Metal casting blank continuous manufacturing device and method capable of providing pressure casting

A manufacturing device and metal technology, which is applied in the field of continuous manufacturing devices for metal billets that can provide pressure casting, can solve the problems affecting the quality of billets and the inability to effectively control the melting temperature, etc., achieve continuous preparation, improve the quality of molten iron, and increase the use of The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

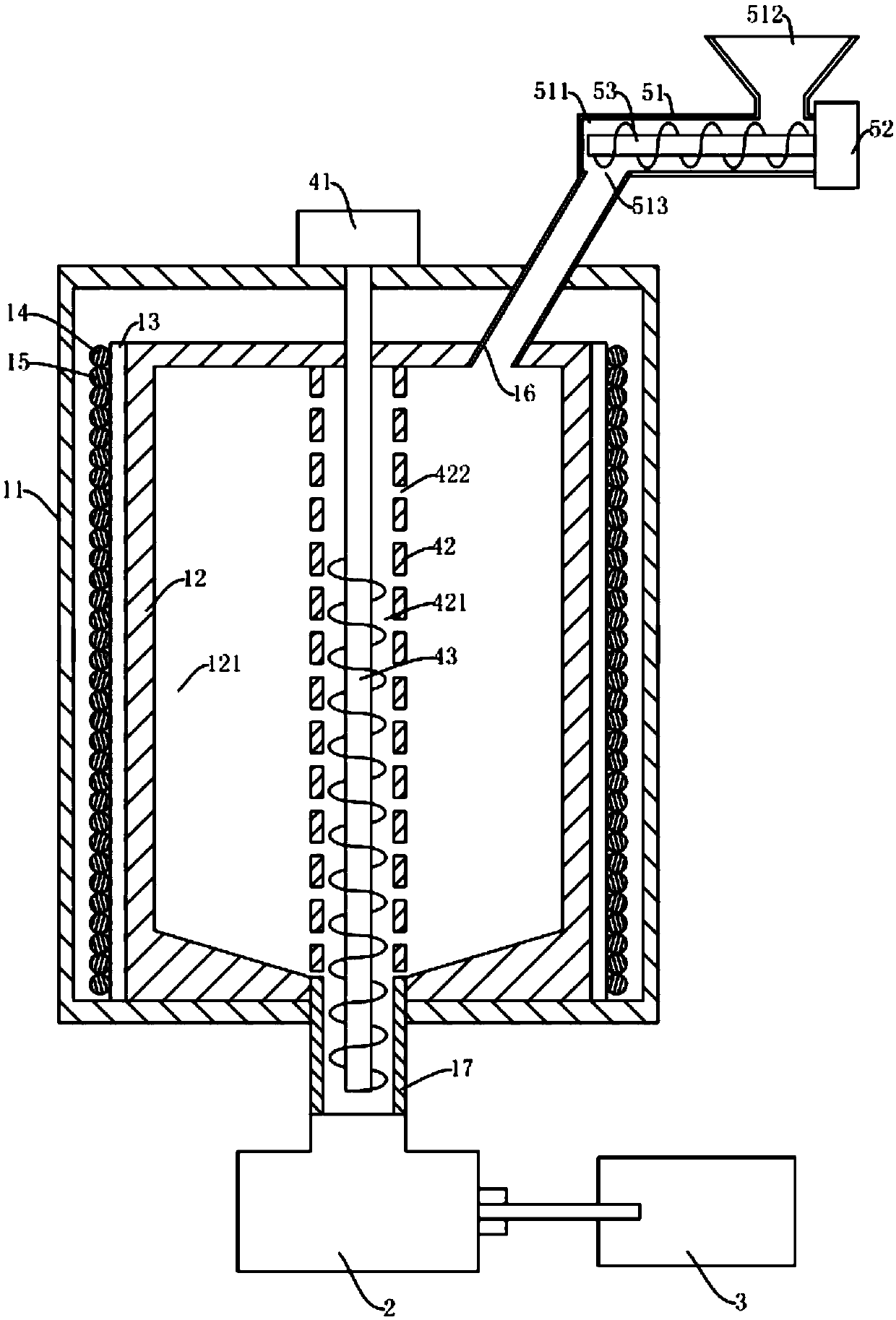

[0062] A method for continuously manufacturing aluminum alloy rod blanks with a diameter of 8 mm. First, the electromagnetic heating controller is started to preheat the crucible 12 for 10 minutes, and the temperature in the melting chamber 121 is monitored by a temperature sensor until the temperature in the melting chamber 121 reaches 500° C.; the feeding motor 52 and the propeller 53 are started. Turn the material in the material tank 512 into the melting chamber 121 through the feeding pipe 16, control the electromagnetic heating controller to increase the output power until the temperature in the melting chamber 121 reaches 1500 °C; half an hour later, start the propulsion motor 41 and crystallization Device 2, control the rotational speed of the screw rod 43 to less than 10r / min, start the traction mechanism to pull the aluminum alloy rod, and control the continuous or intermittent movement of the feeding motor 52 at the same time, so as to realize the continuous feeding o...

Embodiment 2

[0064] A continuous manufacturing method for a copper alloy rod billet with a diameter of 16 mm. Firstly, the electromagnetic heating controller is started to preheat the crucible 12 for 20 minutes, and the temperature in the melting chamber 121 is monitored by a temperature sensor until the temperature in the melting chamber 121 reaches 800° C.; the feeding motor 52 and the propeller 53 are started. Turn the material in the material tank 512 into the melting chamber 121 through the feeding pipe 16, control the electromagnetic heating controller to increase the output power until the temperature in the melting chamber 121 reaches 1800 °C; half an hour later, start the propulsion motor 41 and the crystallizer Device 2, control the rotating speed of the screw rod 43 to 15r / min, start the traction mechanism to pull the copper alloy rod, and control the continuous or intermittent movement of the feeding motor 52 at the same time, to realize the continuous feeding or intermittent fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com