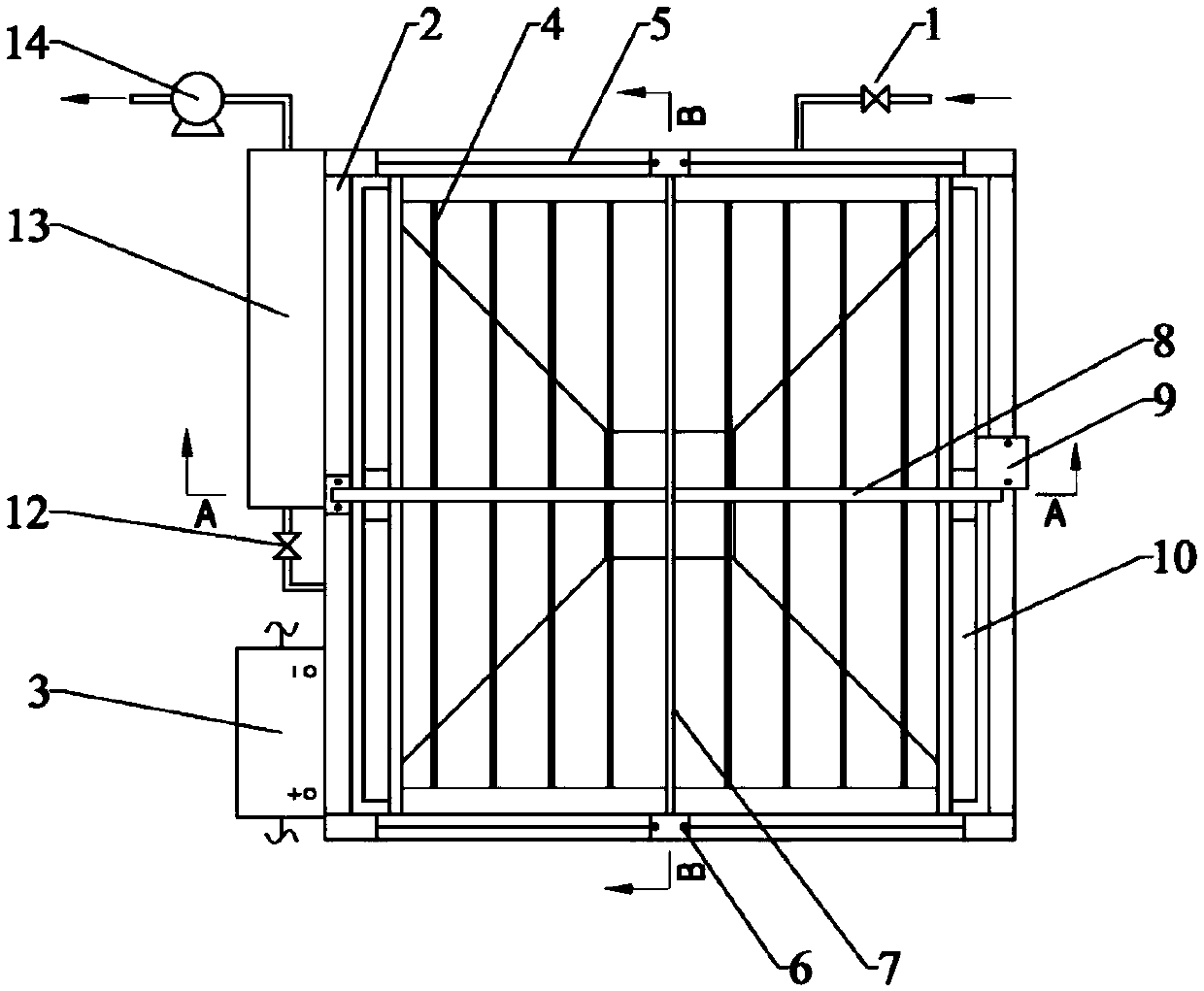

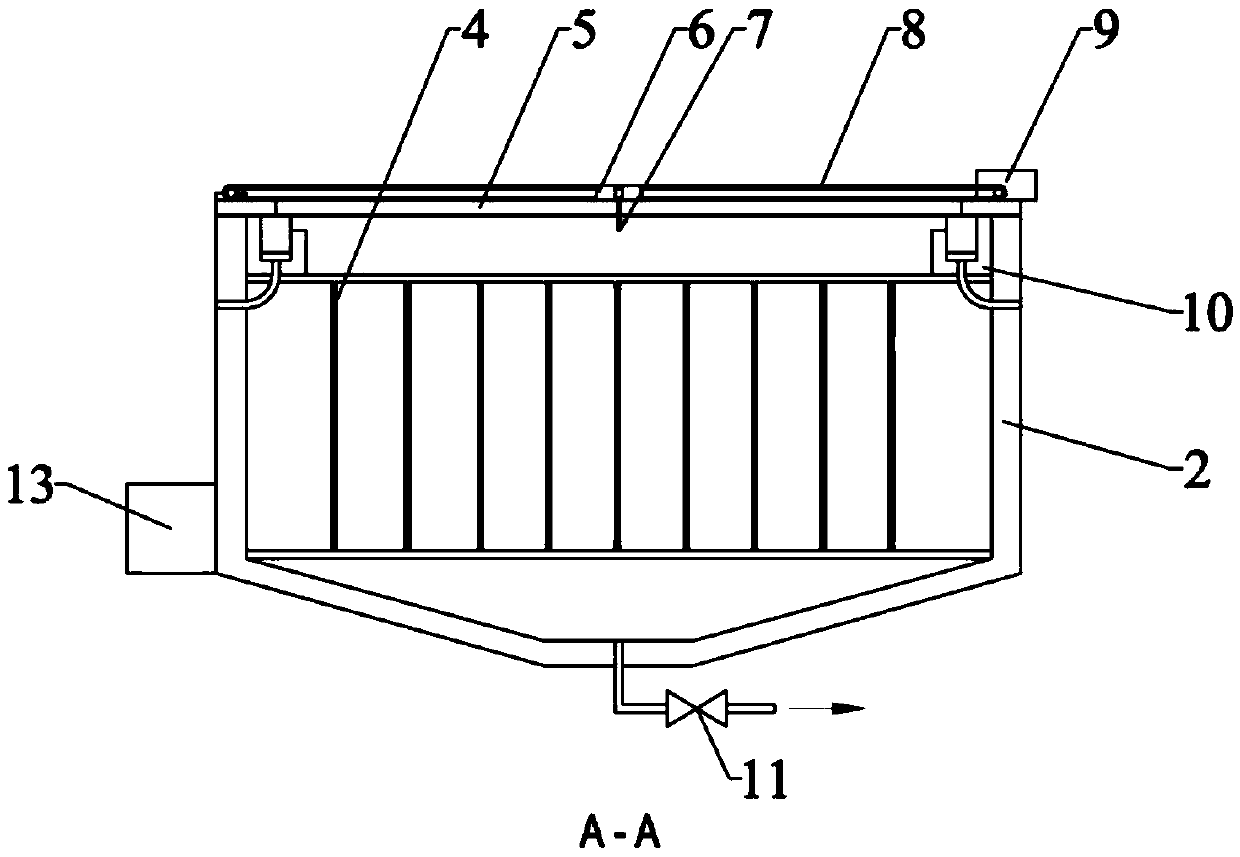

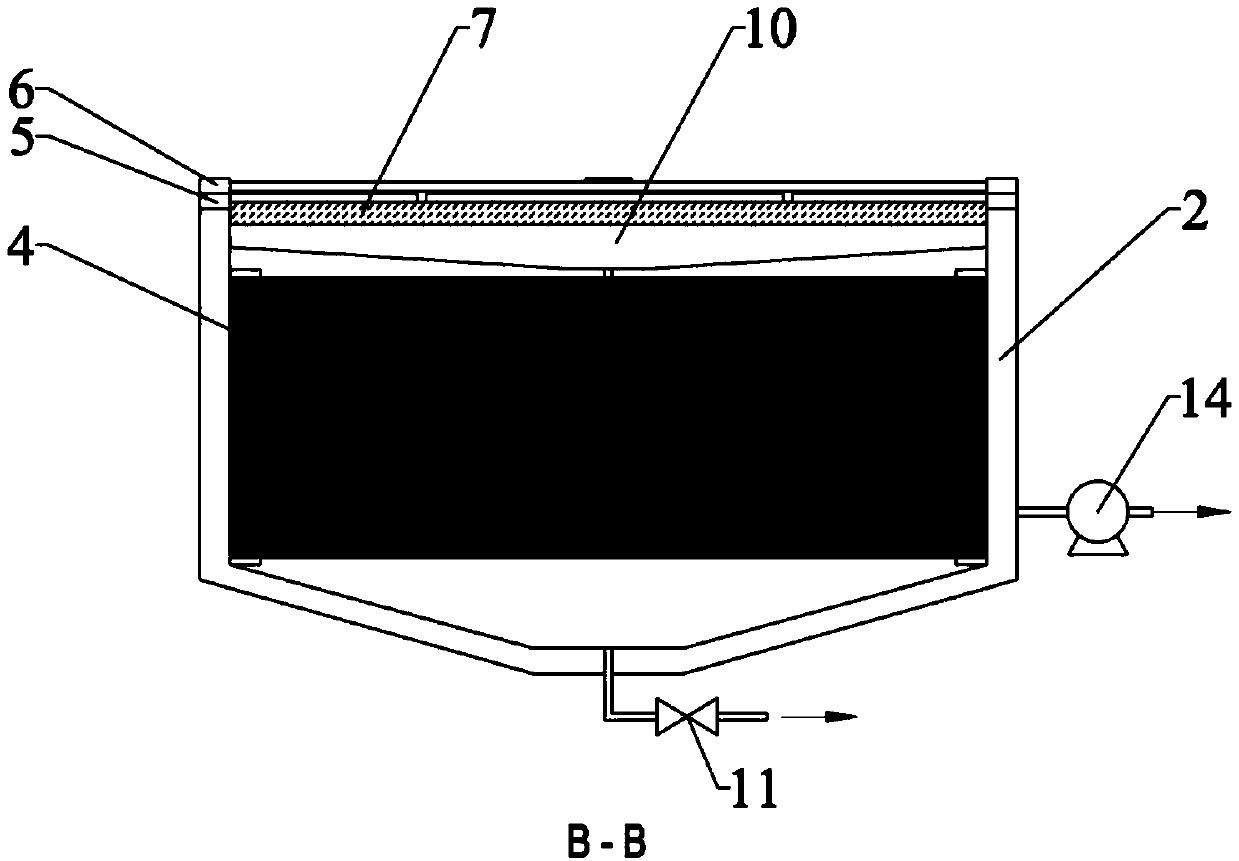

Three-dimensional pulse type electrochemical laundry wastewater reuse device

A three-dimensional electrode, pulsed technology, applied in chemical instruments and methods, gray water treatment, water/sewage treatment, etc., can solve the problems of anode plate loss increasing equipment cost, oxide film reducing treatment efficiency, etc., to improve power utilization efficiency, alleviating electrode passivation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Tap water, household clothes and common washing powder were used to make water samples. The turbidity of sewage was 110 NTU, and the content of anionic surfactant was 297.24 mg / L. After being treated by the device of the present invention for 15 minutes, the content of residual anionic surfactant was 3.6 mg / L. L, the removal rate was 98.8%, and the turbidity was 2.3 NTU.

Embodiment 2

[0033] Water samples were prepared using tap water, household clothes and common laundry detergent. The turbidity of sewage was 85.8 NTU, and the content of anionic surfactant was 238.8 mg / L. After being treated by the device of the present invention for 15 minutes, the content of residual anionic surfactant was 9.2 mg / L. L, the removal rate was 96%, and the turbidity was 4 NTU.

Embodiment 3

[0035] According to "GB T4288-2008 Household and Similar Electric Washing Machines", water samples were prepared with contaminated cloth and detergent. The sewage turbidity was 91 NTU, and the content of anionic surfactant was 273 mg / L. The device of the present invention was used to treat it for 15 minutes After that, the residual anionic surfactant content was 1.68 mg / L, the removal rate was 99.4%, and the turbidity was 3.2 NTU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com