Seawater-resistant semiconductive water stopping strapping tape and preparation method thereof

A semi-conductive and seawater-resistant technology, which is applied in the manufacture of conductive/semiconductive layer equipment, submarine cables, cable/conductor manufacturing, etc. It can solve the problem that binding tapes do not have seawater resistance, water molecules spread, and fibers are easy to age And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

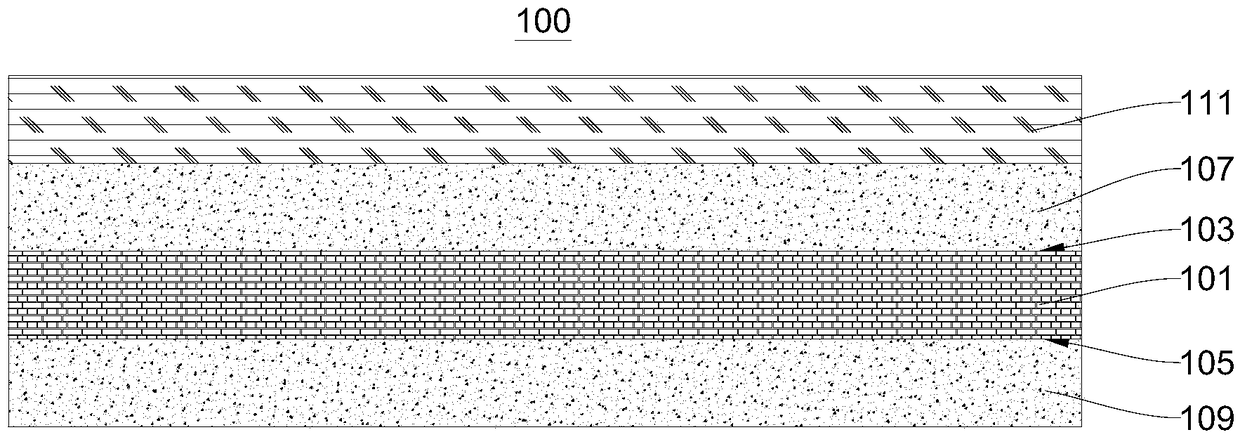

[0042] figure 1 A schematic structural diagram of the seawater-resistant semi-conductive water-stop binding tape 100 provided in this embodiment. see figure 1, This embodiment provides a seawater-resistant semiconductive water-stop binding tape 100 , including: a base material layer 101 , a first semiconductive adhesive layer 107 , a second semiconductive adhesive layer 109 and a semiconductive seawater-resistant adhesive layer 111 . Wherein, the substrate layer 101 has a first surface 103 and a second surface 105 oppositely arranged; the first semiconductive adhesive layer 107 is arranged on the first surface 103 of the substrate layer 101; the second semiconductive adhesive layer 109 is arranged on the substrate The second side 105 of the layer 101 . The semiconductive seawater resistant adhesive layer 111 is disposed above the first semiconductive adhesive layer 107 . The seawater-resistant semi-conductive water-stop binding tape 100 has good electric field shielding and...

Embodiment 2

[0055] This embodiment provides a method for preparing a seawater-resistant semi-conductive water-stop binding tape 100, which differs from the preparation method of the sea-water-resistant semi-conductive water-stop binding tape 100 provided in Example 1 in that in this embodiment:

[0056] The first semiconductive adhesive layer 107 and the second semiconductive adhesive layer 109 are mainly made from the following raw materials in parts by weight: 50 parts of textile emulsion, 12 parts of carbon black, 8 parts of dispersant, 0.8 part of wetting agent and 450 parts of water.

[0057] And, in this embodiment, in the process of disposing the first semiconductive adhesive layer 107 on the first surface 103 of the substrate layer 101, and disposing the second semiconductive adhesive layer 109 on the second surface 105 of the substrate layer 101 Among them, the linear speed of glue processing is 30m / min; and the semiconductive seawater resistant adhesive layer 111 is arranged on ...

Embodiment 3

[0060] This embodiment provides a method for preparing a seawater-resistant semi-conductive water-stop binding tape 100, which differs from the preparation method of the sea-water-resistant semi-conductive water-stop binding tape 100 provided in Example 1 in that in this embodiment:

[0061] The first semiconductive adhesive layer 107 and the second semiconductive adhesive layer 109 are mainly made from the following raw materials in parts by weight: 80 parts of textile emulsion, 15 parts of carbon black, 10 parts of dispersant, 1 part of wetting agent and 500 parts of water.

[0062] And, in this embodiment, in the process of disposing the first semiconductive adhesive layer 107 on the first surface 103 of the substrate layer 101, and disposing the second semiconductive adhesive layer 109 on the second surface 105 of the substrate layer 101 Among them, the linear speed of glue processing is 50m / min; and the semiconductive seawater resistant adhesive layer 111 is arranged on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com