A kind of waterproof and moisture-permeable aqueous polyurethane dispersion and its preparation method and application

A water-based polyurethane, waterproof and moisture-permeable technology, which is applied in polyurea/polyurethane coatings, textiles, papermaking, coatings, etc., can solve the problems of water pressure resistance, resin water pressure resistance, and performance. Simple operation and production process, and the effect of improving moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Add 40g of HMDI, 25.2g HDI, 70g N120, 35g PPG2000, 50gPTMEG2000, 15gPTMEG1000, 30gMN3050, after reacting at 80°C for 1h, reached a theoretical NCO% of 6.13%.

[0079] Cool down to 60°C, add 6g BDO, 0.08136g catalyst 8108 and 40g acetone to dilute, stir evenly, heat up to 80°C, react for 4.5-6.5h (start timing at 75°C), and stop the reaction when the theoretical NCO% reaches 2.51%. Cool down to 60°C, add 54g of acetone to dilute, stir and mix for 5 minutes to fully mix the prepolymer and acetone, and continue to cool down to 30-35°C.

[0080] Add 1010 / 292 acetone solution, stir for 5 minutes to make the mixture uniform, stir at 1200-1500 rpm, add 656g of deionized water within 6 minutes.

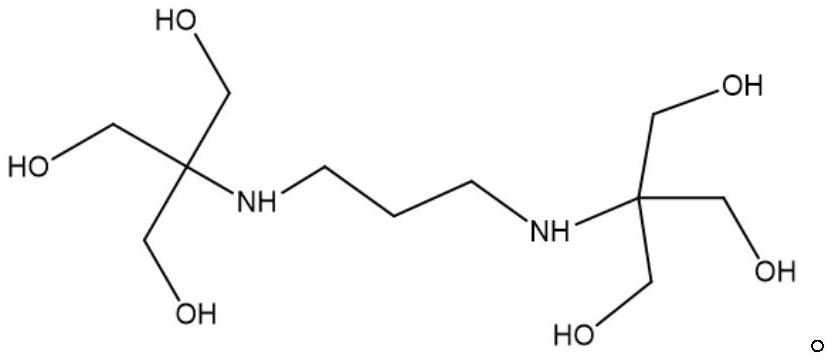

[0081] Dilute 2g of ethylenediamine and 10g of 1,3-bis[(trimethylol)methylamino]propane with 48g of deionized water, slowly add to the system, react at a constant temperature of 35°C for 5min, and distill the prepared emulsion under reduced pressure Acetone was removed to obtain a...

Embodiment 2

[0083] Add 41g HMDI, 25g HDI, 60g N120, 36g PPG2000, 47gPTMEG2000, 17gPTMEG1000, 30gMN3050, after reacting at 85°C for 1h, reached a theoretical NCO% of 6.53%.

[0084] Cool down to 60°C, add 7g of BDO, 0.0789g of catalyst 8108 and 39.6g of acetone to dilute, stir evenly, heat up to 85°C, react for 4.5-6.5h (start timing at 75°C), and stop the reaction when the theoretical NCO% reaches 2.61%. Cool down to 60°C, add 52.6g of acetone to dilute, stir and mix for 5 minutes to fully mix the prepolymer and acetone, and continue to cool down to 30-35°C.

[0085] Add 1010 / 292 acetone solution, stir for 5 minutes to make the mixture uniform, stir at 1200-1500 rpm, add 637g of deionized water within 6 minutes to obtain a water-based polyurethane dispersion.

[0086] Dilute 2g of ethylenediamine and 10g of 1,3-bis[(trimethylol)methylamino]propane with 48g of deionized water, slowly add to the system, react at a constant temperature of 35°C for 5min, and distill the prepared emulsion ...

Embodiment 3

[0088] Add 38g HMDI, 24g HDI, 80g N120, 50g PPG2000, 60gPTMEG2000, 15gPTMEG1000, 38gMN3050, after reacting at 75°C for 1h, reached a theoretical NCO% of 4.41%.

[0089] Cool down to 60°C, add 3.5g of BDO, 0.09255g of catalyst 8108 and 46g of acetone to dilute, stir evenly, heat up to 75°C, react for 4.5-6.5h (start timing at 75°C), and stop the reaction when the theoretical NCO% reaches 1.89%. Cool down to 60°C, add 61g of acetone to dilute, stir and mix for 5 minutes to fully mix the prepolymer and acetone, and continue to cool down to 30-35°C.

[0090] Add 1010 / 292 acetone solution, stir for 5 minutes to make the mixture uniform, stir at 1200-1500 rpm, add 730 g of deionized water within 6 minutes to obtain a water-based polyurethane dispersion.

[0091] Dilute 4g of isophoronediamine and 10g of 1,3-bis[(trimethylol)methylamino]propane with 56g of deionized water, slowly add to the system, and react at a constant temperature of 35°C for 5min, and the prepared emulsion T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com