A kind of preparation method of bearing steel produced by converter process

A bearing steel and converter technology, applied in the manufacture of converters, etc., can solve the problems of steel properties that are difficult to meet strict standards and uneven distribution of non-metallic inclusions, so as to achieve uniform mold slag layer, promote full flotation, and meet lubrication requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

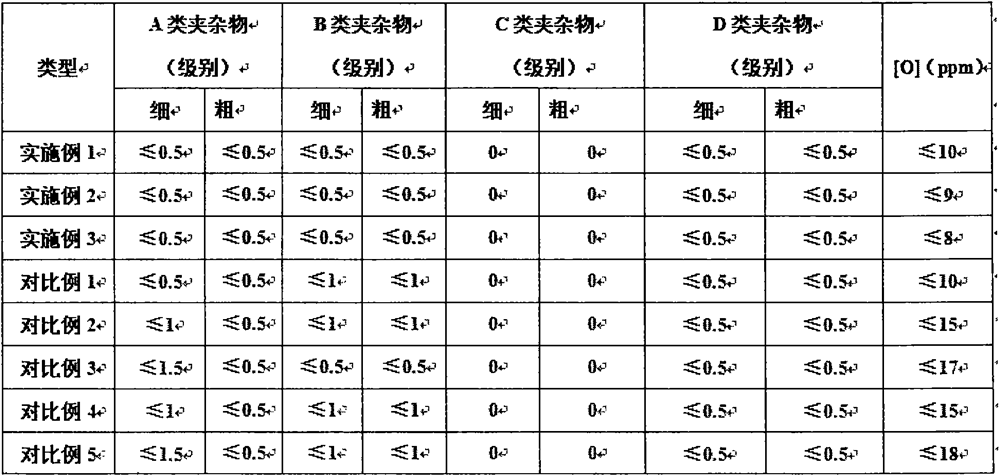

Examples

Embodiment 1

[0038] A preparation method for bearing steel produced by a converter process, including raw material preparation, converter smelting and alloying, LF+RH refining, continuous casting, rolling, and slow cooling; the chemical composition mass percentage content of the controlled bearing steel is: C 1, Si 0.6, Mn 1.30, Mo 0.02, Ni 0.02, Cr 1.75, V 0.005, Al S 0.01, Hf 0.02, Sb 0.001, Cu 0.15, S≤0.025, P≤0.025, [O]≤8×10 -6 , [H]≤2×10 -6 , Yu is Fe and unavoidable impurity; Concrete production steps are as follows:

[0039] (1) Raw material preparation

[0040] The converter with a capacity of 250t is used as the standard raw material, among which molten iron with P≤0.07%, S≤0.02% accounts for 84-86%, and steel scrap with P≤0.07%, S≤0.02%, Ti≤0.05% accounts for 6-8% %, the rest is iron nuggets with P≤0.07%, S≤0.02%;

[0041] (2) Converter smelting

[0042] Converter smelting is adopted, the end-point phosphorus is ≤0.01%, the end-point carbon is ≥0.35%, and the tapping tempera...

Embodiment 2

[0051] A method for preparing bearing steel produced by a converter process, including raw material preparation, converter smelting and alloying, LF+RH refining, continuous casting, rolling, and slow cooling; the chemical composition mass percentage of the bearing steel is controlled to be: C 1.02, Si 0.62, Mn1.32, Mo 0.04, Ni0.03, Cr 1.78, V 0.006, Al S 0.02, Hf 0.025, Sb 0.003, Cu 0.18, S≤0.025, P≤0.025, [O]≤9×10 -6 , [H]≤2×10 -6 , Yu is Fe and unavoidable impurity; Concrete production steps are as follows:

[0052] (1) Raw material preparation

[0053] The converter with a capacity of 250t is used as the standard raw material, among which molten iron with P≤0.07%, S≤0.02% accounts for 84-86%, and steel scrap with P≤0.07%, S≤0.02%, Ti≤0.05% accounts for 6-8% %, the rest is iron nuggets with P≤0.07%, S≤0.02%;

[0054] (2) Converter smelting

[0055] Converter smelting is adopted, the end-point phosphorus is ≤0.01%, the end-point carbon is ≥0.35%, and the tapping temperat...

Embodiment 3

[0064] A method for preparing bearing steel produced by a converter process, including raw material preparation, converter smelting and alloying, LF+RH refining, continuous casting, rolling, and slow cooling; controlling the chemical composition of the bearing steel in mass percentages: C 1.05, Si 0.65, Mn1.35, Mo 0.05, Ni 0.04, Cr 1.8, V 0.008, Al S 0.03, Hf 0.03, Sb 0.004, Cu 0.2, S≤0.025, P≤0.025, [O]≤8×10 -6 , [H]≤2×10 -6 , Yu is Fe and unavoidable impurity; Concrete production steps are as follows:

[0065] (1) Raw material preparation

[0066] The converter with a capacity of 250t is used as the standard raw material, among which molten iron with P≤0.07%, S≤0.02% accounts for 84-86%, and steel scrap with P≤0.07%, S≤0.02%, Ti≤0.05% accounts for 6-8% %, the rest is iron nuggets with P≤0.07%, S≤0.02%;

[0067] (2) Converter smelting

[0068] Converter smelting is adopted, the end-point phosphorus is ≤0.01%, the end-point carbon is ≥0.35%, and the tapping temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com