Method for preparing magnetic field driven intelligent flexible material

A flexible material and magnetic field-driven technology, applied in the field of materials, can solve the problems of complex preparation process of magnetically responsive flexible materials, constraints of magnetic response rate and mechanical strength, high preparation cost, etc., to improve convenience, fast magnetic response speed, and preparation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

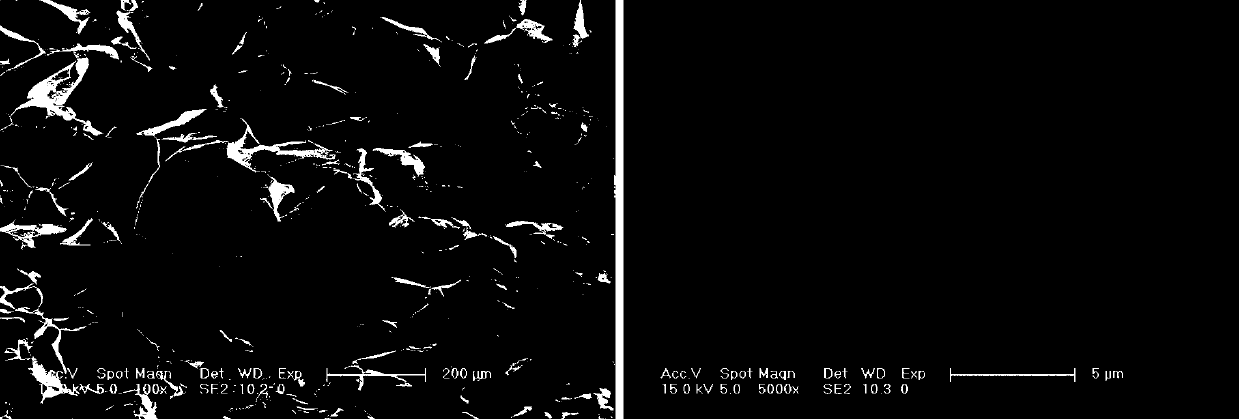

[0018] See how figure 1 As shown, the preparation of Fe 3 o 4 Magnetic field driven intelligent deformable material with nanoparticle content of 10mg / mL

[0019] Choose N,N-dimethylacrylamide as monomer, XLS-type synthetic magnesium lithium silicate as crosslinking agent, potassium persulfate as initiator, and N,N,N',N'-tetramethylethylenediamine as Catalyst, nano-wood pulp cellulose as reinforcing phase, Fe 3 o 4 Nanoparticles serve as the magnetically responsive phase. The molar ratio between monomer, initiator and catalyst is 100:0.370:0.638; the concentration of nano-wood pulp cellulose is 3mg / mL~5mg / mL, Fe 3 o 4 The concentration of nanoparticles is 10mg / mL, the mass fraction of cross-linking agent is 3wt.%~3.5wt.%, the Fe 3 o 4 Add nanoparticles to distilled water for 10-15 minutes of ultrasonic vibration, then stir for 25-30 minutes, then add nano-wood pulp cellulose, and stir for 30-40 minutes, then ultrasonically treat for 10-15 minutes; then add XLS type synt...

Embodiment 2

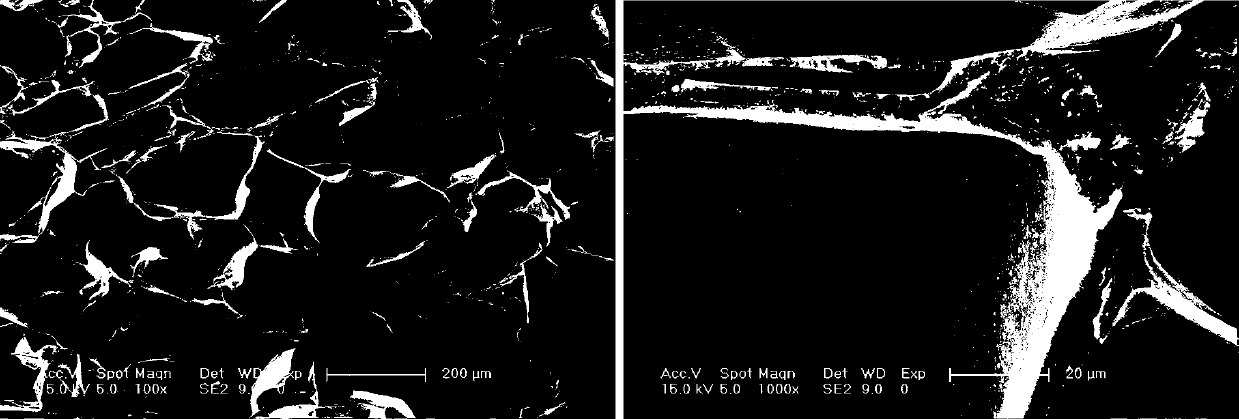

[0021] See how figure 2 As shown, Fe 3 o 4 Magnetic field-driven smart deformable material with nanoparticle content of 30 mg / mL

[0022] Choose N,N-dimethylacrylamide as monomer, XLS-type synthetic magnesium lithium silicate as crosslinking agent, potassium persulfate as initiator, and N,N,N',N'-tetramethylethylenediamine as Catalyst, nano-wood pulp cellulose as reinforcing phase, Fe3O4 nanoparticles as magnetic response phase, the molar ratio between monomer, initiator and catalyst is 100:0.370:0.638; the concentration of nano-wood pulp cellulose is 3mg / mL~ 5mg / mL, Fe 3 o 4 The concentration of nanoparticles is 30mg / mL, the mass fraction of cross-linking agent is 3wt.%~3.5wt.%, the Fe 3 o 4 Add nanoparticles to distilled water for 10-15 minutes of ultrasonic vibration, then stir for 25-30 minutes, then add nano-wood pulp cellulose, and stir for 30-40 minutes, then ultrasonically treat for 10-15 minutes; then add XLS type synthetic silicic acid Magnesium lithium, stir...

Embodiment 3

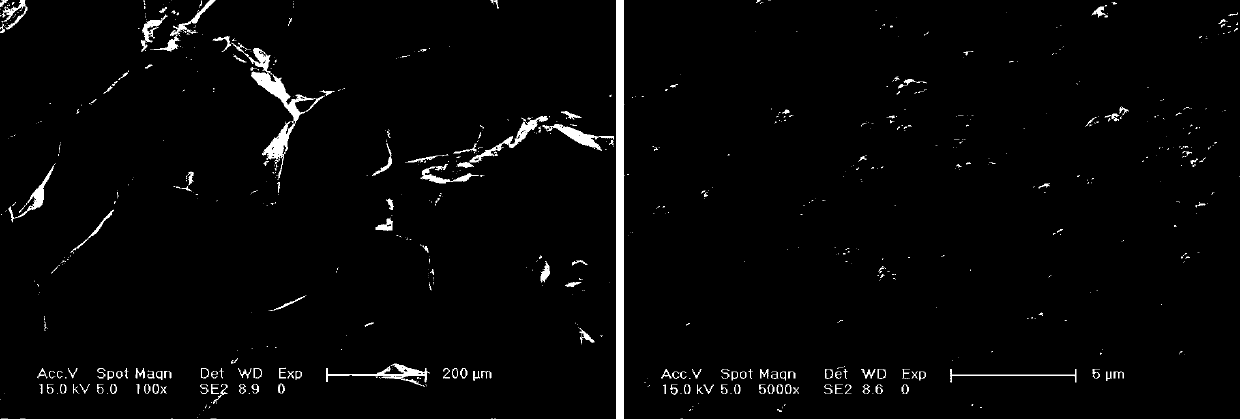

[0024] See how image 3 and Figure 4 As shown, Fe 3 o 4 Magnetic field driven intelligent deformable material with nanoparticle content of 50 mg / mL

[0025] Choose N,N-dimethylacrylamide as monomer, XLS-type synthetic magnesium lithium silicate as crosslinking agent, potassium persulfate as initiator, and N,N,N',N'-tetramethylethylenediamine as Catalyst, nano-wood pulp cellulose as reinforcing phase, Fe 3 o 4 Nanoparticles serve as the magnetically responsive phase. The molar ratio between monomer, initiator and catalyst is 100:0.370:0.638; the concentration of nano-wood pulp cellulose is 3mg / mL~5mg / mL, Fe 3 o 4 The concentration of nanoparticles is 50mg / mL, the mass fraction of cross-linking agent is 3wt.%~3.5wt.%, the Fe 3 o 4Add nanoparticles to distilled water for 10-15 minutes of ultrasonic vibration, then stir for 25-30 minutes, then add nano-wood pulp cellulose, and stir for 30-40 minutes, then ultrasonically treat for 10-15 minutes; then add XLS type syntheti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com