Method for improving extraction rate of valeriana officinalis essential oil

A technology of valerian essential oil and extraction rate, which is applied in the direction of essential oil/fragrance, fat production, etc., to achieve the effect of easy extraction, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

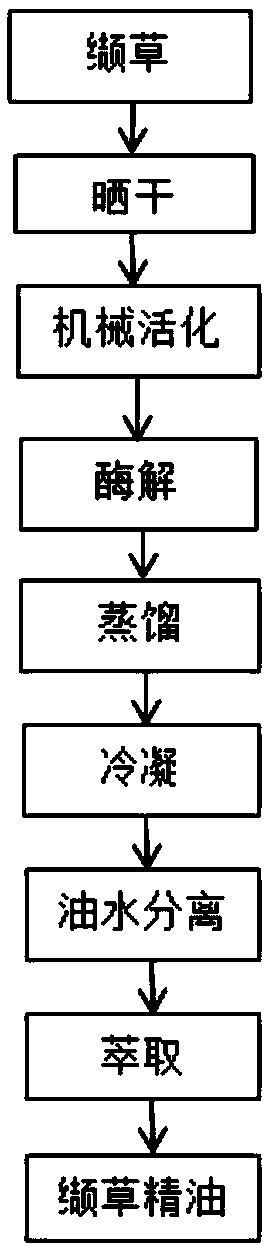

[0027] A method for improving the extraction rate of valerian essential oil, the steps are as follows:

[0028] (1) the valerian root of gathering is dried, and its moisture content is 8.5%;

[0029] (2) mechanical activation: add the dried valerian root in the stirring ball mill, and mechanically activate it for 7 minutes at a rotating speed of 90r / min to obtain the valerian root powder;

[0030] (3) Enzymolysis treatment: use compound enzyme to treat valerian root powder at 45°C for 2.5 hours;

[0031] (4) Distillation: feed water vapor from the bottom of the retort to heat the extract, and extract for 2 hours after the extract boils to obtain mixed steam;

[0032] (5) Condensation: the mixed steam obtained above is condensed through a condenser, and the oil-water mixture is obtained after condensation;

[0033] (6) oil-water separation: the oil-water mixture obtained by condensation is carried out oil-water separation through the oil-water separator to obtain valerian cru...

Embodiment 2

[0036] A method for improving the extraction rate of valerian essential oil, the steps are as follows:

[0037] (1) the valerian root of gathering is dried, and its moisture content is 10%;

[0038] (2) mechanical activation: add the dried valerian root in the stirring ball mill, and mechanically activate it for 5 min at a rotating speed of 100r / min to obtain the valerian root powder;

[0039] (3) Enzymolysis treatment: use compound enzyme to treat valerian root powder at 45°C for 2.5 hours;

[0040] (4) Distillation: feed water vapor from the bottom of the retort to heat the extract, and extract for 2 hours after the extract boils to obtain mixed steam;

[0041] (5) Condensation: the mixed steam obtained above is condensed through a condenser, and the oil-water mixture is obtained after condensation;

[0042] (6) oil-water separation: the oil-water mixture obtained by condensation is carried out oil-water separation through the oil-water separator to obtain valerian crude o...

Embodiment 3

[0045] A method for improving the extraction rate of valerian essential oil, the steps are as follows:

[0046] (1) the valerian root of gathering is dried, and its moisture content is 12%;

[0047] (2) mechanical activation: add the dried valerian root in the stirring ball mill, and mechanically activate it for 5 min at a rotating speed of 110r / min to obtain the valerian root powder;

[0048] (3) Enzymolysis treatment: use compound enzyme to treat valerian root powder at 50°C for 3 hours;

[0049] (4) Distillation: feed water vapor from the bottom of the retort to heat the extract, extract after boiling for 2.5 hours to obtain mixed steam;

[0050] (5) Condensation: the mixed steam obtained above is condensed through a condenser, and the oil-water mixture is obtained after condensation;

[0051] (6) oil-water separation: the oil-water mixture obtained by condensation is carried out oil-water separation through the oil-water separator to obtain valerian crude oil and water; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com