Flue gas treatment system and technology for TFT glass kiln

A technology of flue gas treatment system and glass kiln, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of high energy consumption, large water consumption, long treatment cycle, etc., and reduce treatment costs , Reduce equipment investment and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention is explained and illustrated in detail below.

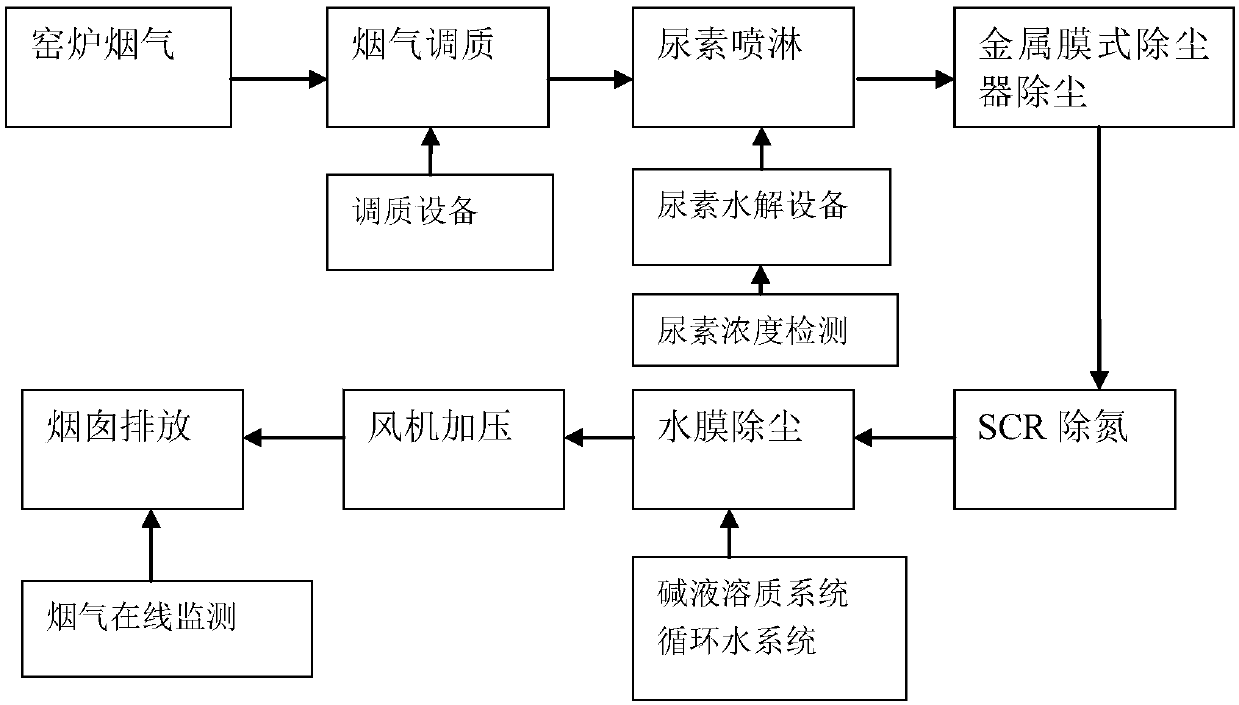

[0023] The kiln flue gas is processed through the following processes in turn, kiln flue gas - flue gas conditioning (flue gas conditioning equipment) - urea spraying (urea hydrolysis and dissolution system, urea concentration detection and feedback to DCS) - metal membrane dust collector —SCR system—water film dedusting (Pall ring)—fan pressurization—chimney discharge.

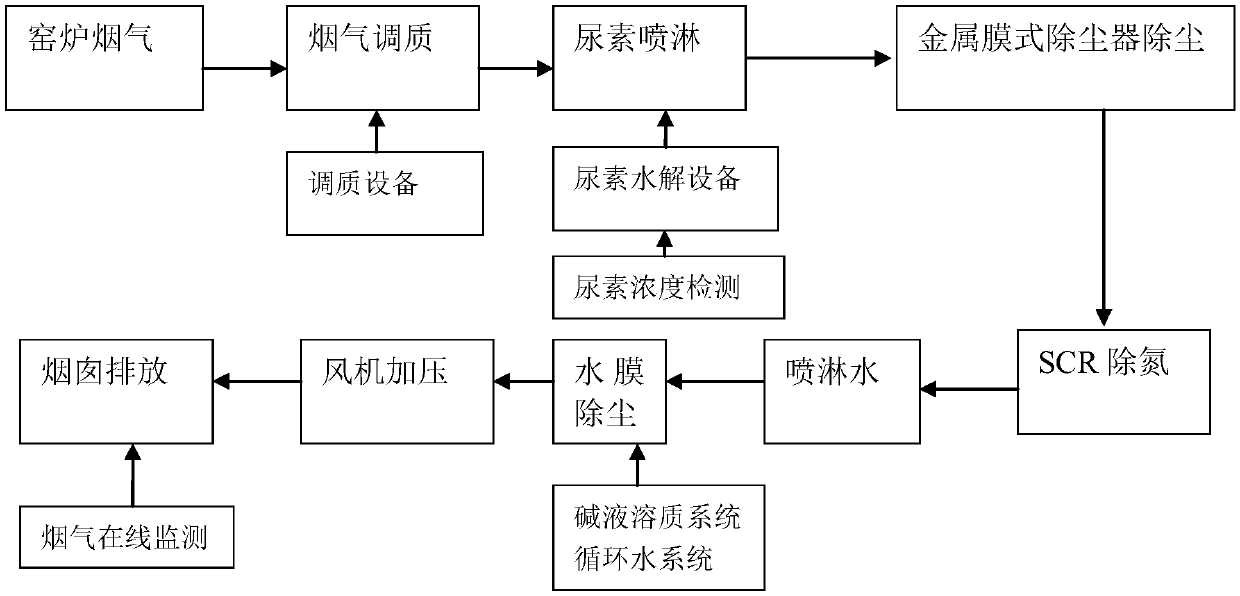

[0024] As another embodiment of the present invention, such as figure 2 As shown, the kiln flue gas is processed through the following process in turn, kiln flue gas - flue gas conditioning (flue gas conditioning equipment) - urea spraying (urea hydrolysis and dissolution system, urea concentration detection and feedback to DCS) - metal film Type dust collector—SCR system—spray water—water film dedusting (Pall ring)—fan pressurization—chimney discharge; in the flue, the flue gas is sprayed with water to dissolve the unreacted ammonia gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com