A kind of gas discharge reactor, gas discharge system and preparation method of trichlorosilane

A gas discharge and reactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes of applying energy, silicon compounds, etc. The effect of low loss and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

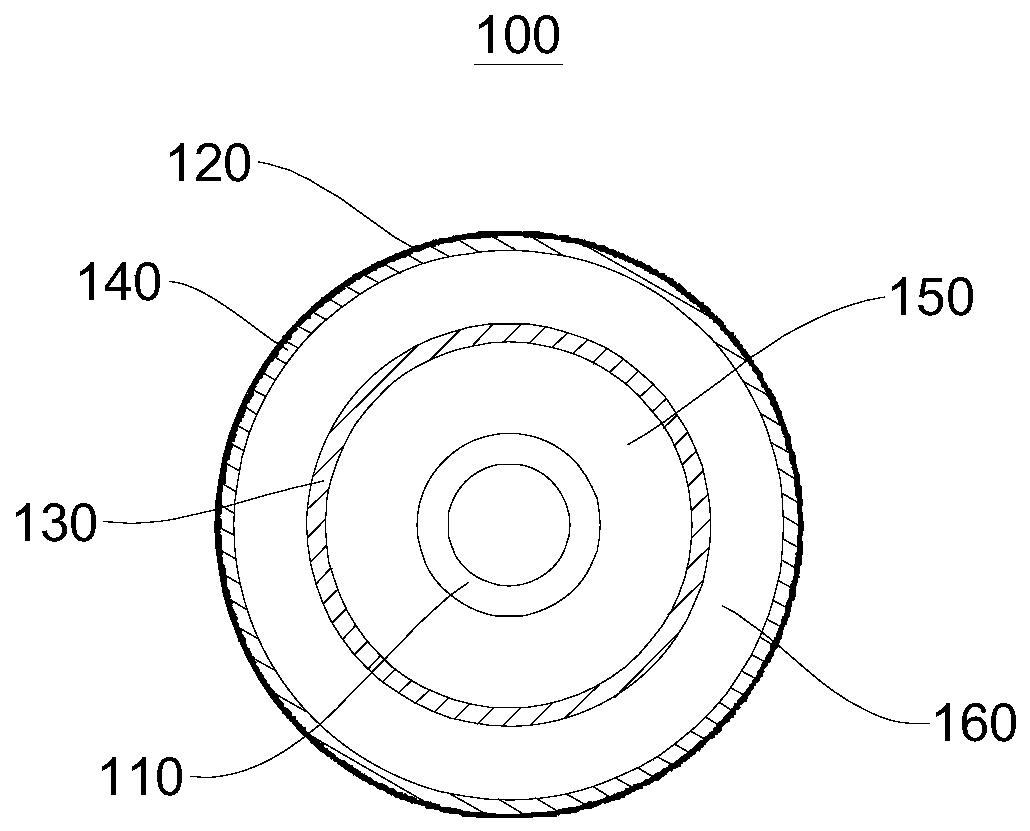

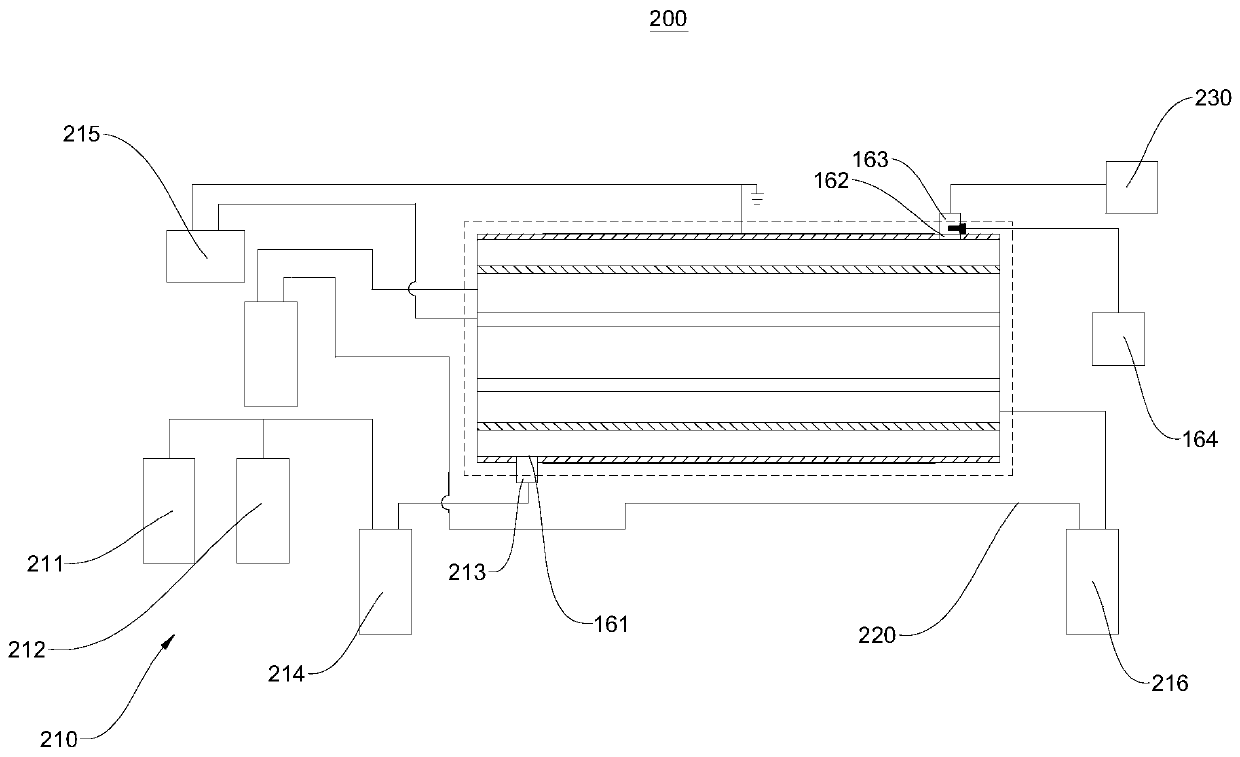

[0035] see figure 1 , a gas discharge reactor 100 includes an inner electrode 110, an outer electrode 120, a first dielectric 130 and a second dielectric 140, the outer electrode 120 is arranged outside the inner electrode 110, the second dielectric 140 is arranged in the outer electrode 120, the first The dielectric 130 is arranged between the inner electrode 110 and the outer electrode 120, a rare gas discharge chamber 150 is formed between the inner electrode 110 and the first dielectric 130, and a material gas discharge chamber 160 is formed between the first dielectric 130 and the outer electrode 120, The gas discharge reactor 100 has a material gas inlet 161 and a material gas outlet 162 . Both the material gas inlet 161 and the material gas outlet 162 are arranged on the outer electrode 120 and communicate with the material gas discharge chamber 160 .

[0036] During use, the rare gas passes through the rare gas discharge chamber 150, and the material gas passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com