Expansion joint multilayer combined type water stopping device of underground engineering and manufacturing method thereof

A technology of underground engineering and water-stop device, which is applied in water conservancy engineering, infrastructure engineering, artificial island and other directions to achieve the effect of reducing spacing, reducing the loss rate of steel raw materials, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

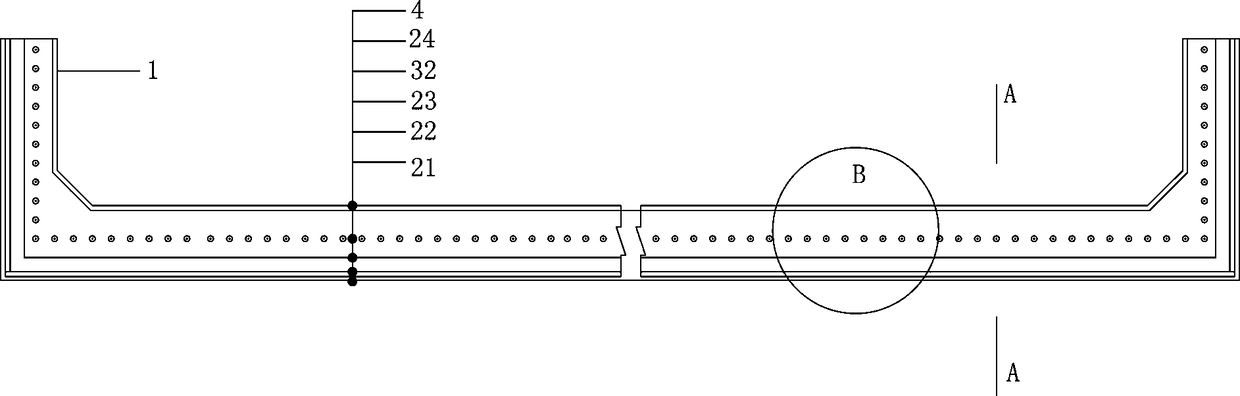

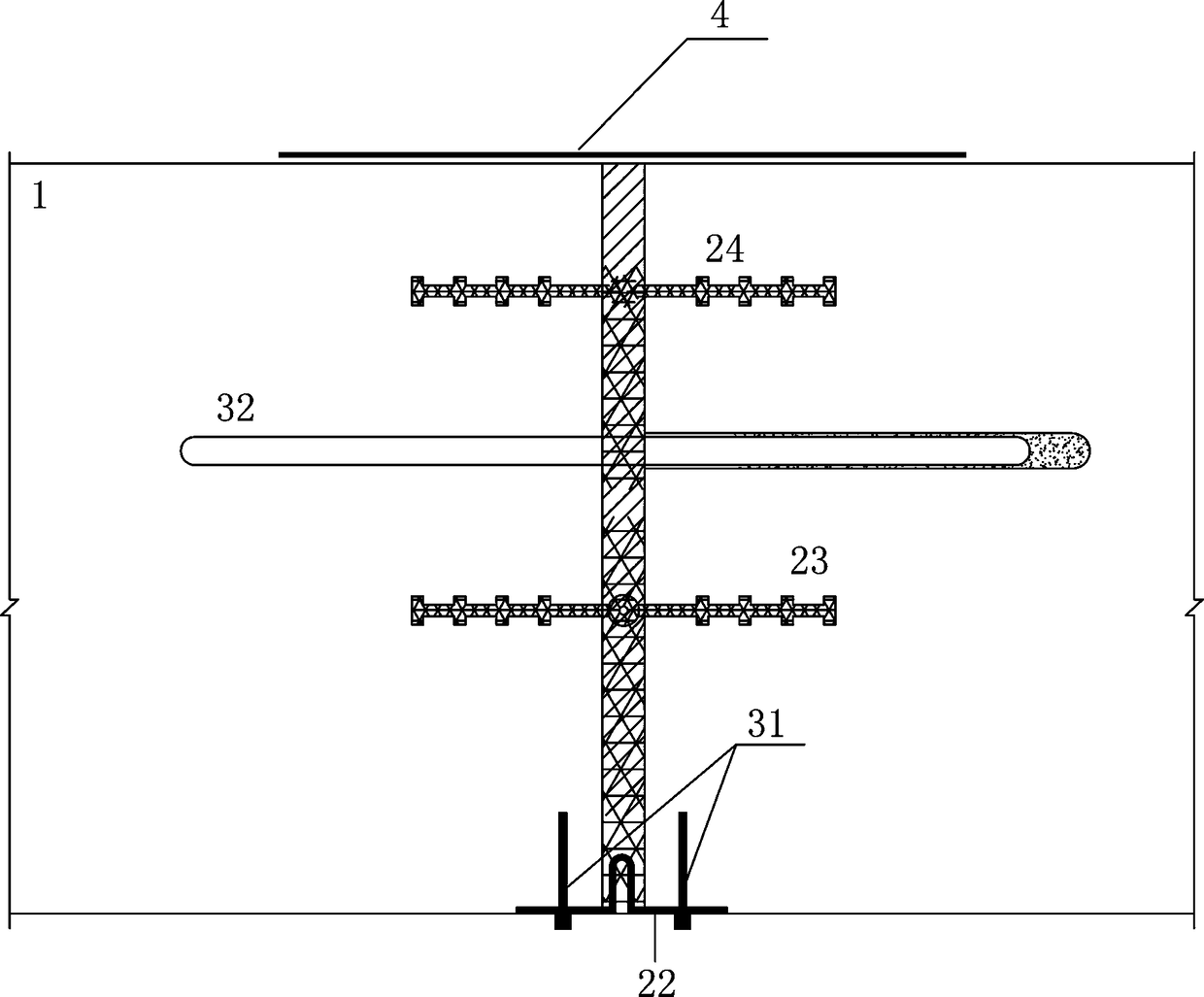

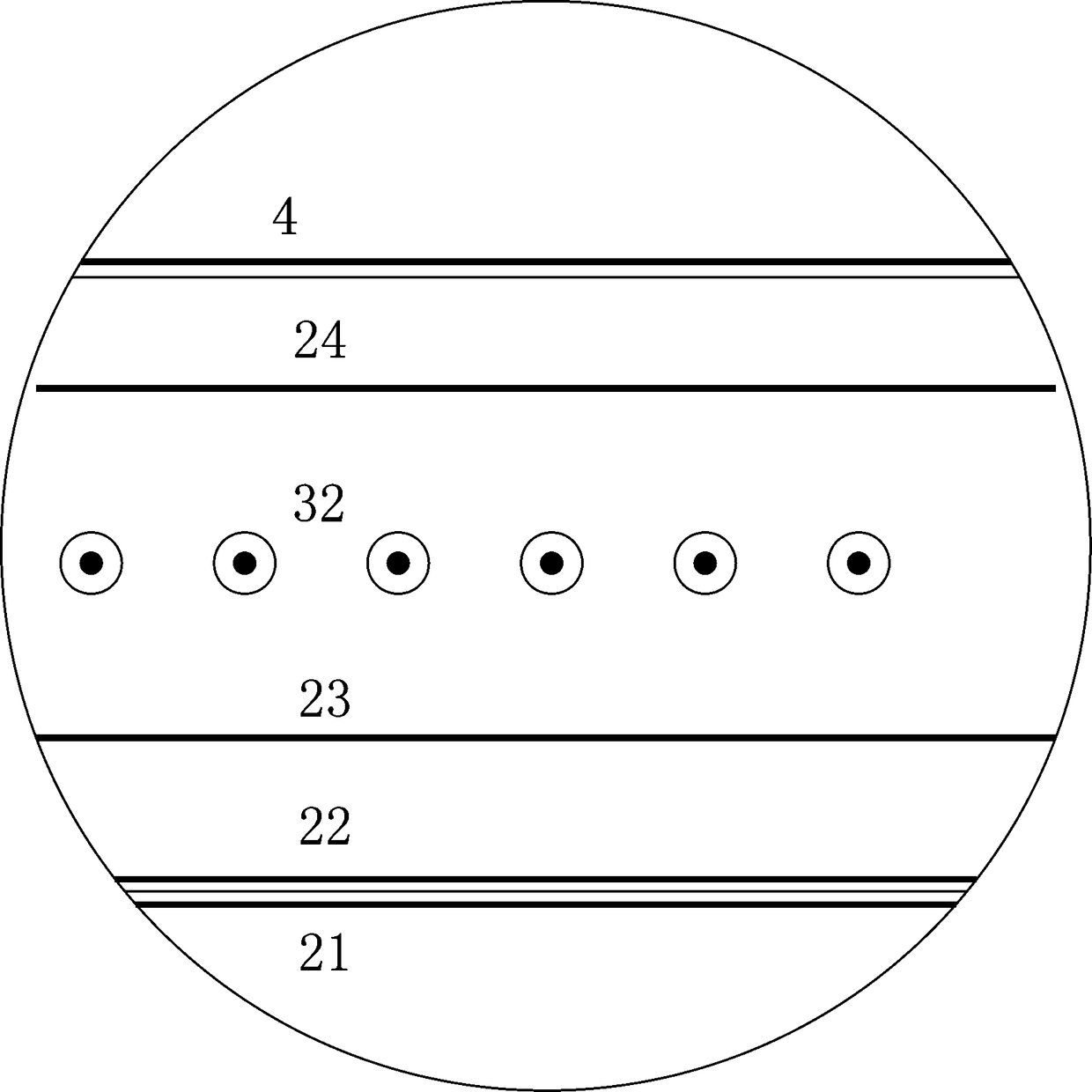

[0038] A multi-layer combined water stop device for expansion joints in underground engineering, including a wall body 1, a reverse-adhesive self-adhesive waterproof coiled material 21, a metal water stop belt 22, a rubber water stop belt 23, a steel edge rubber water stop belt 24, a tight Solid bolt 31, steel shear pin 32 and waterproofing agent 4, as Figure 1 ~ Figure 3 As shown, the specific structure is:

[0039] Reverse self-adhesive waterproof membrane 21, metal waterstop 22, rubber waterstop 23 and steel-edged rubber waterstop 24 are applied sequentially from outside to inside, reverse-pasted self-adhesive waterproof membrane 21, metal waterstop The belt 22 and the rubber waterstop 23 are connected and fastened by fastening bolts 31, and the steel edge surface of the steel edge rubber waterstop 24 and the rubber waterstop 23 are pasted and fixed on the wall 1 by the steel shear pin 32. Above, the rubber surface of the steel edge rubber waterstop 24 is coated with wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com