Preparation method of quantum dots of titanium dioxide doped with holmium, ytterbium and magnesium and application of method in perovskite battery

A perovskite battery and quantum dot technology, applied in the field of solar cells, can solve problems such as hindering electron transmission and poor conductivity, and achieve the effects of expanding the spectral response range, enhancing luminous performance, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

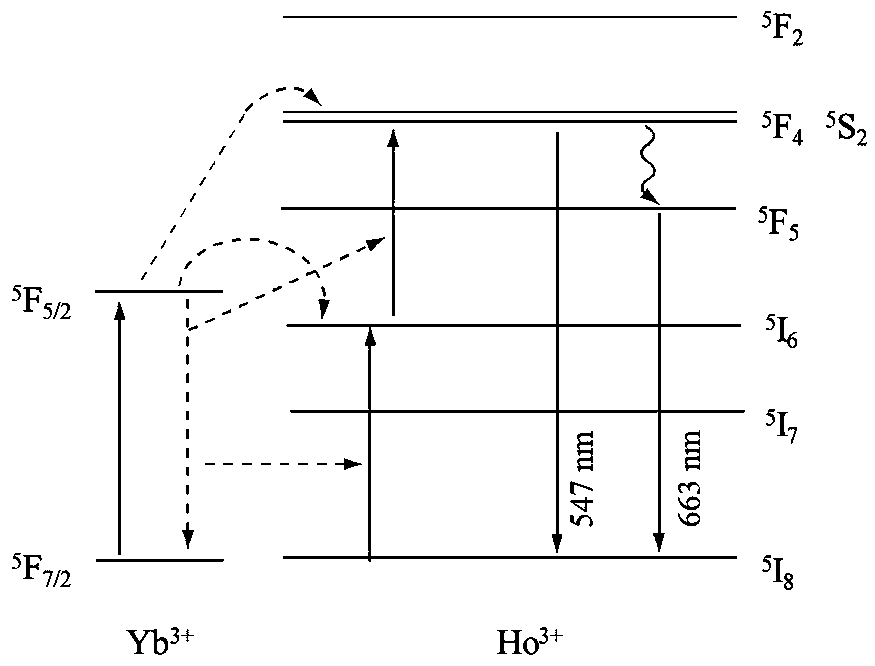

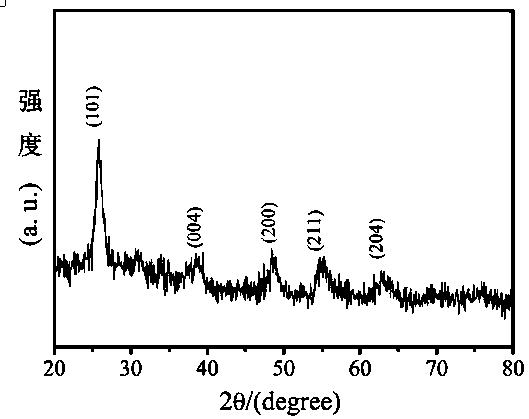

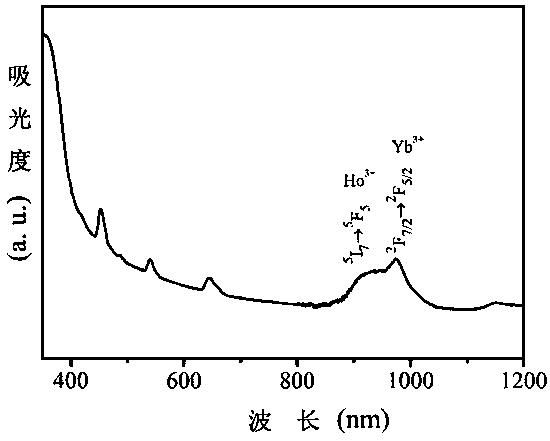

[0039] A Ho 3+ -Yb 3+ -Mg 2+ doped TiO 2 The preparation method of upper quantum dot, it comprises the steps:

[0040] 1) Preparation of TiO2 precursor:

[0041] Mix 0.75 ml of n-tetrabutyl titanate and 0.225 ml of acetylacetone at room temperature for 1 hour, and then add 10 ml of iso-propyl alcohol to obtain solution A;

[0042] Add 0.045 ml of nitric acid and 0.105 ml of deionized water into 5 ml of isopropanol, mix and stir for 1 hour to obtain solution B;

[0043] Solution B was added dropwise to solution A and magnetically stirred for 6 hours to obtain TiO 2 precursor solution.

[0044] 2) Preparation of quantum dots: Ho(NO 3 ) 3 ·5H 2 O, Yb(NO 3 ) 3 ·5H 2 O and Mg(NO 3 ) 2 ·6H 2 O joins TiO 2 In the precursor solution, a mixed solution C is obtained, and the molar ratios of Ho and Ti, Yb and Ti, Mg and Ti in the mixed solution C are 0.5~1.5:100, 1~5:100, 1~4:100 respectively;

[0045] Dry the mixed solution C at 100°C for 12 hours (remove the solvent), ...

Embodiment 2

[0054] In this example, the mixed solution C prepared in Example 1 is used to participate in the preparation of the perovskite battery of this example, and the specific preparation method is as follows:

[0055] 1) FTO glass sheet treatment: clean the FTO glass sheet and treat it with ultraviolet light for 20 min to obtain a clean FTO glass sheet; the specific method of FTO glass cleaning is: etching (that is, using Zn powder and dilute hydrochloric acid The FTO glass slices were etched), and the FTO glass slices were placed in conductive glass cleaning solution, acetone and isopropanol in sequence, and ultrasonically cleaned for 20 minutes each.

[0056] 2) Preparation of a dense layer: Add 0.072 ml of titanium acetylacetonate to 1 ml of n-butanol and mix evenly to obtain a dense layer precursor. Drop the dense layer precursor solution on the clean FTO glass sheet obtained in step 1), and mix at 3500 spin coating at a speed of 30 s per minute, and then annealed at 500ºC for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| short-circuit current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com