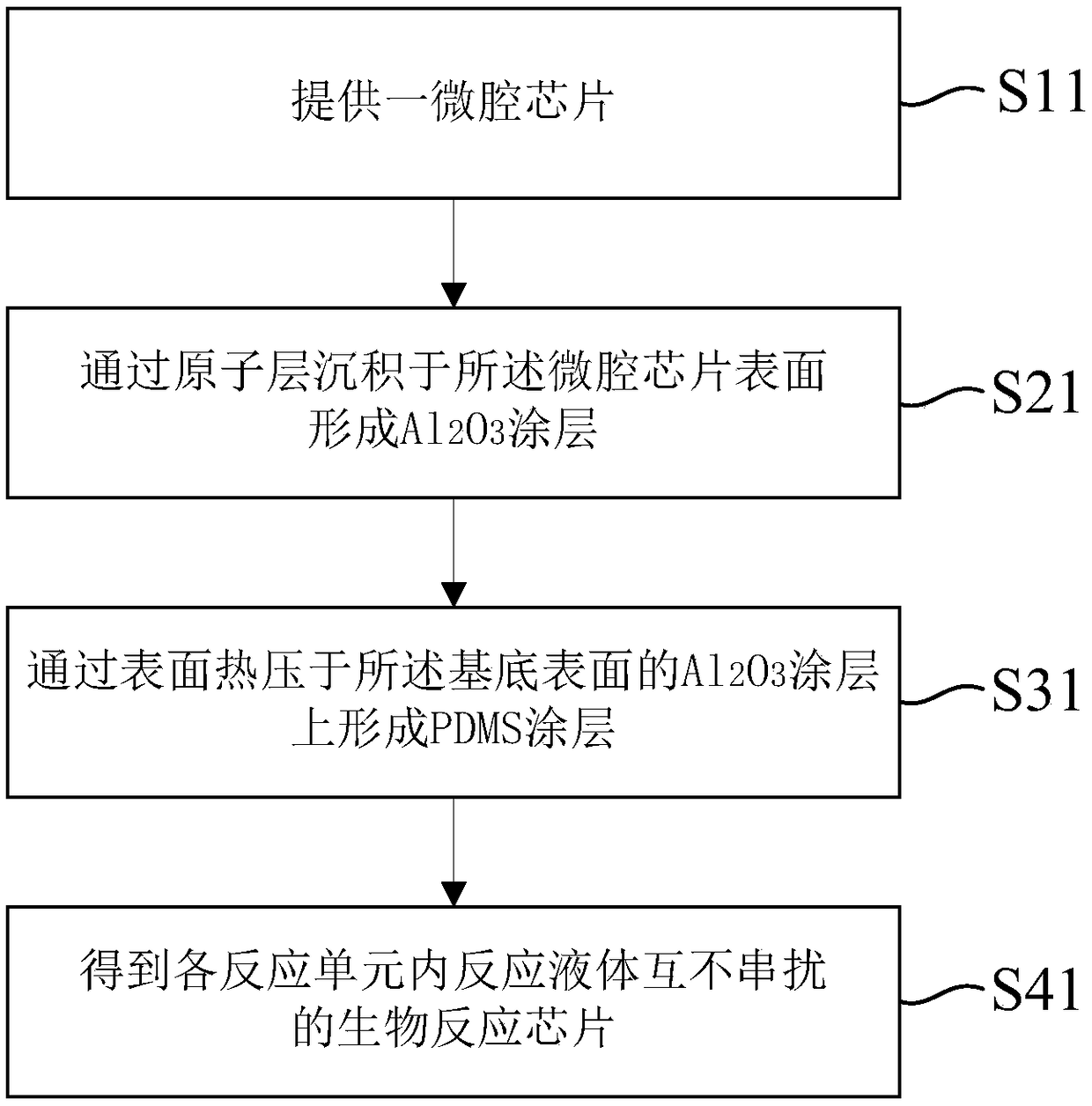

[0060] Such as figure 2 As shown, the present embodiment provides a method for preparing a bioreaction chip, and the method for preparing a bioreaction chip includes:

[0061] Step S11 : providing a microcavity chip 3 .

[0062] Specifically, the step of preparing the microcavity chip 3 includes:

[0063] Step S111: if image 3 As shown, a substrate 1 is provided, and the material of the substrate 1 includes but not limited to silicon, silicon oxide, glass, plastic and silica gel, and is not limited to this embodiment.

[0064] Step S112: if Figure 4 As shown, micro-holes are formed on the substrate 1 by micro-processing means such as photolithography and etching, and each micro-hole is used as a reaction unit 2 . In this example, 1cm 2 30,000 (or more than 30,000) micropores are formed on the substrate 1 to obtain high-density reaction units to ensure the reliability of calculation results. In practical applications, the density of micropores can be adjusted according ...

Embodiment 2

[0076] Such as Figure 7 As shown, the present invention provides a method for preparing a bioreaction chip. The difference from Example 1 is that the reaction unit 2 is a through hole, and the hydrophobic coating 5 is formed by wet chemical modification. Specifically include the following steps:

[0077] Step S12: providing a microcavity chip 3.

[0078] Specifically, such as Figure 8 As shown, a substrate 1 is provided, and micropores are formed on the substrate 1 by micro-processing means such as photolithography and etching, and each micropore is used as a reaction unit 2 . In this embodiment, the reaction unit 2 is a through hole. Other structures are similar to those in Embodiment 1, and will not be repeated here.

[0079] Step S22: forming Al on the surface of the microcavity chip 3 by atomic layer deposition 2 o 3 coating.

[0080] Specifically, such as Figure 9 As shown, in this embodiment, Al is formed on the platform surface of the substrate 1 and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com