PCB underwater wire repairing device

An equipment and wire repair technology, applied in the field of PCB underwater repair wire equipment, can solve the problems of increasing the difficulty of repairing wires, peeling of copper foil and insulating substrate, limited connection strength between copper foil and insulating substrate, etc., to achieve good heat conduction and heat dissipation. , cost saving, and the effect of improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and technical effect of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

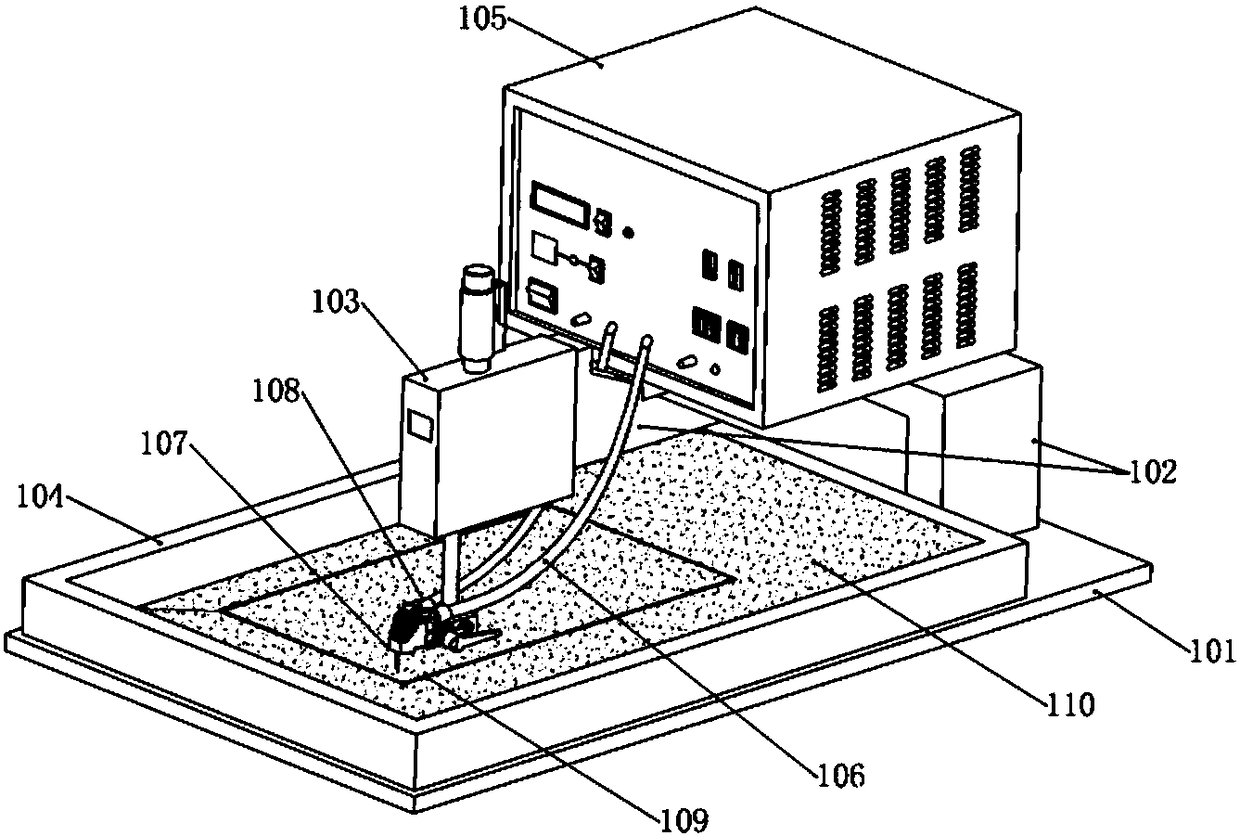

[0015] Please refer to figure 1 As shown, it is a structural schematic diagram of the PCB underwater patching equipment of the present invention, which includes a workbench 101, a head support 102, a spot welding head 103, a workpiece water tray 104 for placing a PCB, and a resistance welding welding power supply 105, wherein, The spot welding head 103 is installed on the head support 102, the workpiece water tray 104 is placed on the workbench 101 below the spot welding head 103, and the resistance welding welding power supply 105 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com