Arrangement method of outgoing line of hydropower station behind dam

A technology of outgoing line layout and hydropower station, which is applied in the details of substation/switch layout, hydropower station, busbar/line layout, etc. It is convenient for operation and maintenance management, improves safe and reliable operation, and has the effect of small inspection and maintenance scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following Mentioned examples.

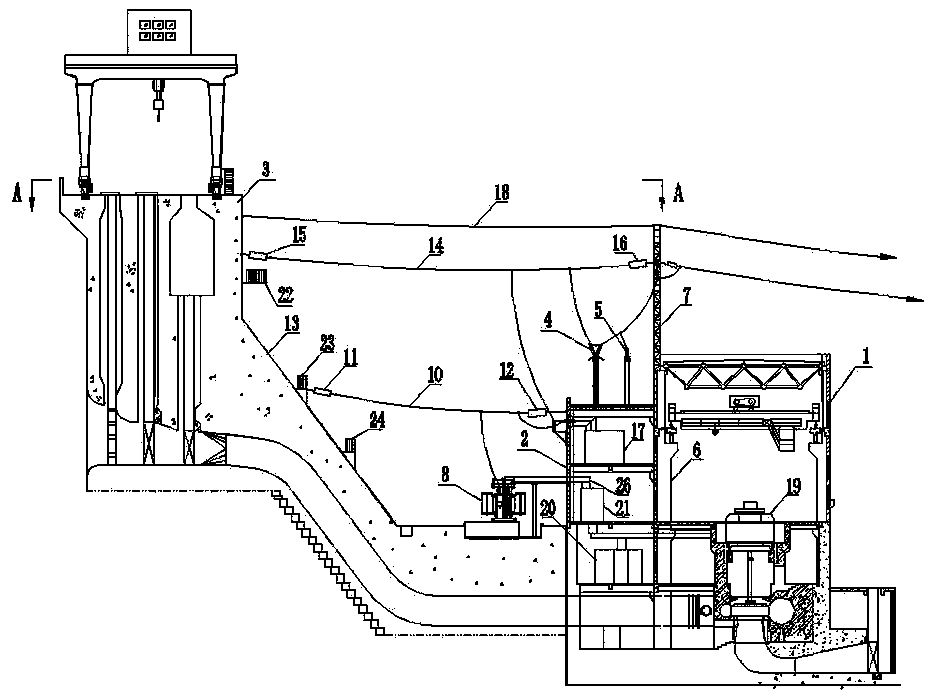

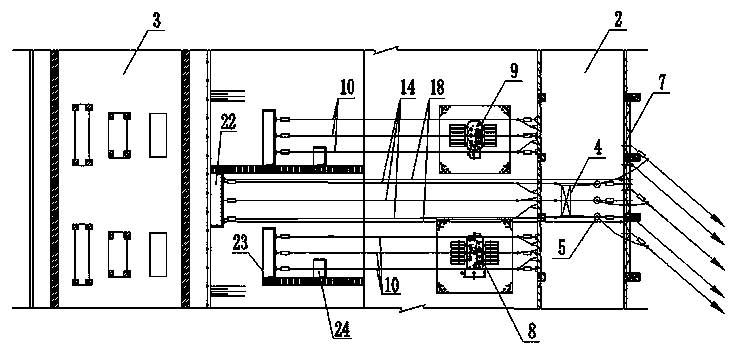

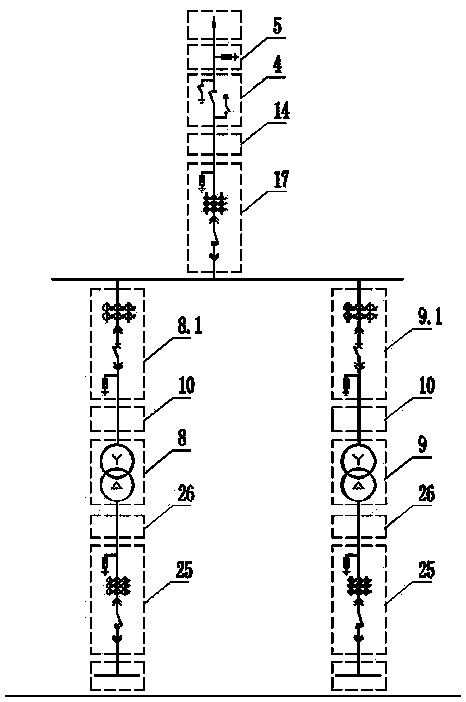

[0025] Such as Figure 1-3 As shown, the method for arranging outgoing lines of a dam-type hydropower station of the present invention utilizes the three-dimensional space between the main powerhouse 1, auxiliary powerhouse 2 and the dam body 3 of the hydropower station building, and arranges the main transformer on the ground of the three-dimensional space and the overhead conductors in the upper space ; Outgoing isolation switch 4 and outgoing arrester 5 are arranged on the roof of auxiliary building 2, and a gate-type outlet frame 7 is set on the roof of the common structural colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com